Lanolin-rubber gloves with skin care effect

A rubber glove and lanolin technology, applied in the field of rubber products, can solve problems such as damage to the user's hand health, cracking, and dry skin, and achieve the effects of preventing pollution, moisturizing and filling the skin, and improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

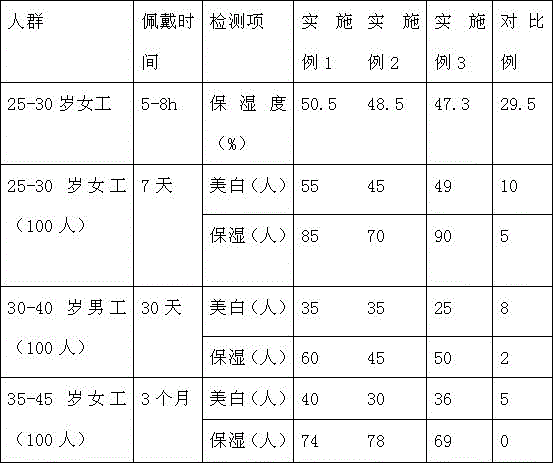

Examples

Embodiment 1

[0050] A preparation method of lanolin rubber gloves with skin care effect, the preparation method is as follows:

[0051] (1) Preparation of rubber material A

[0052] ①Put 55 parts of NR natural rubber, 11 parts of oil-soluble lanolin, and 5 parts of terminal vinyl silicone oil into the reactor by mass parts, control the stirring rate to 120r / min, and the temperature of the reactor at 90°C, and perform a mixing for 15 minutes ;

[0053] ②Put 3 parts of crosslinking agent DCP, 2 parts of vulcanizing agent DTDM and 1 part of accelerator CZ into the reaction kettle after step (1) ① first mixing by mass parts, control the stirring rate to 130r / min, and react The temperature of the kettle is 115°C, and the secondary mixing is carried out for 8 minutes, and then left for 45 minutes for swelling;

[0054] ③Control the temperature of the reaction kettle after step (1)② to 148°C, and the stirring speed is 60r / min, and react for 40min to obtain rubber material A;

[0055] (2) Prepa...

Embodiment 2

[0062] A preparation method of lanolin rubber gloves with skin care effect, the preparation method is as follows:

[0063] (1) Preparation of rubber material A

[0064] ①Put 58 parts of NR natural rubber, 14 parts of oil-soluble lanolin, and 6 parts of vinyl-terminated silicone oil into the reactor by mass parts, control the stirring rate at 140r / min, and the temperature of the reactor at 105°C, and perform a mixing for 15 minutes ;

[0065] ②In parts by mass, put 3 parts of crosslinking agent DCP, 2 parts of vulcanizing agent DTDM and 1 part of accelerator CZ into the reaction kettle after the first mixing in step (1), control the stirring rate to 145r / min, and react The temperature of the kettle is 118°C, and the secondary mixing is carried out for 12 minutes, and then left for 50 minutes for swelling;

[0066] ③Control the temperature of the reaction kettle after step (1)② to 155°C, and the stirring speed is 65r / min, and react for 50min to obtain the rubber material A;

[...

Embodiment 3

[0074] A preparation method of lanolin rubber gloves with skin care effect, the preparation method is as follows:

[0075] (1) Preparation of rubber material A

[0076] ①Put 55 parts of NR natural rubber, 12 parts of oil-soluble lanolin, and 7 parts of vinyl-terminated silicone oil into the reactor by mass parts, control the stirring rate at 140r / min, and the temperature of the reactor at 90°C, and perform a mixing for 14min ;

[0077] ②In parts by mass, put 3 parts of crosslinking agent DCP, 2 parts of vulcanizing agent DTDM and 1 part of accelerator CZ into the reaction kettle after the first mixing in step (1), control the stirring rate to 140r / min, and react The temperature of the kettle is 105°C, and the secondary mixing is carried out for 10 minutes, and then left for 50 minutes for swelling;

[0078] ③Control the temperature of the reaction kettle after step (1)② to 165°C, and the stirring speed is 60r / min, and react for 45min to obtain the rubber material A;

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com