Powder Spreading Device of Electron Beam Rapid Prototyping Machine

A powder spreading device and molding machine technology, which is applied in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of metal powder particles collapsing and affecting the forming of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

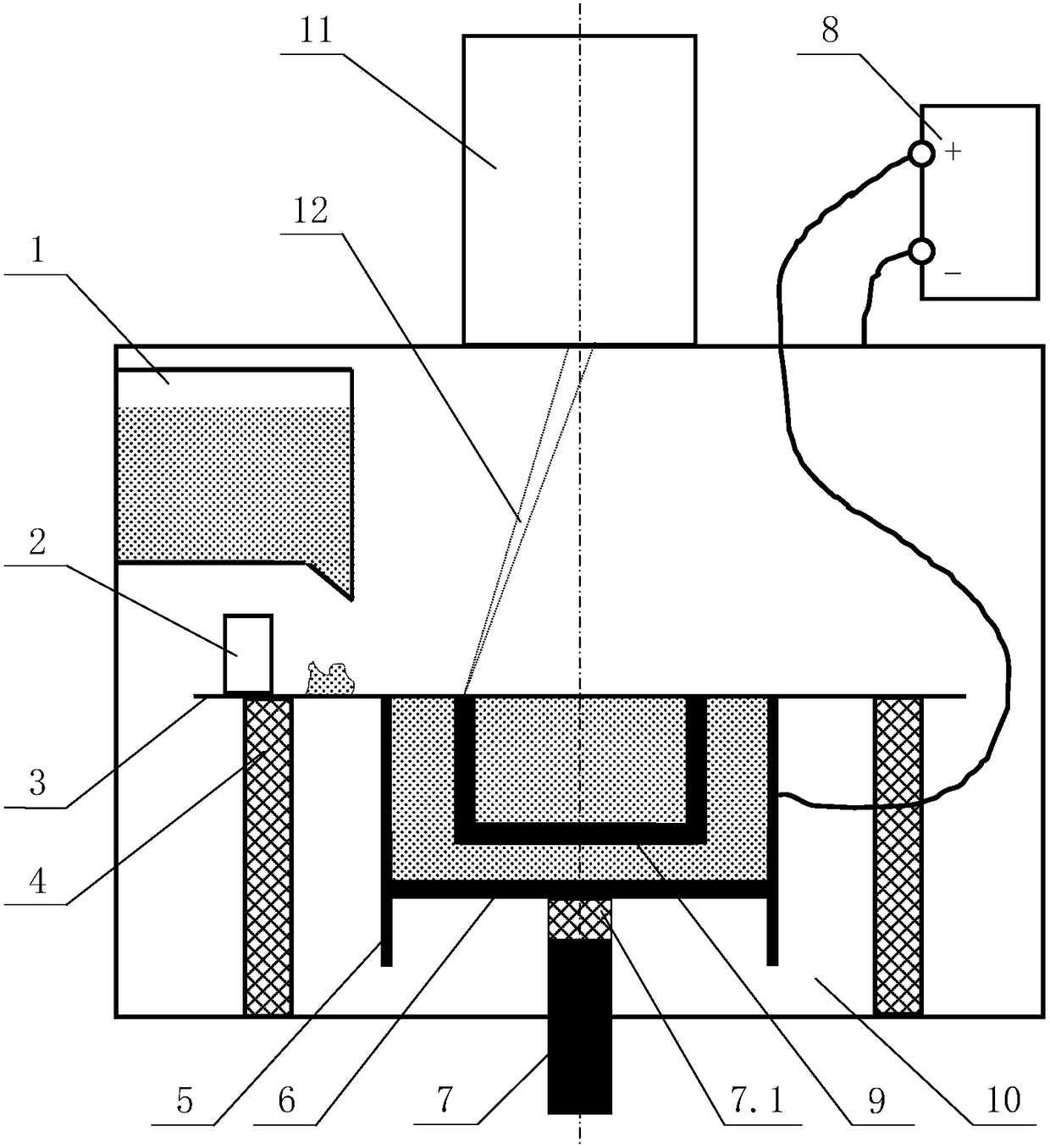

[0012] A powder spreading device for an electron beam rapid prototyping machine, such as figure 1 As shown, it includes a powder filling box 1, a powder spreading device 2, a powder spreading platform 3, a support rod 4, a forming cylinder 5 and a DC power supply 8.

[0013] The powder filling box 1, the powder spreader 2, the powder spread platform 3 and the forming cylinder 5 are placed in the working chamber 10, which is an airtight vacuum chamber. The powder spreading platform 3 is in the middle of the working room 10, and the powder spreading platform 3 is fixed on the bottom of the working room 10 by the support rod 4. The powder spreading device 2 is movably placed on the upper surface of the powder spreading platform 3 . The powder filling box 1 is suspended above the powder spreading platform 3 . The forming cylinder 5 is fixed on the lower surface of the powder spreading platform 3 . The inside of the forming cylinder 5 is provided with a lifting platform 6, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com