Large steel plate splicing method and device

A splicing device, steel plate technology, applied in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of many welding defects, many processes, large welding deformation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings.

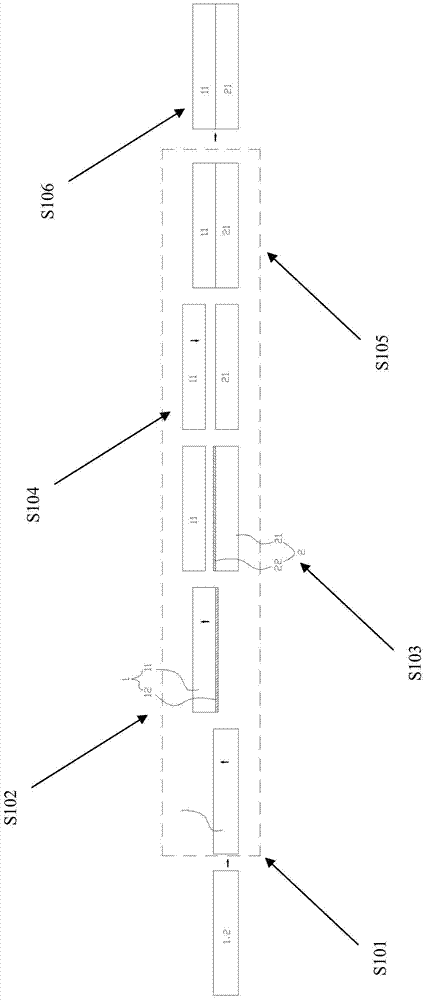

[0040] see figure 1 , figure 1 It is a schematic flow chart of the first embodiment of the large-scale steel plate splicing method of the present invention. It roughly includes the following steps:

[0041] S101, sending the first steel plate 1 vertically and horizontally to the first station;

[0042] S102. Horizontally move the first steel plate 1 from the first station to the cutting position on the side to be spliced and be clamped, perform laser cutting along the straight line X, remove the cutting edge 12, and then make the cut The main body 11 of the first steel plate 1 is laterally displaced outward by a set distance to the second station, and kept clamped;

[0043] S103. Send the second steel plate 2 vertically and horizontally to the first station and clamp it, and perform laser cutting along the straight line X, remove the cutting edge 22, and the mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com