Coal-leveling device and coal-leveling method

A technology of leveling coal and leveling coal holes, which is applied to the field of leveling coal devices on the top of large Kong coal blending bunkers, can solve the problems of increased land occupation and infrastructure costs, increased cost of material distribution equipment, and increased construction and installation costs of the project, so as to save engineering construction and installation The effect of cost, simple structure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

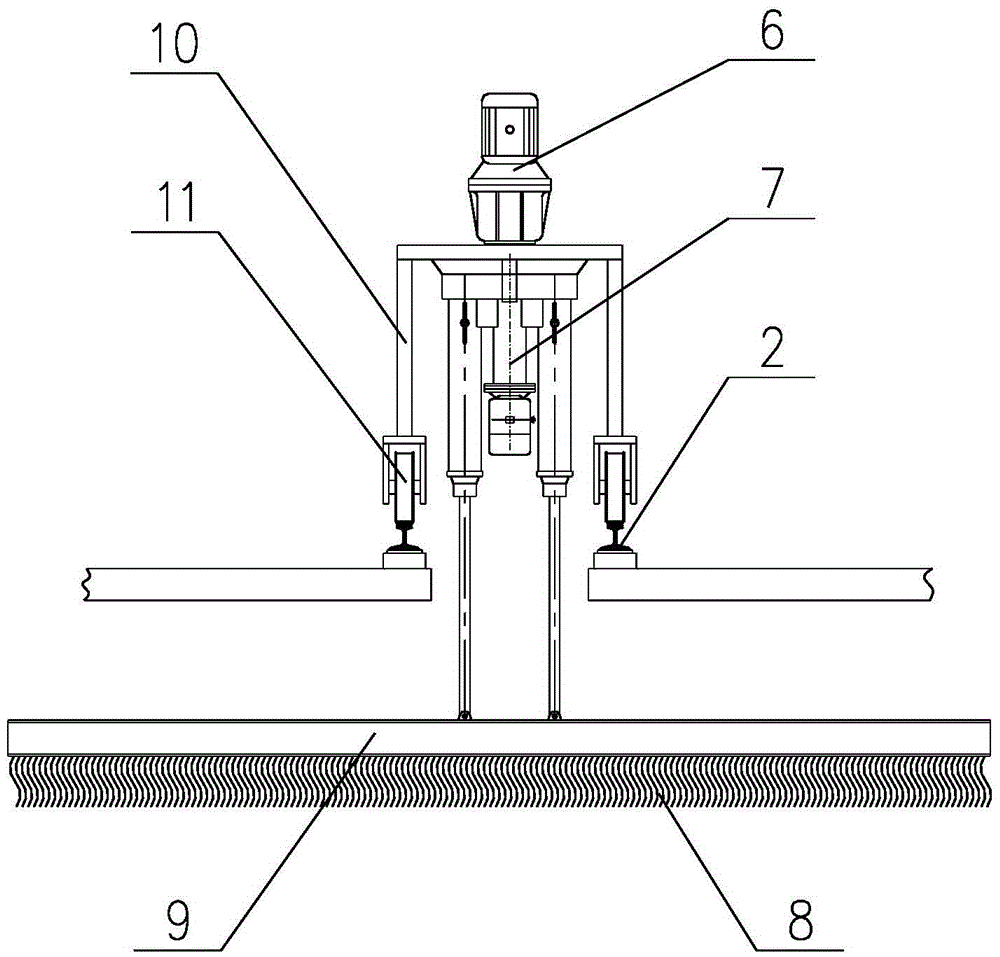

[0027] See Figure 2-Figure 3 , is the structural schematic diagram of the flat coal device of the present invention. The coal leveling device of the present invention includes a coal leveling device trolley arranged on the running track of the trolley on the top of the coal bunker, and the coal leveling device trolley is composed of a trolley frame and a running mechanism fixed on the trolley frame, an electro-hydraulic motor It is composed of single-cylinder double push rod, gear motor and leveling coal mechanism; the trolley of the leveling coal device moves reversibly along the running track of the trolley under the driving of the running mechanism, and the top of the coal bunker between the double-row tracks of the running track of the trolley is provided with a leveling coal hole; the gear motor is located in the small On the frame, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com