Production process of steamed cake with filler

A production process, steamed cake technology, which is applied in the field of filling steamed cake production process, can solve the problems of vitamin and mineral decline, insufficient steamed cake rise, easy overflow or cracking, etc., to increase taste and facilitate Filling amount, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further description will be given below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

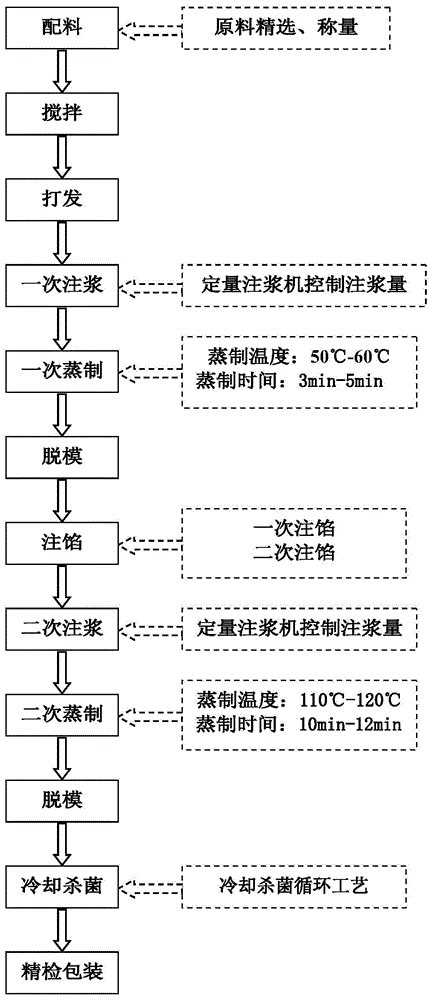

[0026] Such as figure 1 Shown, a kind of production technique of filling steamed cake, concrete steps are as follows:

[0027] Step (1) Ingredients: check and accept raw materials according to the corresponding national standards, select suitable raw materials for steamed cakes and suitable as fillings, and accurately weigh them for use according to the addition amount requirements;

[0028] Step (2) Stirring: first add the wet raw materials into the blender and stir, then add the dry raw materials, and fully stir the raw materials to absorb each other, completely uniform;

[0029] Step (3) Sending: After stirring, the raw materials are fully stirred with a cake automatic sending machine, and the viscosity is properly adjusted or added raw materials through the inspection of the viscosity until the cake batter standard is reached; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com