Floor system adopting cross-shaped beams

A cross-shaped and cross-shaped technology, which is applied in the field of modular steel structure housing construction, can solve the problems of increasing the shared area, reducing the thickness of components, and complex processing of components, and achieves the effect of accelerating construction efficiency, improving assembly speed, and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

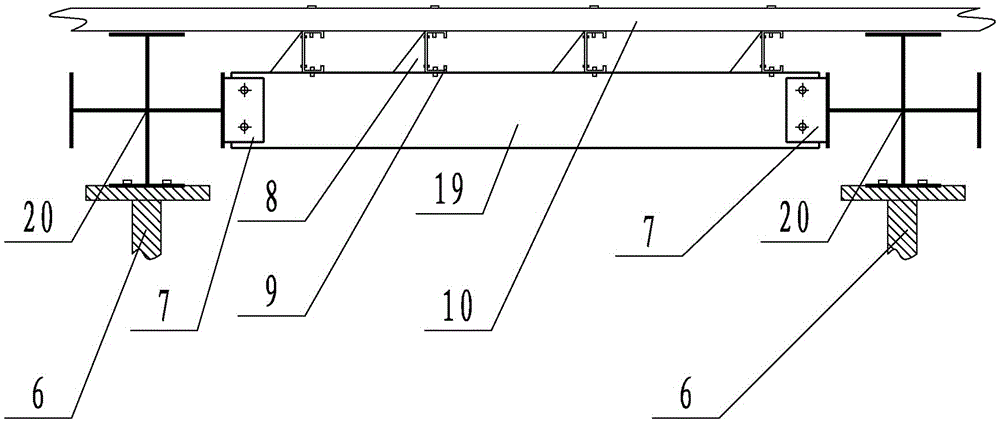

[0019] Such as figure 1 , 2 , 8-10, the floor system of the present invention includes two first cross-shaped steel beams 16 parallel to each other, two second cross-shaped steel beams 17 parallel to each other, and the first cross-shaped steel beams 16 The first cross steel structure beam column 1 between one end and the end of the adjacent second cross steel beam 17, an H-shaped steel beam keel 6 is arranged between the two first cross steel beams 16, two respectively The second cross steel structure beam column 20 arranged on the upper end of the corresponding H-shaped steel beam keel 6, the connecting beam 19 arranged between the two second cross steel structure beam columns 20, the connecting beam 19 arranged on the two second cross steel structure beams The prefabricated decorative panel 10 on the upper end surface of the column 20, the floor C-shaped beam 9 arranged between the lower surface of the prefabricated decorative panel 10 and the upper end of the connecting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com