Control system for automatic supply of ink source of printing machine

An automatic supply and control system technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve problems such as environmental pollution, low efficiency, ink waste, etc., to reduce environmental pollution, eliminate waste, and improve automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment, further illustrate the present invention.

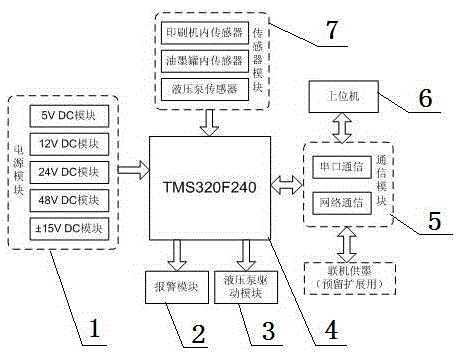

[0023] see figure 1 It can be seen that a control system for automatic supply of ink sources for printing machines includes a processor 1 , a power supply module 2 , a sensor module 3 , a signal conditioning module 4 , a hydraulic pump drive module 5 , an alarm module 6 , and a communication module 7 .

[0024] The power supply module 2 , signal conditioning module 4 , hydraulic pump driving module 5 , alarm module 6 and communication module 7 are all connected to the processor 1 .

[0025] The sensor module 3 is provided with an ink volume sensor for the printing machine ink box, an ink volume sensor in the ink tank, and a hydraulic pump state sensor. The sensor module 3 is connected with the signal conditioning module 4 .

[0026] The core of the entire control system can use a 16-bit microprocessor 1 to realize the detection and control of the amount of ink in the ink cartridge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com