Spray machine rotary nozzle device

A technology of rotating nozzles and sprayers, applied in the direction of spraying devices, etc., can solve problems such as uneven nozzles, slow spraying speed of nozzles, etc., and achieve the effects of reducing spraying time, saving paint, and saving spraying and cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

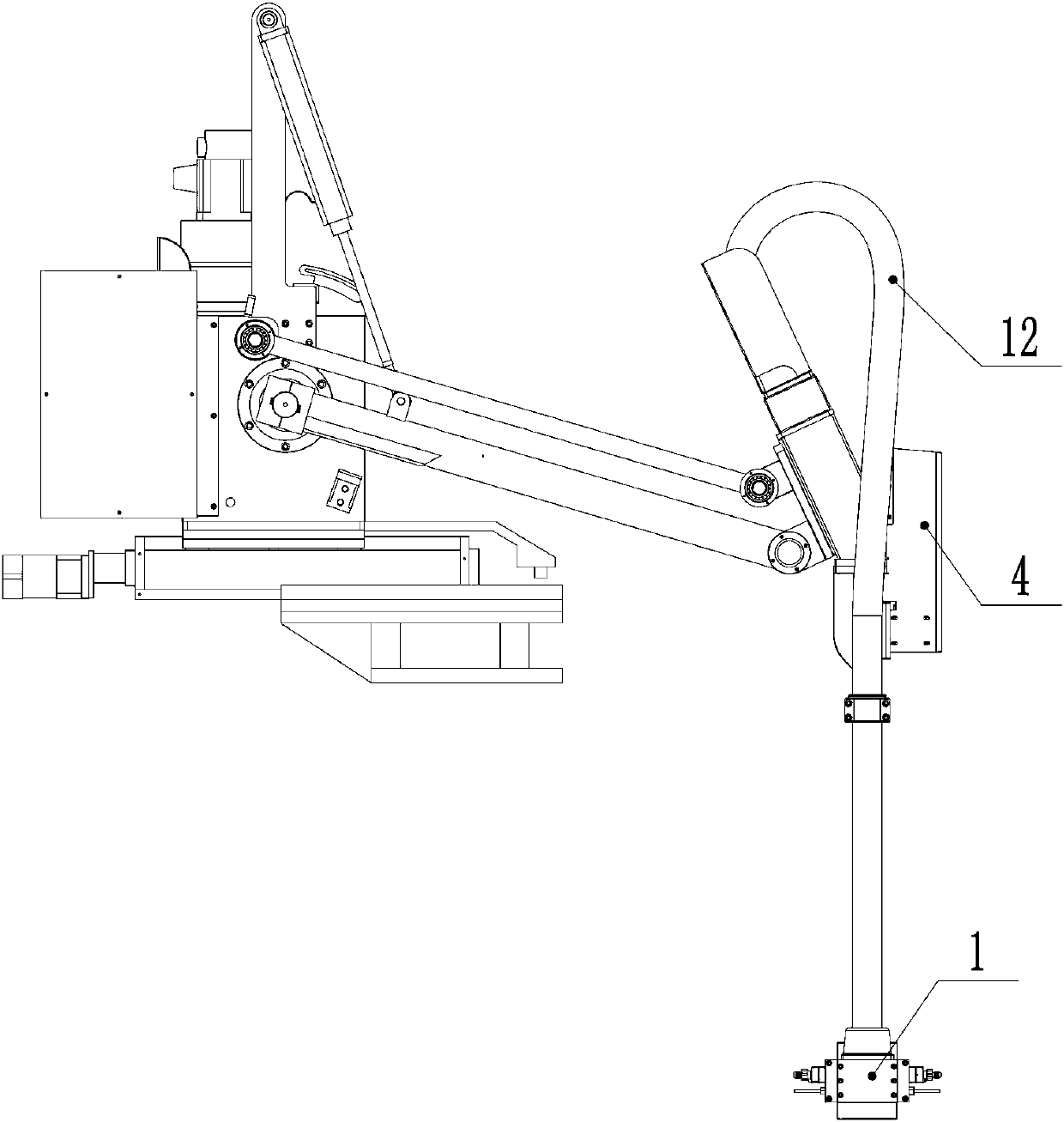

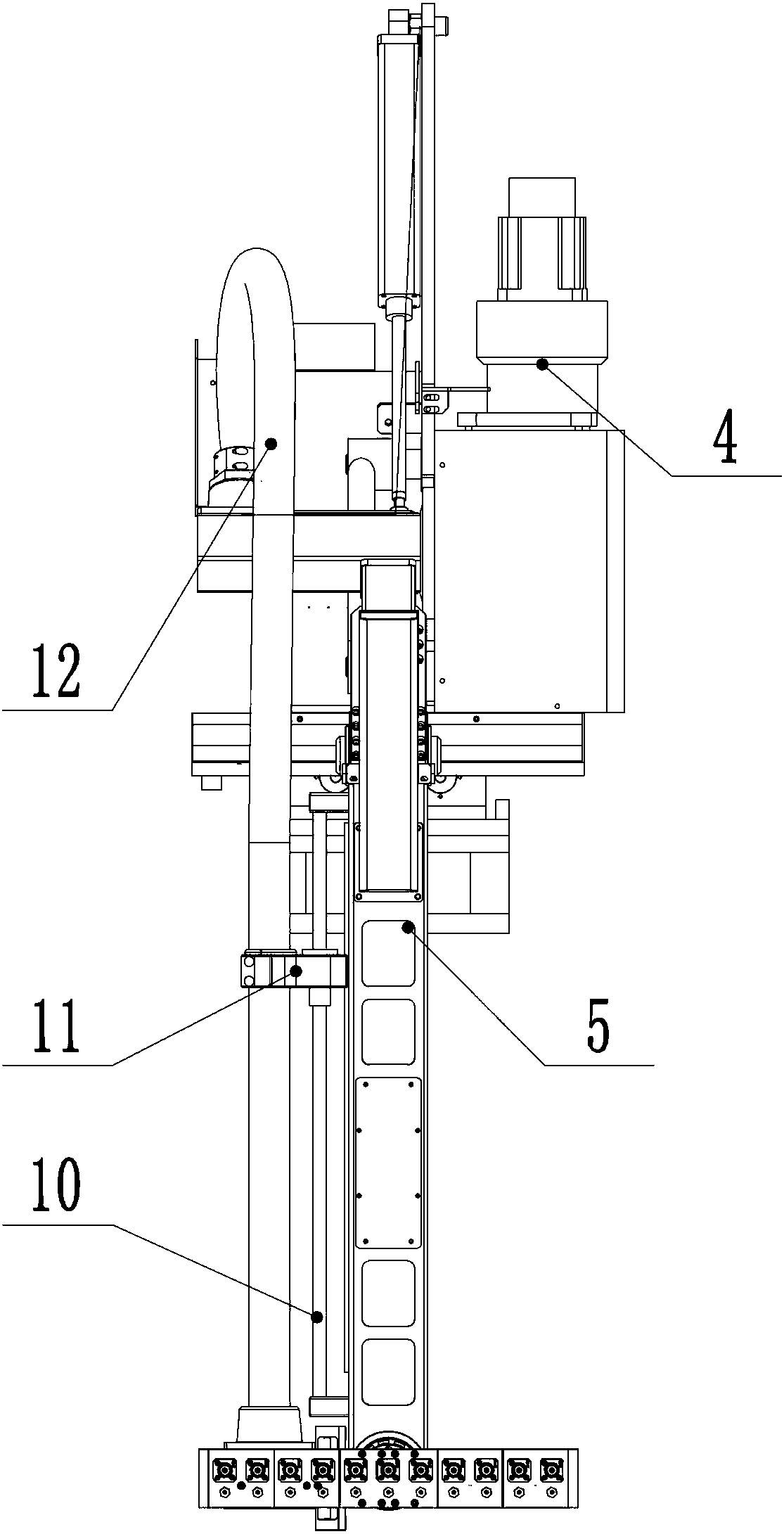

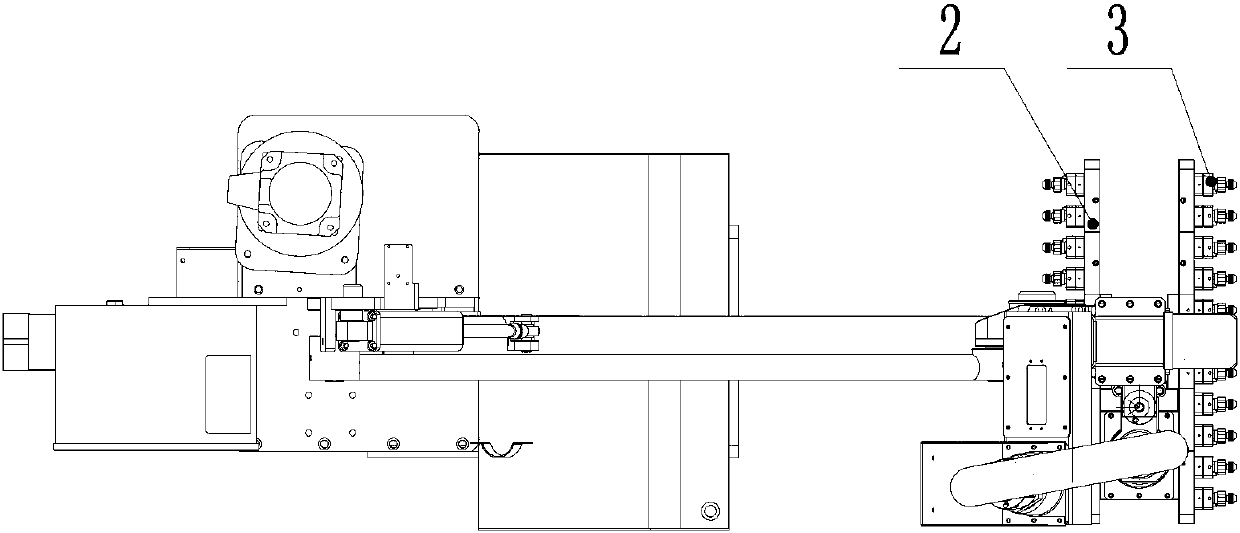

[0021] Please refer to Figure 1-Figure 3 , Figure 7 , figure 1 It is a schematic diagram of a specific embodiment of the sprayer rotary spray head device provided by the present invention.

[0022] The sprayer rotary spray head device includes a rotary spray head main body 1, a nozzle mounting plate 2 is movably installed at both ends of the rotary spray head main body 1, and a plurality of atomizing nozzles 3 are arranged side by side on the nozzle mounting plate 2, and each group of nozzles is electromagnetically controlled. Open and close and the opening and closing of air and water. The main body of the rotary spray head 1 is connected with a power mechanism 4, and the power mechanism 4 drives the main body of the rotary spray head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com