Wood-plastic cable trough cover extrusion die

A cable and extrusion port technology, which is used in the field of extrusion die for wood-plastic cable trunking covers, can solve problems such as breakage, low service life, aging deformation, etc., and achieve long service life, low cost, and good waterproof and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

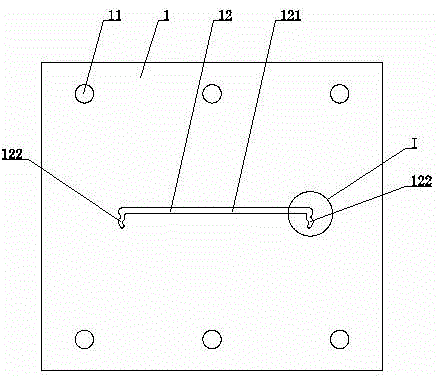

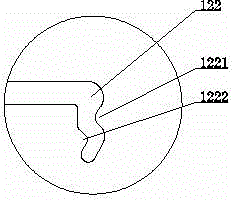

[0008] see Figure 1 to Figure 2 , the present invention includes a die plate 1, the die plate 1 is provided with several circular holes 11, and a die hole 12 is provided in the middle of the die die hole 12, and a horizontal hole 121, and S-shaped holes 122 are symmetrically arranged at two ends of the horizontal hole 121, and a right arc-shaped protrusion 1221 is provided on the right side of the S-shaped hole 122, and a A left arc-shaped protrusion 1222 is provided on the left side of the left side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com