A material stacking machine

A technology of materials and manipulators, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of time-consuming and laborious, and achieve the effect of liberating labor force, high work efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

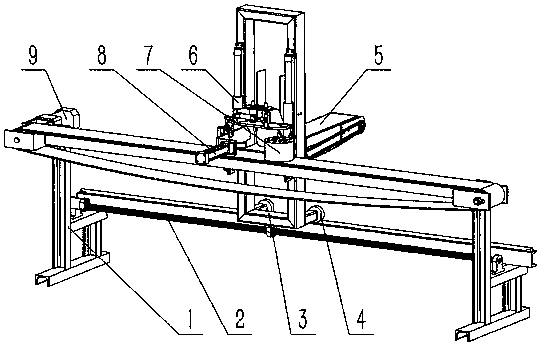

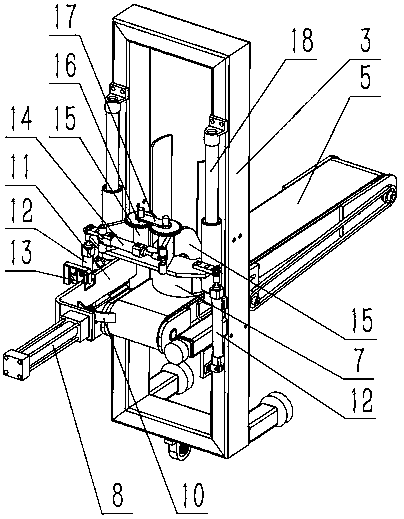

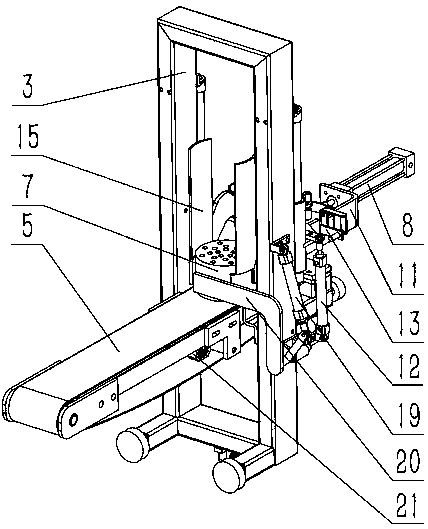

[0015] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a material stacking machine includes a main transmission frame 1 and an auxiliary transmission frame 5, a main body frame 3, a feeding cylinder 8, two lifting cylinders 12 and two manipulators 15, a baffle plate 20 and a baffle plate cylinder 19, Lifting plate 22, clamping cylinder 14. Main transmission frame 1 end is provided with main transmission motor 9, and main transmission motor 9 links to each other with the conveyer belt on the main transmission frame 1 by roller. The middle part of the main transmission frame 1 is equipped with a screw 2 and a cylindrical slide rail. One side of the main frame 3 is installed on the screw 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com