Grouping-cascade-type permanent magnet coupling

A permanent magnet coupling, grouping-level technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve problems such as difficulty in heat dissipation, and achieve the effects of simple maintenance, simple structure, and simple mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

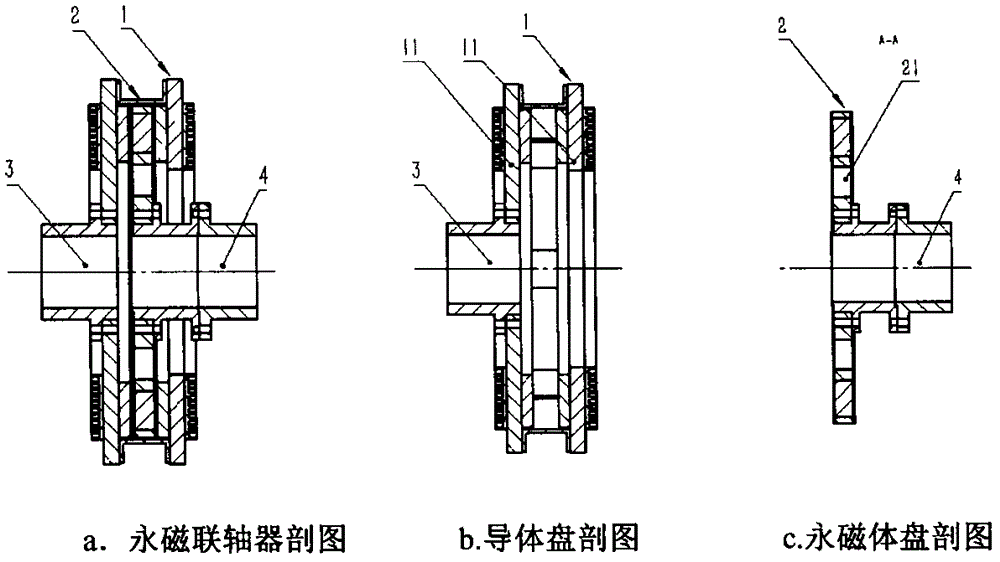

[0019] see figure 1 , 2 , 3, the grouped cascaded permanent magnet coupling in this embodiment is composed of a conductor disc 1, a permanent magnet disc 2, a motor shaft connection flange 3, and a load shaft connection flange 4; the conductor disc 1 passes through The motor shaft connection flange 3 is installed on the motor shaft, the conductor disk 1 and the motor shaft maintain synchronous speed; the permanent magnet disk 2 is installed on the load shaft through the load shaft connection flange 4, and the permanent magnet disk 2 and the load shaft maintain synchronous speed; The conductor disc 1 and the permanent magnet disc 2 are not in contact with each other, and generate driving force and transmit torque through relative motion, so as to achieve the purposes of flexible transmission, effective vibration isolation, high efficiency and energy saving, and improved heat dissipation efficiency.

[0020] see figure 1 , 2 , 3, and 4, the grouped cascaded permanent magnet c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com