Trace oil injection device

An oil injection device and micro-quantity technology, which is applied in the direction of quantitative devices, distribution devices, lubricating oil control valves, etc., can solve the problems of high-frequency oil injection, low utilization rate of lubricating oil, limited application range, etc., and avoid waste of lubricating oil , improve service life and save lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

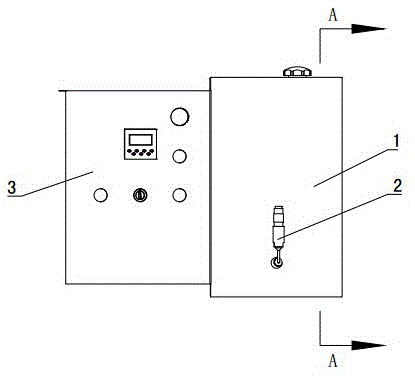

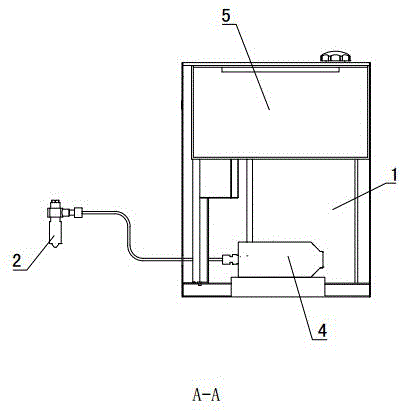

[0036] Such as Figure 1~2 As shown: the oil tank 5, the oil pump 4 and the control device are installed in the box body 1, and the oil outlet nozzle 2 is arranged outside the box body 1. The box body 1 is a cuboid, and the box body 1 is provided with a box body door 3, and a control button and a display screen are installed on the box body door 3, which are used to control the micro-greasing device and display the working state of the micro-greasing device.

[0037] Fuel tank 5 is installed on the top of casing 1, and the filling port of fuel tank 5 is arranged on the top, and stretches out the top surface of casing 1, and fuel tank 5 is plexiglass material, and is provided with strainer at the oil inlet, ensures that fuel tank 5 The lubricating oil inside is clean and pollution-free.

[0038] The oil pump 4 is installed in the lower middle part of the casing 1, and the oil inlet of the oil pump 4 is communicated with the oil outlet at the bottom of the oil tank 5 through a ...

Embodiment 2

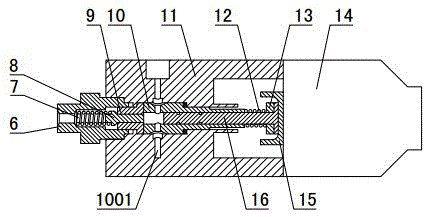

[0059] Such as Figure 5As shown: the difference between embodiment 2 and embodiment 1 is: the right end of the plunger 16 is provided with a plunger oil hole 1601, the plunger oil hole 1601 is "L" shaped, and the end of the vertical part of the plunger oil hole 1601 It is arranged on the side of the plunger 16 , the end of the horizontal part of the plunger oil hole 1601 is arranged on the end surface of the right end of the plunger 16 , and the pump oil chamber is located on the right side of the plunger 16 . When the plunger 16 moves rightward to the left dead center of the stroke, the volume of the pump oil chamber is the largest. At this time, the plunger oil hole 1601 communicates with the plunger sleeve oil hole 1001, and the lubricating oil enters the pump oil chamber along the plunger oil hole 1601. , and when the plunger 16 moves to the right, the lubricating oil in the pump oil chamber is pumped out. The plunger oil hole 1601 can limit the lubricating oil entering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com