Engine system having coolant control valve

一种发动机系统、冷却液的技术,应用在冷却剂流量的控制、发动机元件、发动机的冷却等方向,能够解决冷却液控制阀耐久性变差、不利高温冷却液空化、复杂冷却系统结构等问题,达到有利于空化、提高阀耐久性、简单冷却系统结构的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

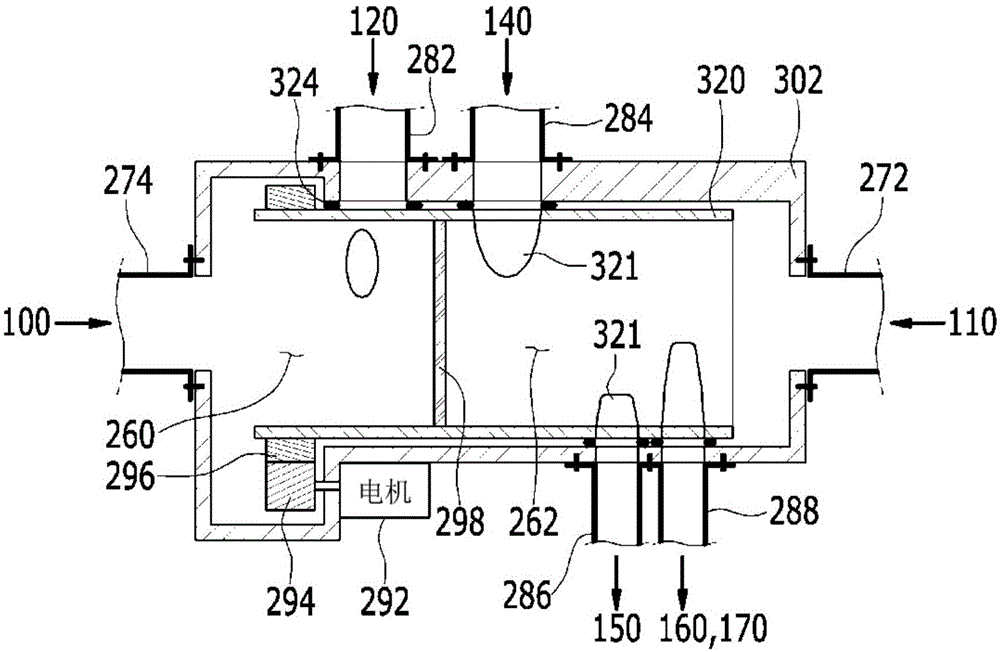

[0032] Reference will now be made in detail to various embodiments of the invention, examples of which are illustrated in the accompanying drawings and described below. While the invention will be described in conjunction with exemplary embodiments, it will be understood that present description is not intended to limit the invention to those exemplary embodiments. On the contrary, the invention is intended to cover not only the exemplary embodiments but also various alternatives, modifications, equivalents and other alternatives, modifications, equivalents and others, which may be included within the spirit and scope of the invention as defined by the appended claims. implementation plan.

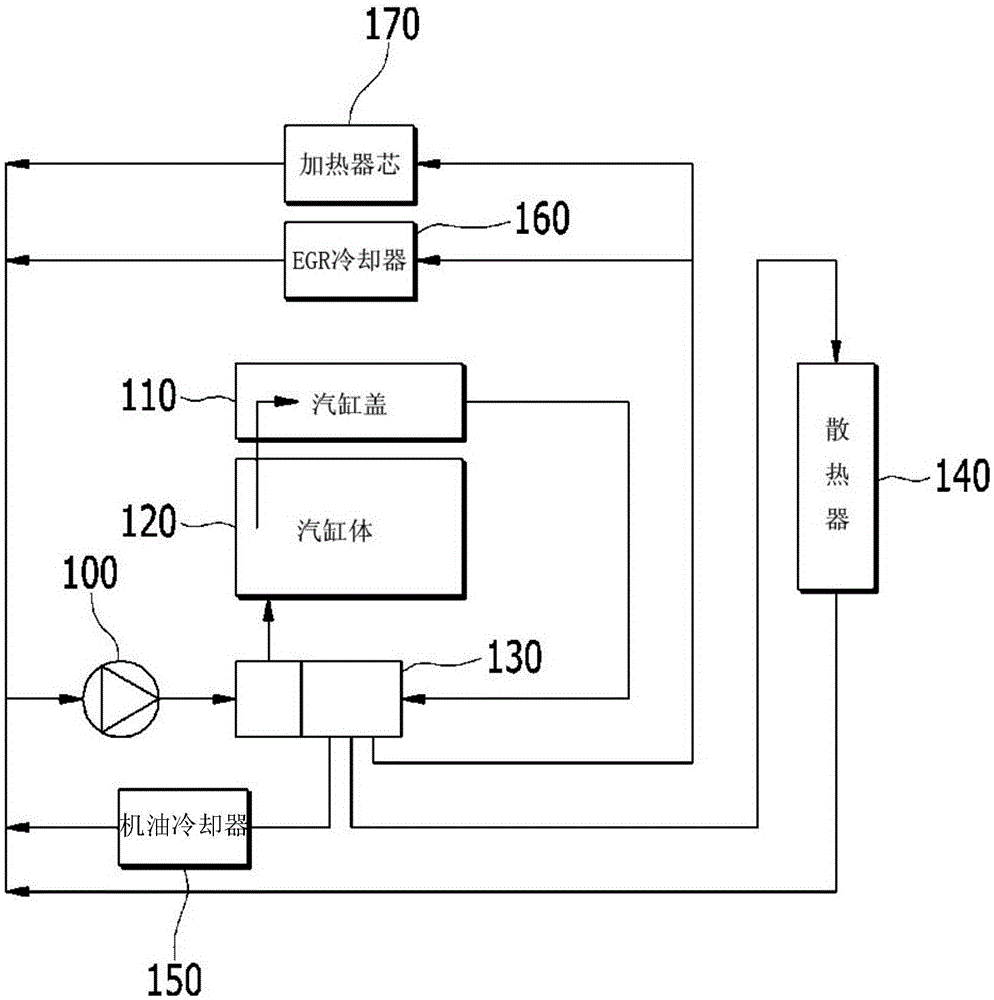

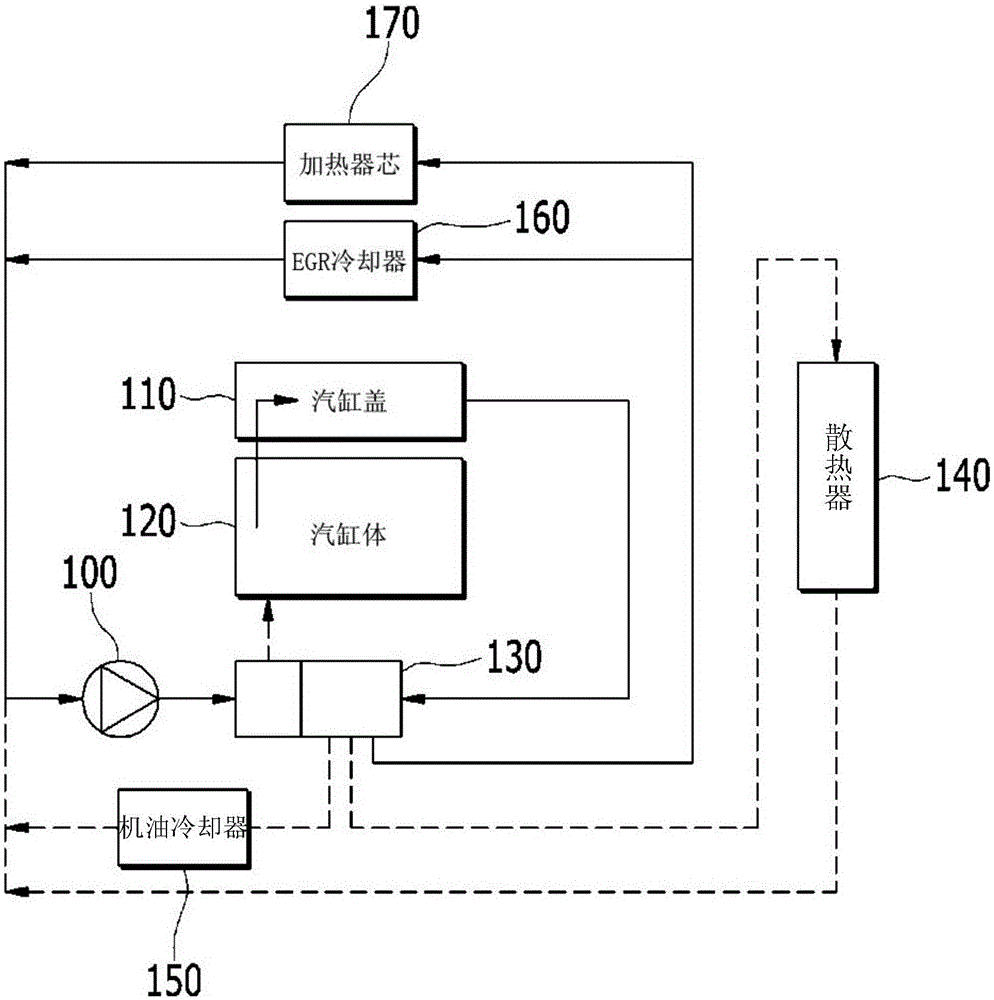

[0033] figure 1 is a flowchart showing the overall flow of coolant in an engine system having a coolant control valve according to various embodiments of the present invention.

[0034] refer to figure 1 , the engine system includes a cylinder head 110 , a cylinder block 120 , a coola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com