A method for manufacturing a reflective surface of an electrostatically formed film

A production method, electrostatic forming technology, applied in the direction of electrical components, antennas, etc., can solve the problems of few, no specific and detailed production process of the reflective surface, etc., and achieve the effect of simple operation, reliable experience, and control of splicing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

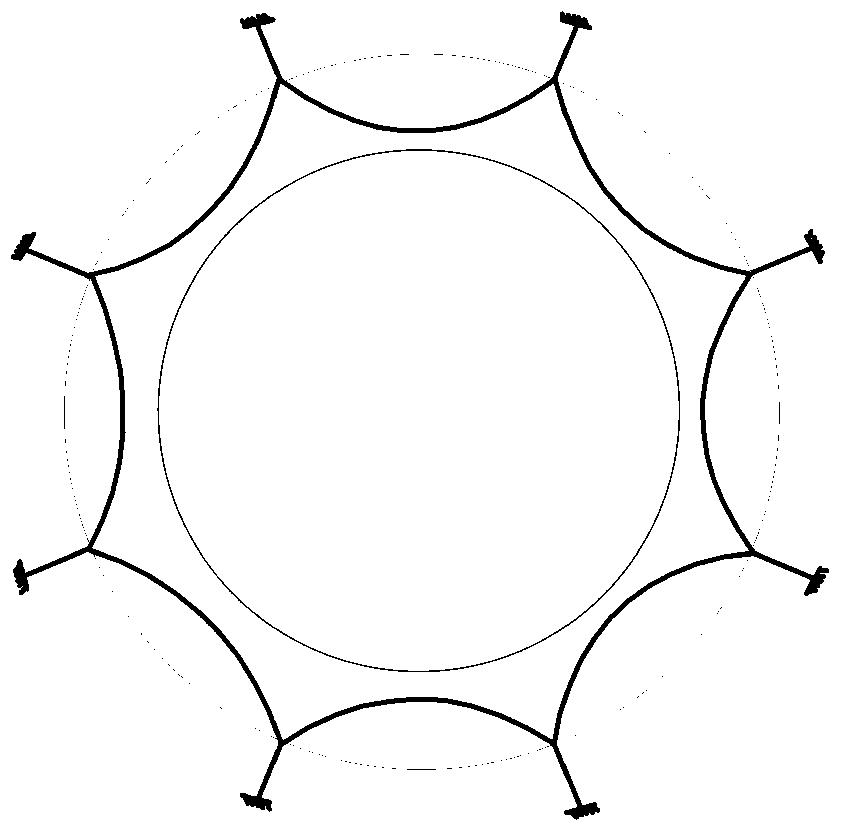

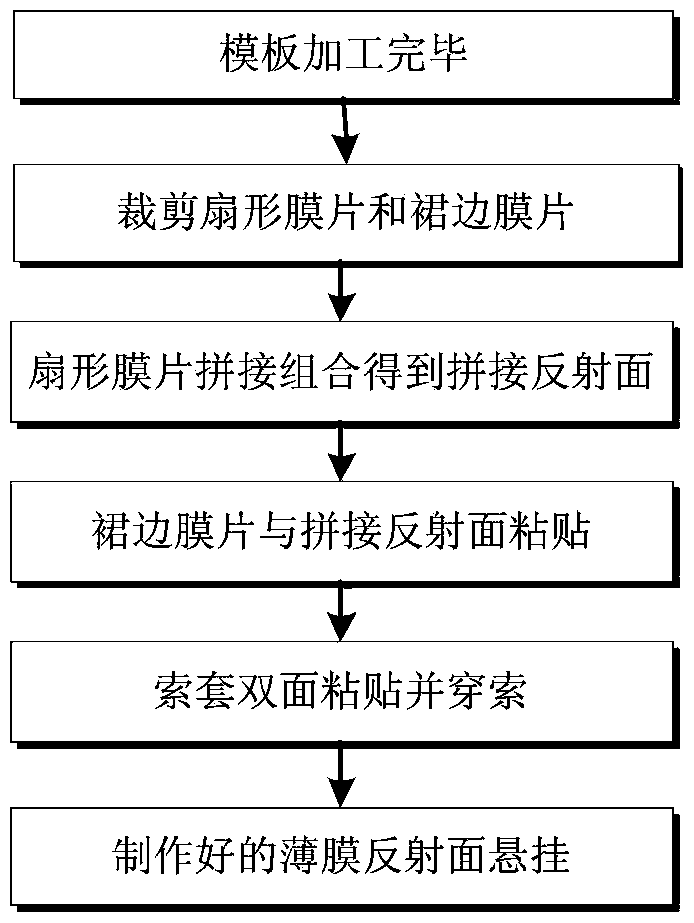

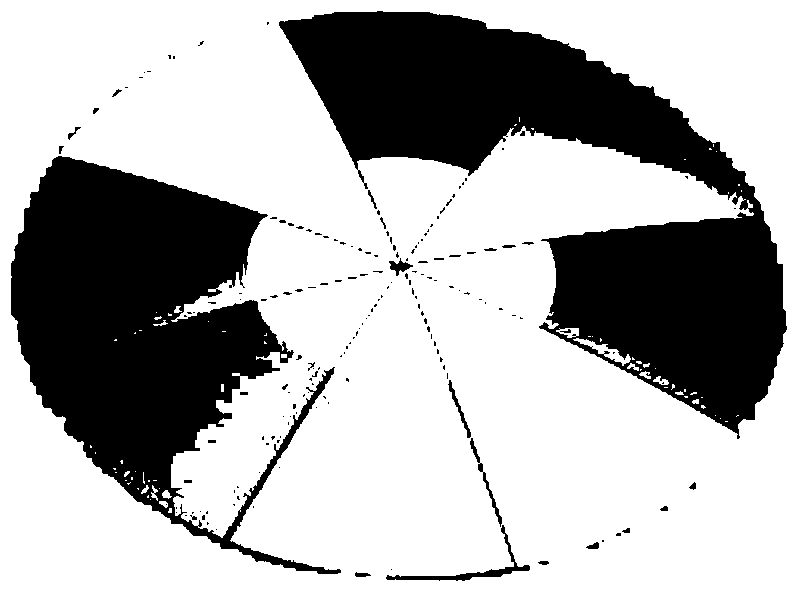

[0038] The invention provides a method for manufacturing the reflective surface of an electrostatically formed film. The basic ideas of the invention are as follows: firstly, after the cutting template and the splicing template are processed, the fan-shaped diaphragm and the skirt diaphragm are cut out by using the cutting template, and placed on the splicing template Paste and combine the fan-shaped diaphragms to obtain a spliced reflective surface, use an adhesive to paste the skirt diaphragm and the spliced reflective surface, paste the cable sleeve on both sides and thread the cable, and finally hang the finished film reflective surface.

[0039] see figure 2 , the specific implementation steps of the present invention include as follows:

[0040] Step 101: Make and process the diaphragm cutting template, skirt cutting template and splicing mold, such as image 3 , Figure 4 as well as Figure 5 shown.

[0041] Step 102 : using the diaphragm cutting template to cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com