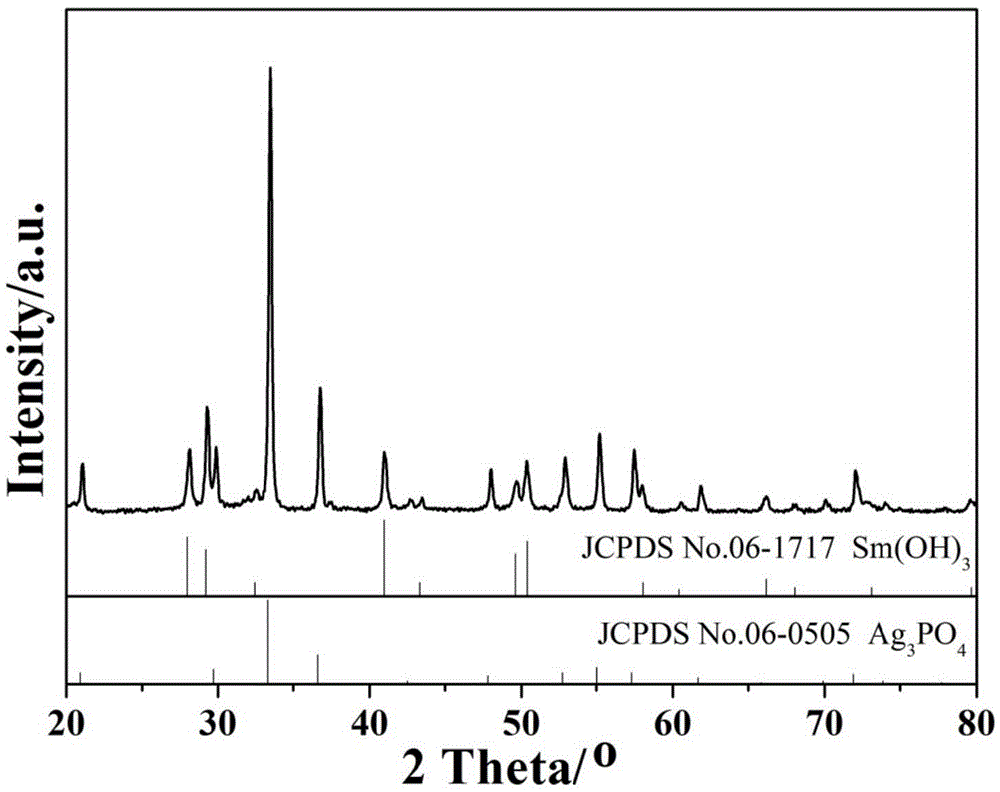

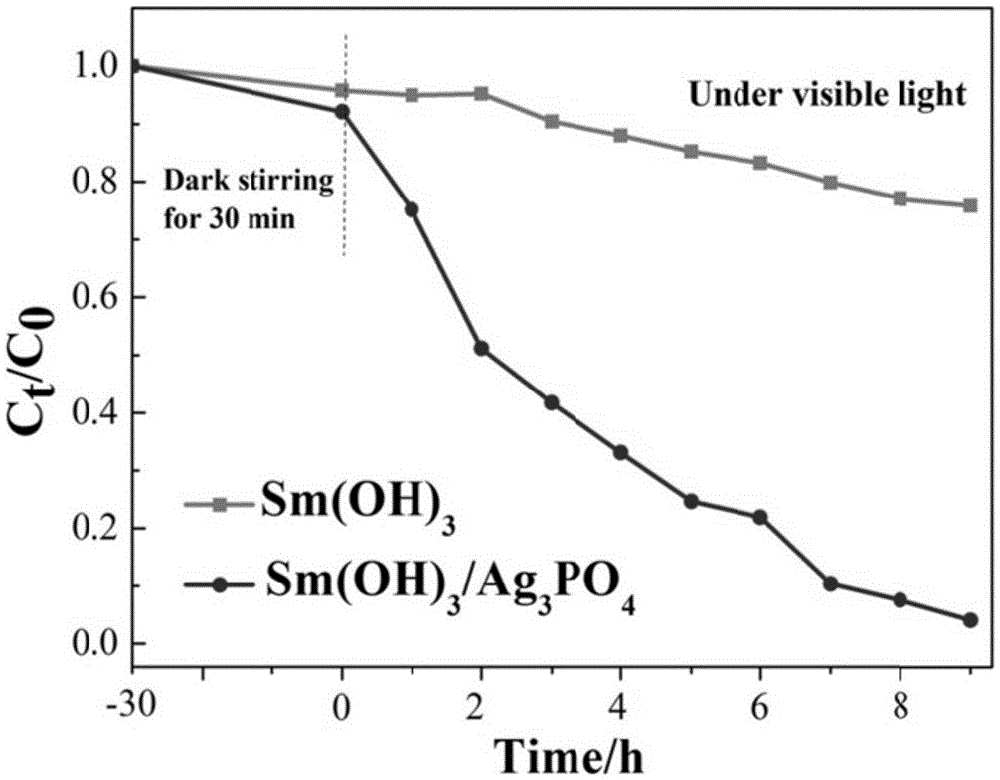

Method for preparing Sm(OH)3/AgPO4 nanocomposite by virtue of in-situ deposition method

A nano-composite and in-situ deposition technology, applied in the field of nano-semiconductor composite materials, can solve the problems of low visible light response and solar energy utilization rate of only 1%, and achieve strong visible light response, stable visible light response, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation of Sm(OH) by in-situ deposition method 3 / AgPO 4 A method for a nanocomposite comprising the steps of:

[0029] 1) A certain amount of analytically pure Sm(NO) 3 ·6H 2 O was dissolved in appropriate amount of distilled water to prepare 60mLSm 3+ Solution A with a concentration of 1mol / L; add 0.2mL of analytically pure diethylenetriamine dropwise to solution A, and continue stirring for 0.5h to form a reaction precursor;

[0030] 2) Pour the reaction precursor solution into the microwave hydrothermal reaction kettle, seal the kettle and put it into the microwave hydrothermal reaction instrument (MDS-10 type), react at 200°C for 0.5h, and naturally cool to room temperature after the reaction; the product Sequentially wash with distilled water and absolute ethanol for 4 to 6 times, collect the product and dry it in vacuum at 80°C for 2 hours to obtain Sm(OH) 3 product.

[0031] 3) Add 0.2g of Sm(OH) 3 Place in 60mL of distilled water and perform ultras...

Embodiment 2

[0034] 1) A certain amount of analytically pure Sm(NO) 3 ·6H 2 O was dissolved in appropriate amount of distilled water to prepare 60mLSm 3+ Solution A with a concentration of 0.8mol / L; add 0.28mL of analytically pure diethylenetriamine dropwise to solution A, and continue stirring for 1h to form a reaction precursor;

[0035]2) Pour the reaction precursor liquid into the microwave hydrothermal reaction kettle, seal the kettle and put it into the microwave hydrothermal reaction instrument (MDS-10 type), react at 80°C for 0.5h, and naturally cool to room temperature after the reaction; the product Sequentially wash with distilled water and absolute ethanol for 4 to 6 times, collect the product and dry it in vacuum at 60°C for 2 hours to obtain Sm(OH) 3 product.

[0036] 3) Add 0.2g of Sm(OH) 3 Put it into 50mL of distilled water and carry out ultrasonic dispersion for 30min, prepare 50mL of silver nitrate solution with a concentration of 0.04mol / L and add Sm(OH) dropwise 3...

Embodiment 3

[0039] 1) A certain amount of analytically pure Sm(NO) 3 ·6H 2 O was dissolved in appropriate amount of distilled water to prepare 40mLSm 3+ Solution A with a concentration of 0.5mol / L; add 0.2mL of analytically pure diethylenetriamine dropwise to solution A, and continue stirring for 1 hour to form a reaction precursor;

[0040] 2) Pour the reaction precursor solution into the microwave hydrothermal reaction kettle, seal the kettle and put it into the microwave hydrothermal reaction apparatus (MDS-10 type), react at 100°C for 2 hours, and cool to room temperature naturally after the reaction; the products are sequentially Centrifuge and wash with distilled water and absolute ethanol for 4 to 6 times, collect the product and dry it in vacuum at 80°C for 0.5h to obtain Sm(OH) 3 product.

[0041] 3) Add 0.2g of Sm(OH) 3 Place in 40mL of distilled water and perform ultrasonic dispersion for 10min, prepare 50mL of silver nitrate solution with a concentration of 0.01mol / L and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com