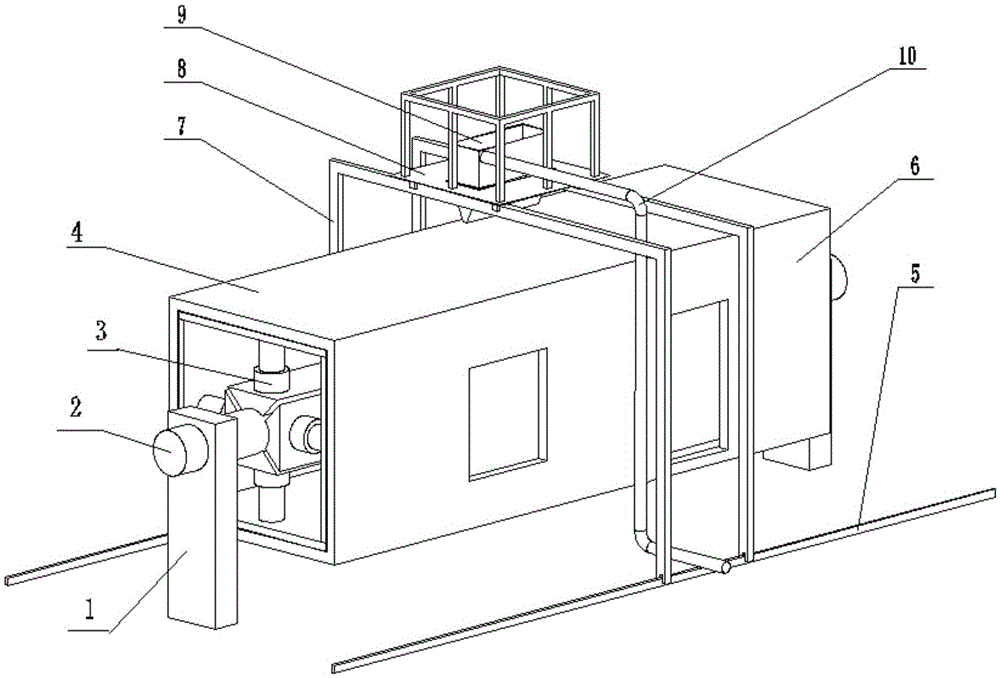

House unit made in integral-forming mode

A house-integrated technology, applied in the field of integral molding of house units, can solve the problems of high construction cost, many connection nodes, uneven quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of one-time molding preparation of housing units

[0035] Step 1, preparing a frame mold driven by a driving device that can rotate longitudinally and / or laterally along the mold and whose longitudinal and / or lateral size can be adjusted;

[0036] Step 2, preparing the barrel dragon skeleton;

[0037] Step 3, prepare the inner wall layer mortar:

[0038] Using water, white cement, quartz sand or river sand, waterproof curing agent, reinforcing agent, flexibilizer and / or surface coloring agent as raw materials, prepare inner body layer mortar by known method;

[0039] Step 4, prepare middle layer mortar; Prepare with following raw material according to known method:

[0040] Water, ordinary Portland cement or rapid hardening aluminum sulfate cement as binder, quartz sand or river sand as aggregate, alkali-resistant fiber yarn, alkali-resistant fiber felt and / or nylon crack-resistant fiber as fiber material, Waterproof curing agent, strengthening agent, sof...

Embodiment 2

[0052] A building unit with a furry surface effect on the outer wall is prepared by one-shot molding.

[0053] Other methods are the same as in Example 1 except for the spray printing with integrated molding of the interior and exterior or the preparation of a mortar with a woolen surface effect.

Embodiment 3

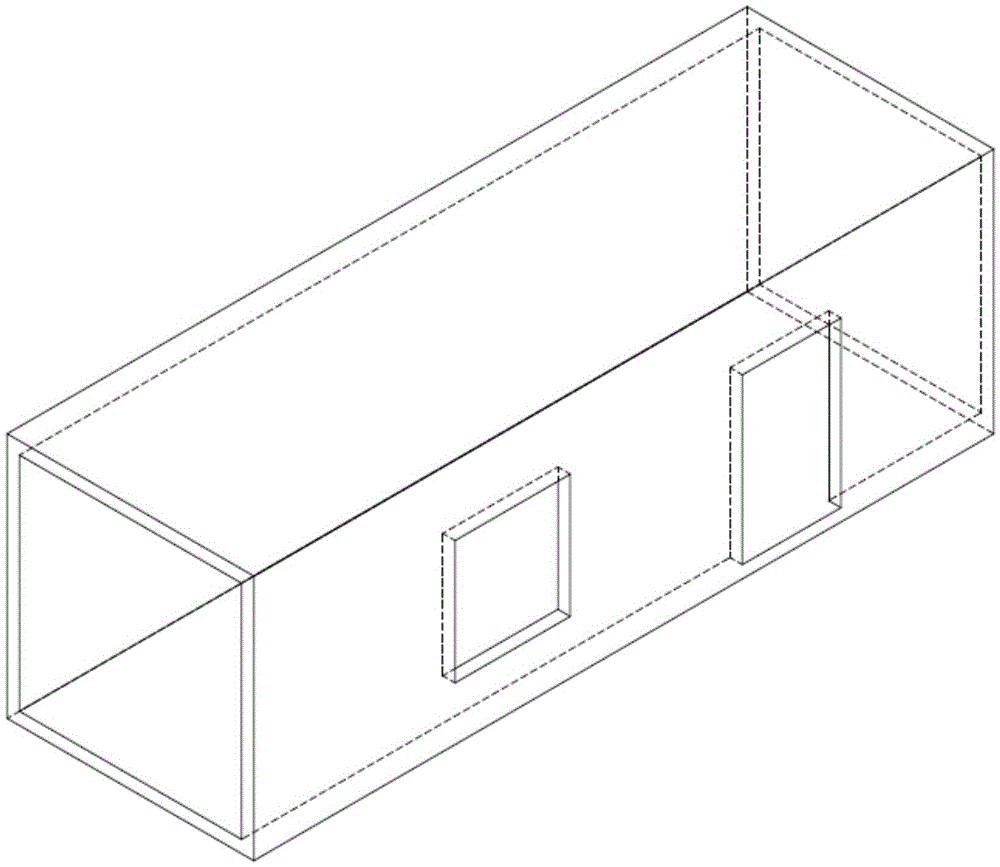

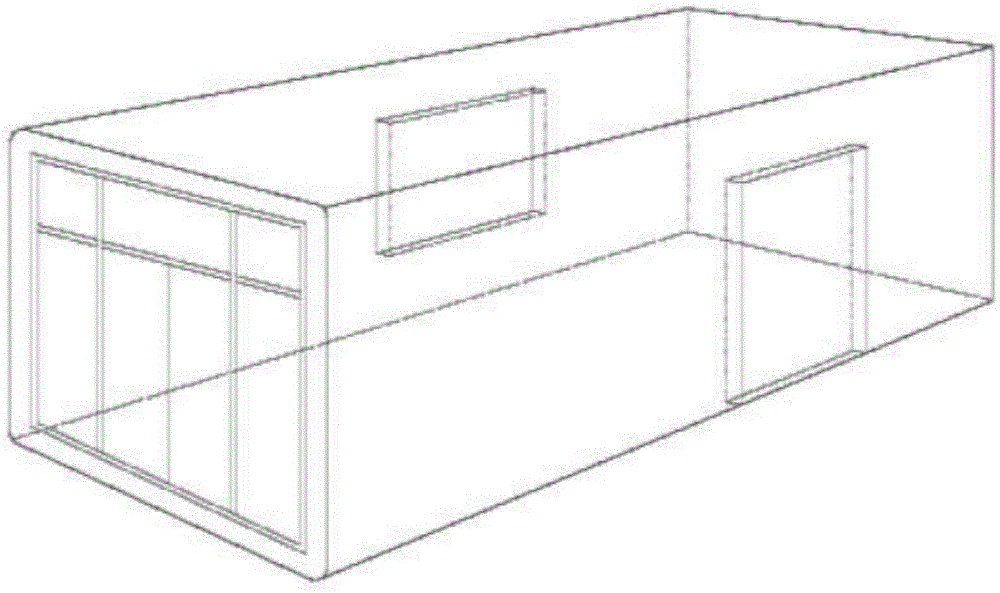

[0055] One-piece preparation of housing units with window frames, such as figure 2 as shown,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com