External page turning mechanism and page turning mechanism operation method

A technology of mechanism movement and turning mechanism, which is applied in printing, books, bookmarks, etc., can solve the problems of unfavorable continuous mechanized operation of the complete bookbinding production line, consume manpower, increase costs, etc., achieve a high degree of mechanization and automation, save labor, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

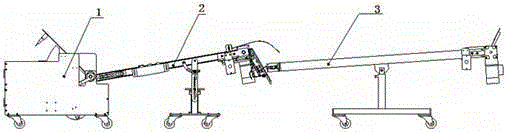

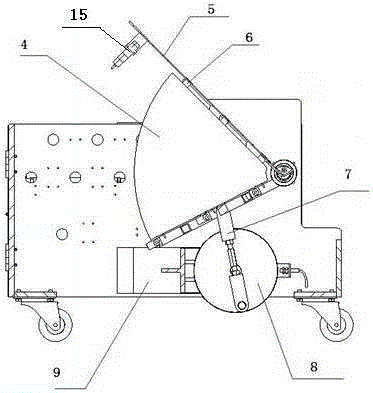

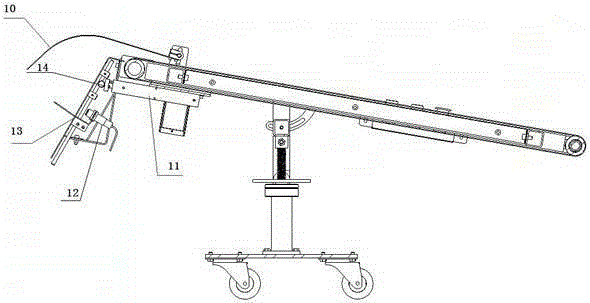

Embodiment 1

[0029] The technical scheme of the present invention is: a page-turning mechanism, comprising a primary turning mechanism 1, a conveying roller table 3 and a secondary turning mechanism 2, the primary turning mechanism 1 is connected to the left end of the conveying roller table 3, and the secondary turning mechanism 2 is connected to the conveying roller table The right end of the roller table 3 is connected, and the primary turnover mechanism 1 includes a vacuum suction nozzle 6 and a cam linkage mechanism. The cam linkage mechanism includes a cam plate 8 and a support link 7. 7 is fixed with the lower end of the support plate 4, and the secondary turning mechanism 2 includes a push rod 14 and a push cylinder 11, and the push cylinder 11 drives the push rod 14 to perform linear motion, and the number of vacuum suction nozzles 6 is provided with one, and the support plate 4 and The support panel 5 is fixedly connected, the upper end of the support panel 5 is provided with a pr...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that this embodiment is provided with two vacuum suction nozzles.

Embodiment 3

[0035] The difference between this embodiment and Embodiment 1 is that this embodiment is provided with three vacuum suction nozzles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com