Linear motor anti-fall protection apparatus

A protection device, linear motor technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as accidents and easy falling of movers, and achieve a simple and flexible structure, fast overall response time, and good application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

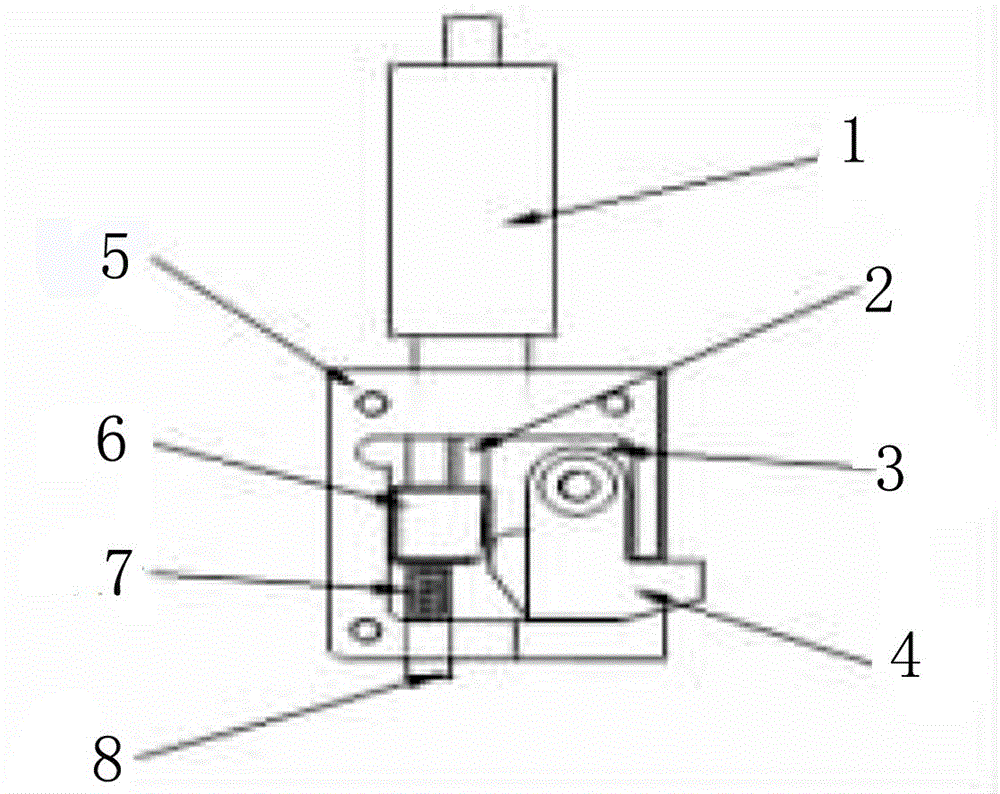

[0014] An anti-drop protection device for a linear motor, comprising a solenoid, an iron core 2, a torsion spring 3, a hook 4, a slider 6, a spring 7, and a pin shaft 8; wherein, the solenoid is connected with the iron core 2; the iron core The slider 6 and the spring 7 are sequentially sleeved on the 2; the iron core 2 and the hook 4 are connected to each other through the torsion spring 3 .

[0015] Wherein, a linear motor drop protection device is further provided with a metal casing 5, the casing 5 is connected to the iron core 2 through a pin 8, and the iron core 2 passes through the casing 5 and extends outward. The solenoid is an electromechanical solenoid 1, which is a cylindrical three-dimensional coil uniformly wound by wires.

[0016] Its working principle is: when the solenoid is not energized, the iron core 2 is in the unextended state, the slider 6 reaches the top of the stroke under the thrust of the spring 7, and the hook 4 is in a circle with the slider 6 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com