Mold cutting device of mold cutting machine and method for adjusting mold cutting depth of mold cutting machine

A die-cutting machine and die-cutting technology, applied in metal processing and other directions, can solve the problem of difficulty in accurately controlling the depth of die-cutting, and achieve the effect of ensuring the quality of die-cutting products, high efficiency and low processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of application of the present invention.

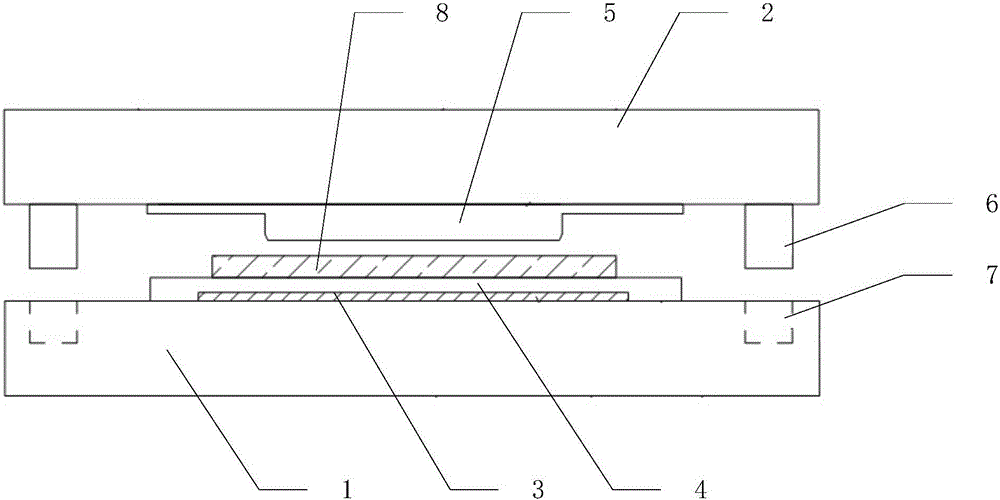

[0025] Please refer to figure 1 After starting the die-cutting machine and adjusting the relevant parameters, install the mold, which is mainly composed of the lower template 1 and the upper template 2. Pave a piece of carbon paper 3 on the lower template 1, the size is 200*120mm, and then cover a piece of polyethylene terephthalate film on the carbon paper as a buffer pad 4, the size of the buffer pad 4 is 250*160mm, and the thickness is 0.25mm, and glue the buffer pad 4 on the lower template 1 with double-sided tape, and place the carbon paper in the middle area of the buffer pad 4. Install the cutting die 5 on the upper template 2. The cutting die 5 is designed and customized according to the size of the processed pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com