Grass storage frame

A technology of grass frame and support column is applied in the field of grass storage frame for green hay, scattered grass and straw bales, which can solve the problems of backwardness, inability to build sheltered forage in time, and inability to meet the feeding needs of livestock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

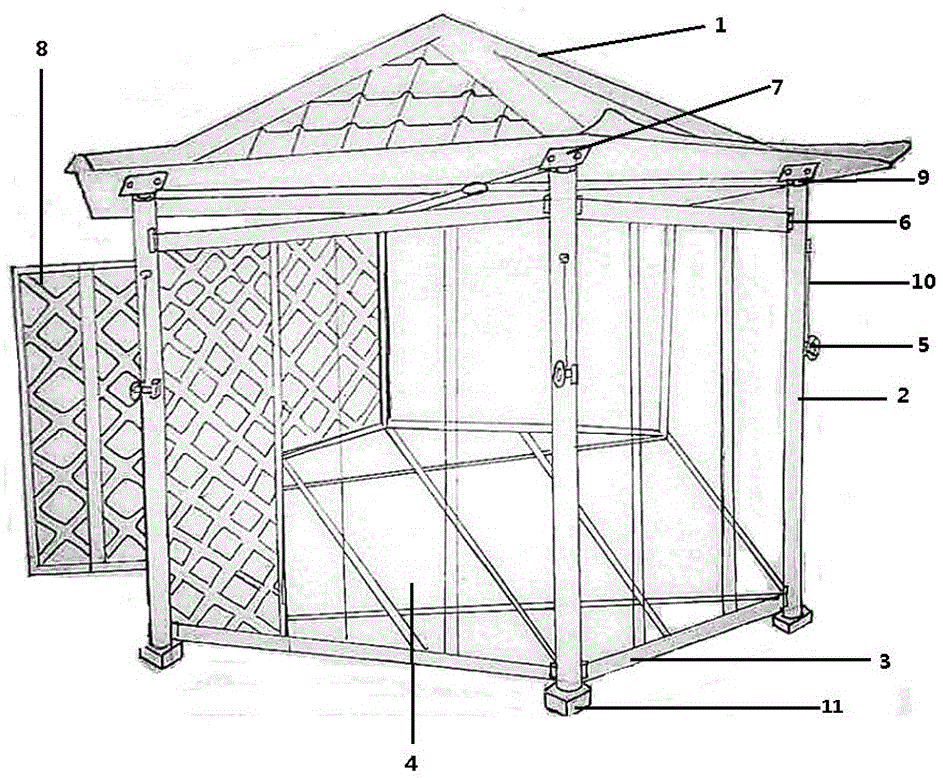

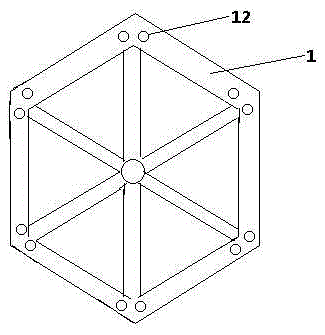

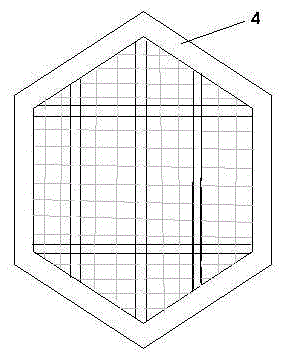

[0020] Embodiment 1: as Figure 1~5 As shown, the grass storage rack described in this embodiment has a grass storage rack base, and the grass storage rack base includes a ceiling structure 1, six support columns 2, six edge protection nets 3, a bottom load-bearing structure 4, and pulleys Lifting screw 5, edge protection mesh slot 6, six support column joints 7, door 8, lift rod 9, steel wire 10, support column load-bearing base 11, six ceiling joints 12 and latch 13; the lift rod 9 They are respectively nested in one end of the six support columns 2, and the joints 7 of the six support columns are respectively fixed on the lifting rods 9; the side walls of the six support columns 2 are all fixedly provided with a pulley lifting screw 5, so The lifting rod 9 is connected to the pulley lifting screw 5 through a steel wire 10; the supporting column load-bearing base 11 is fixedly arranged on the other end of the six supporting columns 2, and one side edge of the bottom load-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com