Dyeing wastewater advanced treatment device

A technology for advanced treatment of printing and dyeing wastewater, applied in textile industry wastewater treatment, multi-stage water treatment, special compound water treatment, etc. , to achieve the effect of convenient maintenance, realization of sewage recycling, and low investment in infrastructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

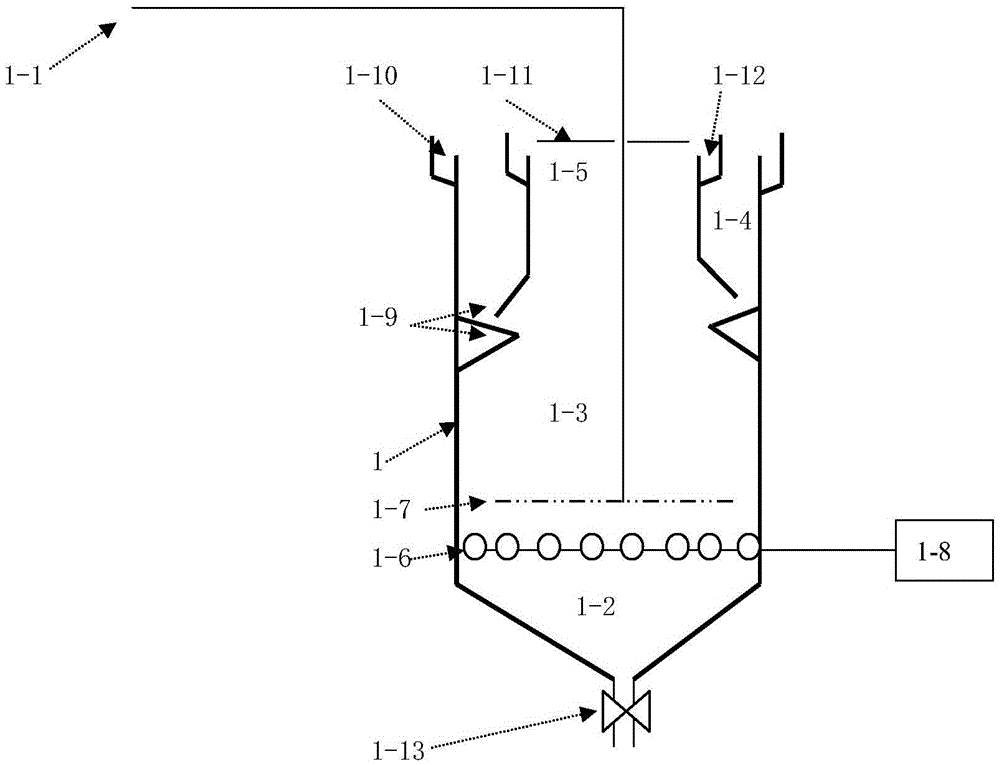

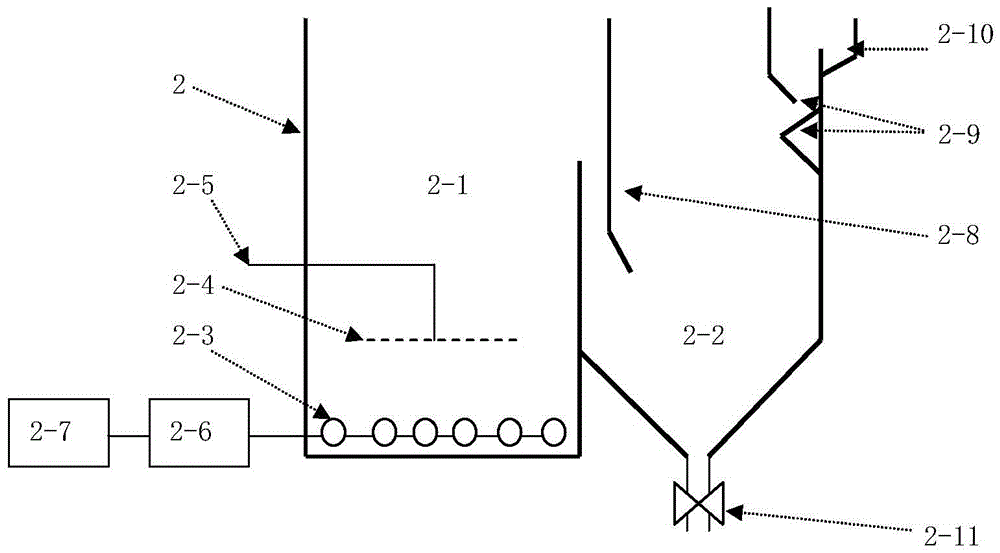

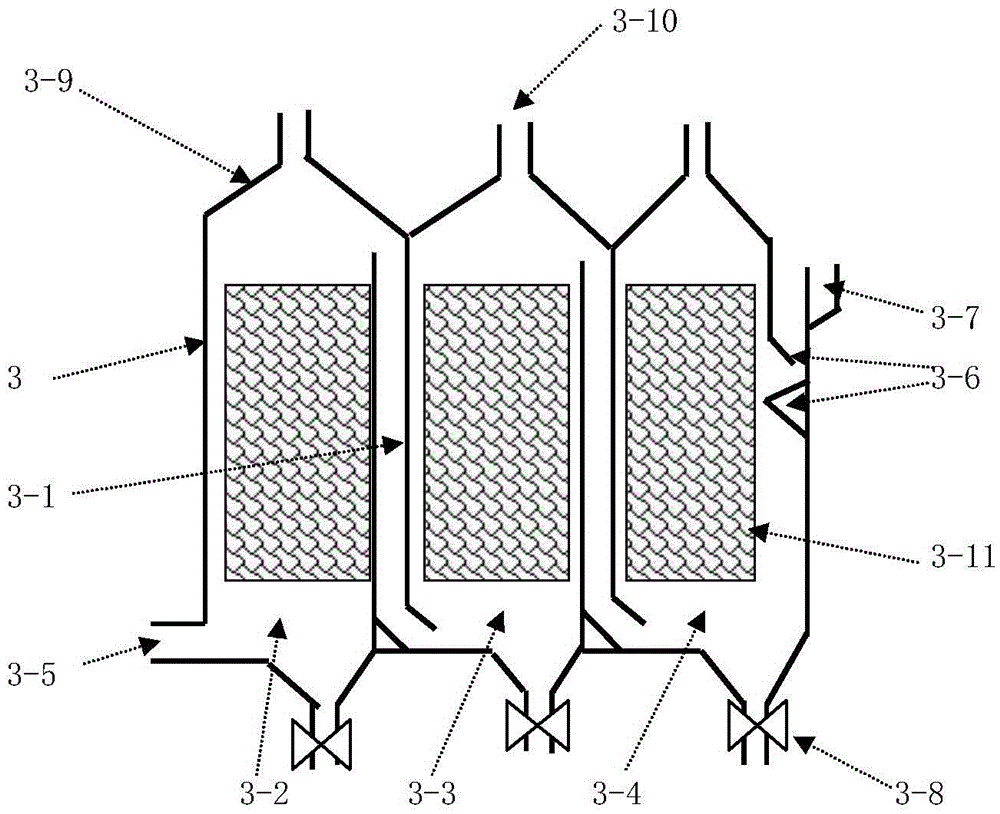

[0037] Such as Figure 1 to Figure 6 As shown, a printing and dyeing wastewater advanced treatment device of the present invention includes a regulating tank, an air flotation tank 1, an advanced oxidation sedimentation tank 2, and an improved packing type A 2 O pond 3, reverse flow aeration filter pond 4 and stabilization pond 5; the regulating pond, air flotation pond 1, advanced oxidation sedimentation pond 2, improved packing type A 2 The O pond 3, the reverse flow aeration filter pond 4 and the stabilizing pond 5 are connected in sequence.

[0038] The regulating pond includes a regulating pond inlet pipe and a regulating pond outlet pipe for regulating the water quality and quantity of the printing and dyeing wastewater.

[0039] The air flotation tank 1 includes an air flotation tank inlet pipe 1-1 and an air flotation tank outlet pipe for discharging treated water, and the air flotation tank is sequentially composed of mud sand area 1-2, mixing area 1-3 and separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com