Preparation method of catalyst for synthesizing glycerol carbonate through urea method

A technology of glycerin carbonate and catalyst, applied in the application field of glycerin, which can solve the problems of low reaction yield of glycerin and urea, achieve good industrialization prospects, save resources, and reduce environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of zinc glycerol: Mix 2 g of zinc acetate and 10 g of glycerin and stir at 160°C for 5 hours under reflux. After stirring, transfer the mixture to a 100mL reaction kettle, react hydrothermally at 150°C for 18 hours, cool, and filter the mixture. After washing with pure water for 3 times, dry at 80°C for 12 hours, and the obtained white solid is zinc glycerol;

[0016] Calcination: The obtained white solid was calcined at 550° C. for 3 h at a heating rate of 2° C. / min to obtain the metal oxide catalyst zinc oxide.

Embodiment 2

[0018] Under the situation that the preparation condition of catalyzer is exactly the same as embodiment 1, only the mass ratio of zinc acetate and glycerin in the preparation method is 1: 10 changed into 1: 5, 1: 9, 1: 13, 1: 17, 1:20, five metal oxide catalysts were obtained.

Embodiment 3

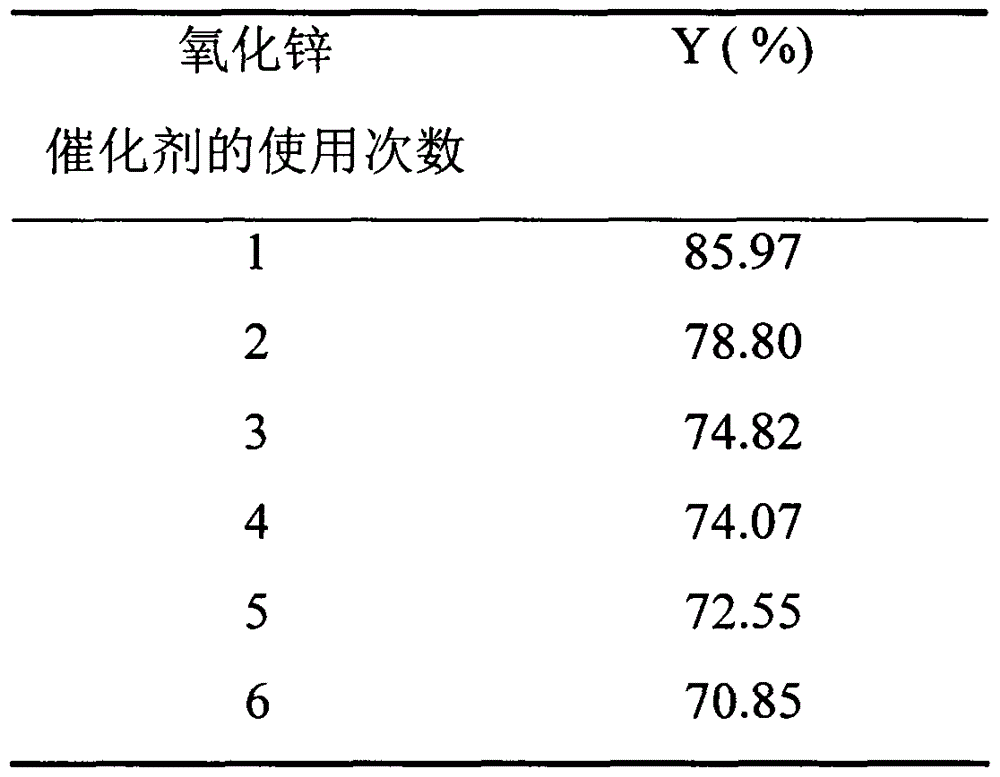

[0020] Accurately weigh 2.3g of analytically pure glycerin and add it to a 100mL three-necked round-bottomed flask, preheat it under the oil to the set temperature, then add a certain amount of urea and metal oxide catalyst into the three-necked round-bottomed flask, under the action of magnetic stirring After reacting under reduced pressure for a period of time, add a certain amount of methanol to the product and centrifuge to separate the catalyst. The separated supernatant was used for yield analysis by gas chromatography, and the solid catalyst at the bottom was recovered by washing and drying with methanol.

[0021] With the metal oxide catalysts of Example 1 and Example 2, the amount of catalyst is a certain value, the reaction temperature is a certain value, the molar ratio of glycerol to urea is a certain value, and the reaction time is a certain value, 1.0kPa. When the mass ratio of zinc acetate to glycerol is a certain value, the yield of glycerol carbonate reaches t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com