Mobile Bulk Material Unloader

A mobile, unloading machine technology, applied in the direction of loading/unloading, transportation and packaging, etc., can solve the problems of high cost, inability to excavate foundation pits in the factory area, waste, etc., and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

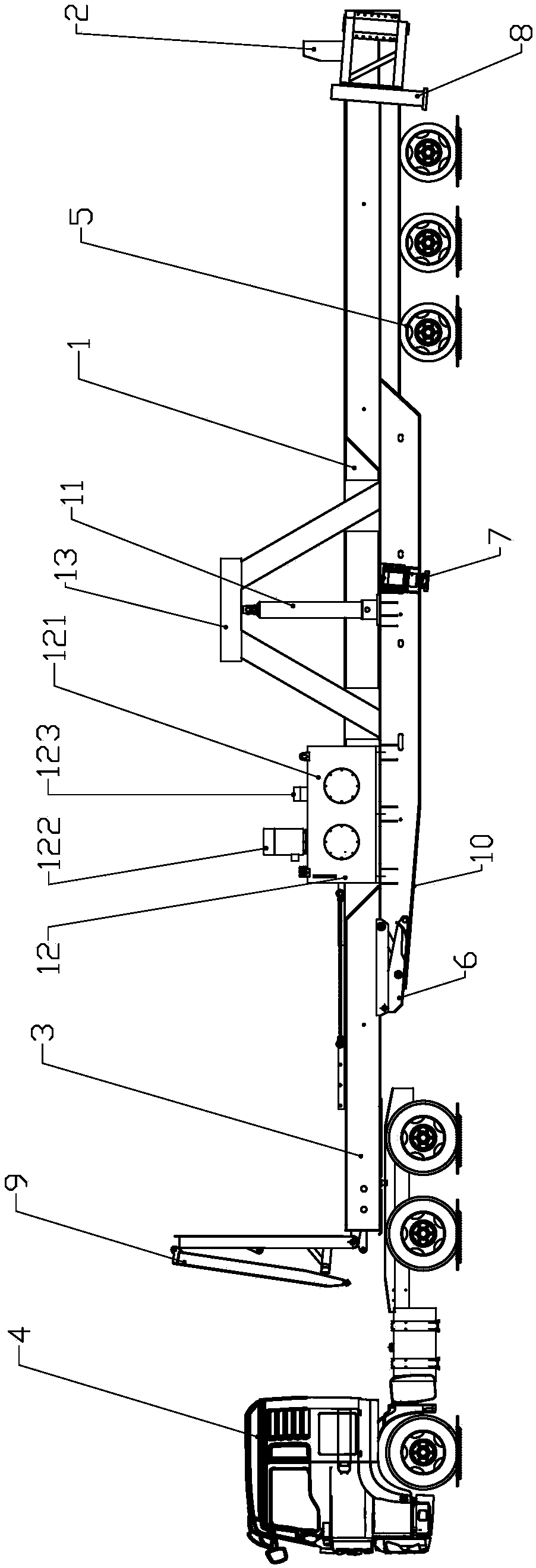

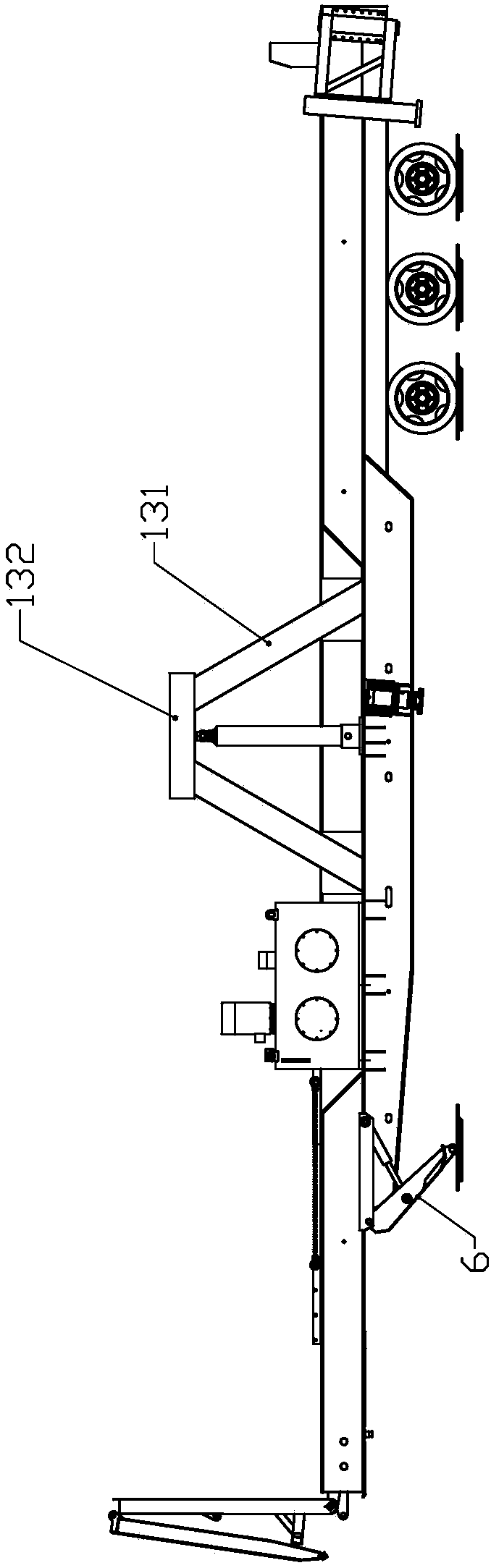

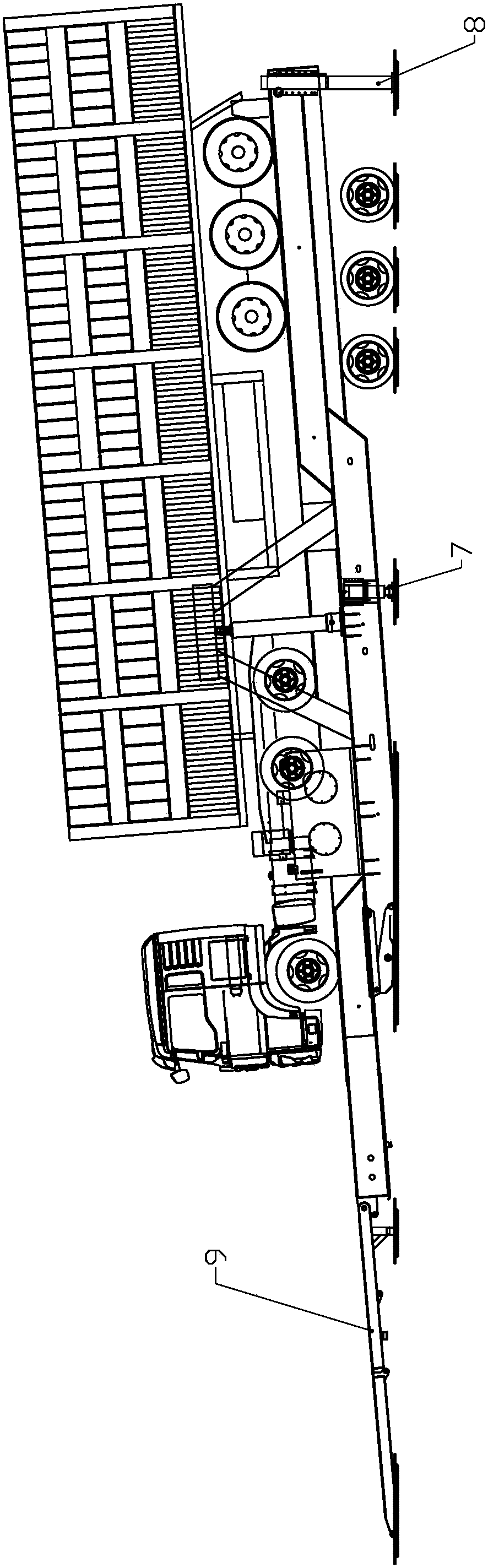

[0034] Refer to the attached figure 1 to attach Figure 11 The mobile bulk material unloader of the present invention will be described in detail below.

[0035] The mobile bulk material unloading machine of the present invention has a structure comprising an overturning platform 1, and a wheel stopper 2 is arranged at the rear of the overturning platform 1. It is hinged with the special semi-trailer chassis 3, the front part of the special semi-trailer chassis 3 is connected with the tractor 4, the rear side lower part of the special semi-trailer chassis 3 is provided with a moving wheel 5, and the special semi-trailer chassis 3 Front outriggers 6 are arranged on the left and right sides of the front end, middle outriggers 7 are arranged on the left and right sides of the middle part, rear outriggers 8 are arranged on the left and right sides of the rear end, and a folding ladder 9 is arranged on the front part of the special semi-trailer chassis 3 , the bottom front side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com