Construction method of washboard road in test track

A construction method, washboard road technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of easy deformation, short service life, poor road durability, etc., and it is not easy to deform when it reaches the service life, ensuring the quality of the road surface and the durability of the road surface strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

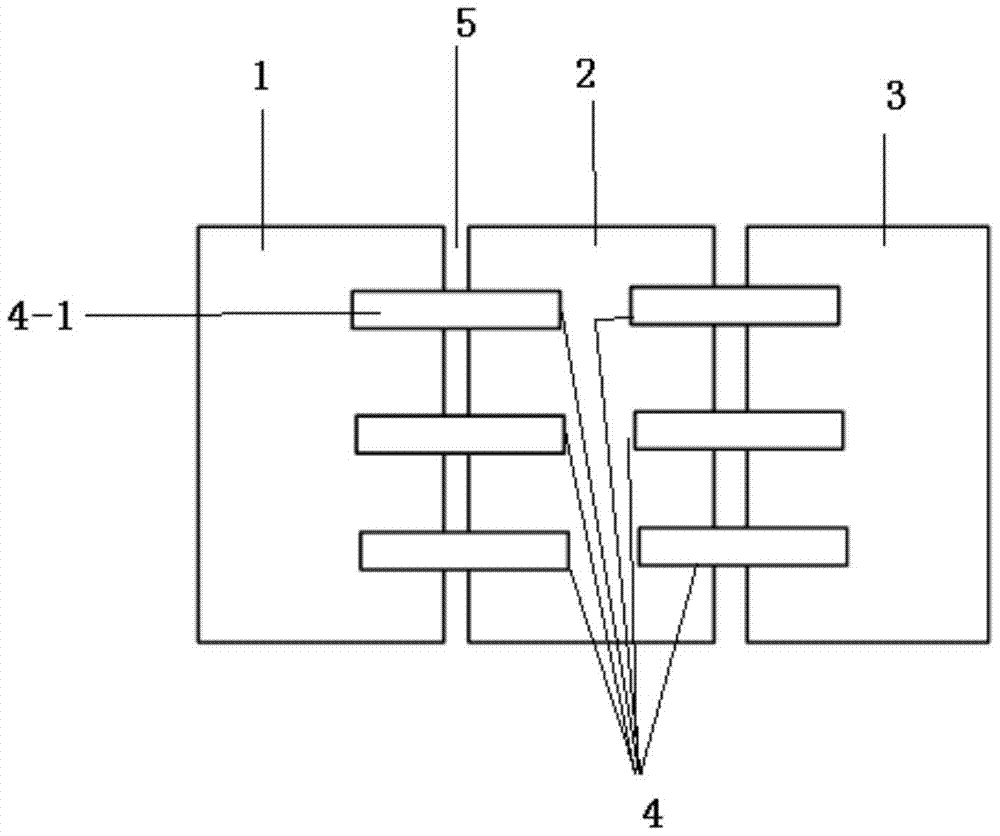

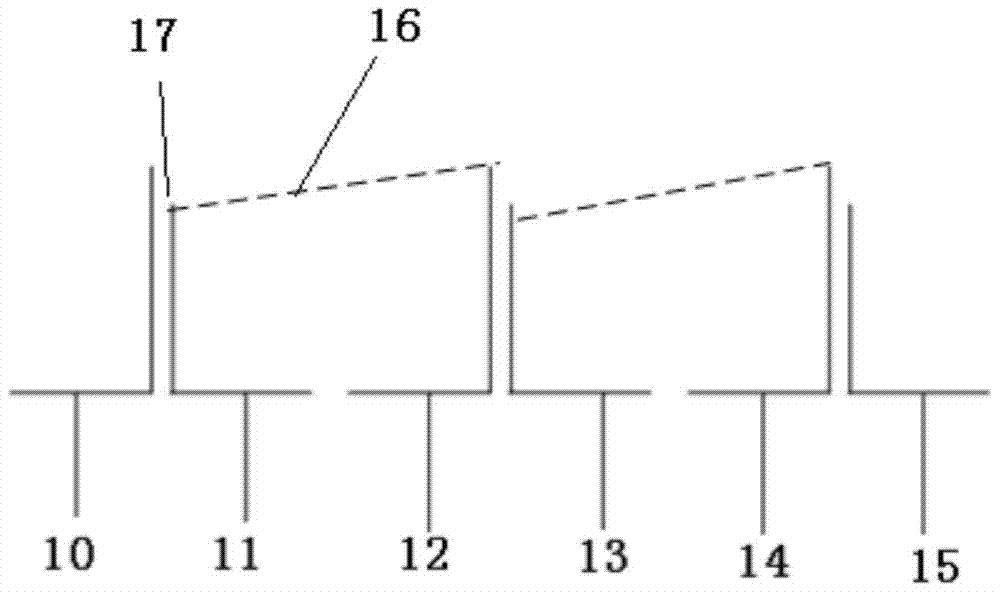

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

[0049] The invention provides a construction method for a washboard road in a test field. The road surface structure of the washboard road is cement concrete, and the road surface is a washboard shape. The washboard road can be a washboard road with a width of 3.5m and a length of 100m; the construction method comprises the following steps:

[0050] Step 1, according to the construction design drawings, use the total station to accurately stake out the left and right lines of the road surface;

[0051]Step 2, set the left formwork of the concrete base along the left line, and set the right formwork of the concrete base along the right line; wherein, the formwork materials of the left formwork of the concrete base and the right formwork of the concrete base are channel steel, and are fixed with T-shaped diagonal braces to ensure concrete pouring There is no displacement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com