A brick clamping and stacking device

A palletizing device and grabbing device technology, which is applied in transportation and packaging, object depalletizing, object stacking, etc., can solve the problems of high brick price and high manufacturing cost, and achieve the goal of improving work efficiency and controlling labor costs spending, the effect of achieving precise targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

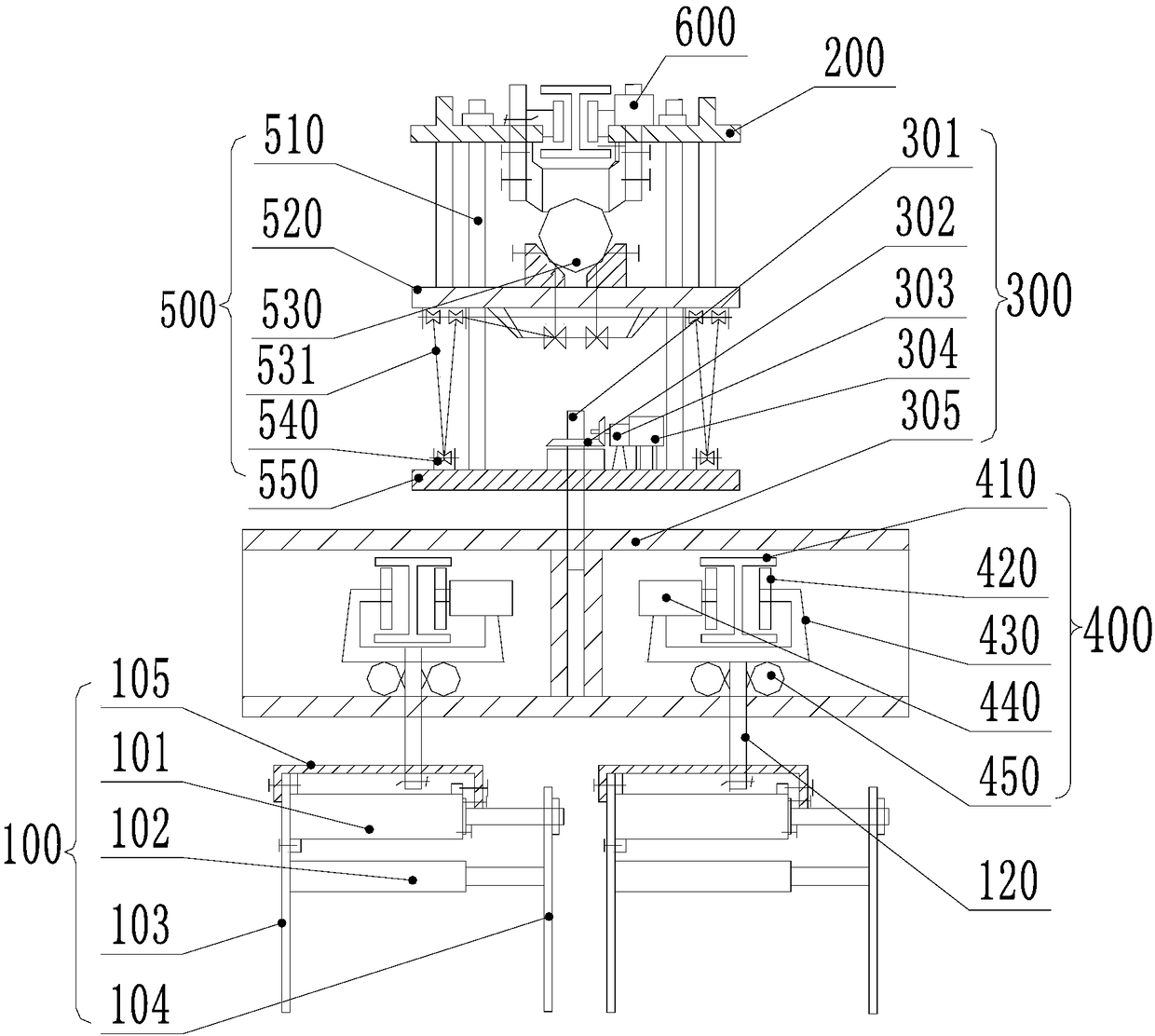

[0056] see Figure 1 to Figure 6 , Embodiment 1 of the present invention provides a brick clamping and stacking device, which mainly includes a grabbing device 100, a lifting device 500, a frame body 200 and a position adjusting device.

[0057] The grabbing device 100 is used to clamp bricks, and the position adjusting device is used to adjust the real-time position of the grabbing device 100. The position adjusting device is connected to the frame body 200 through the lifting device 500, and the grabbing device 100 is connected to the position adjusting device.

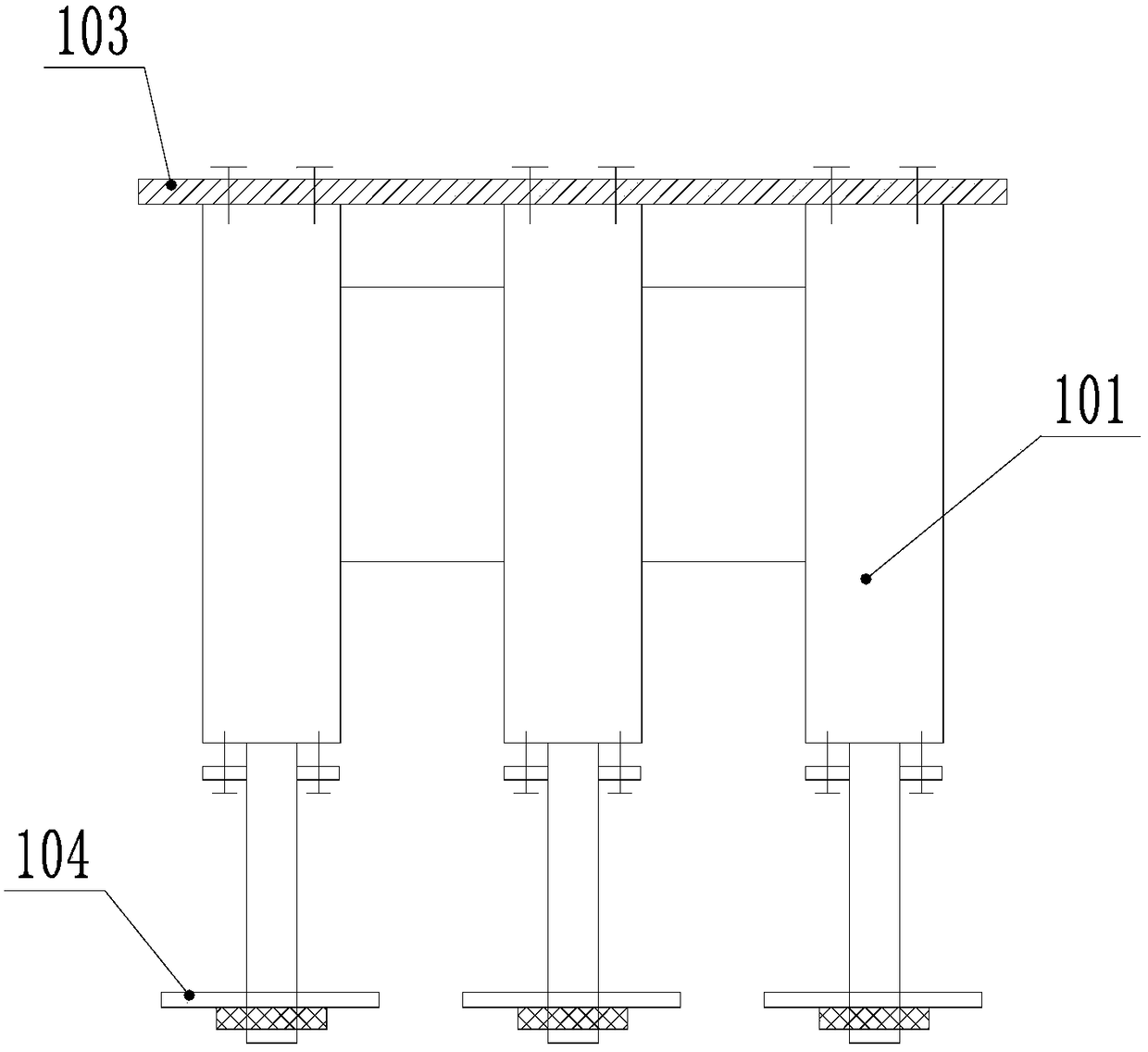

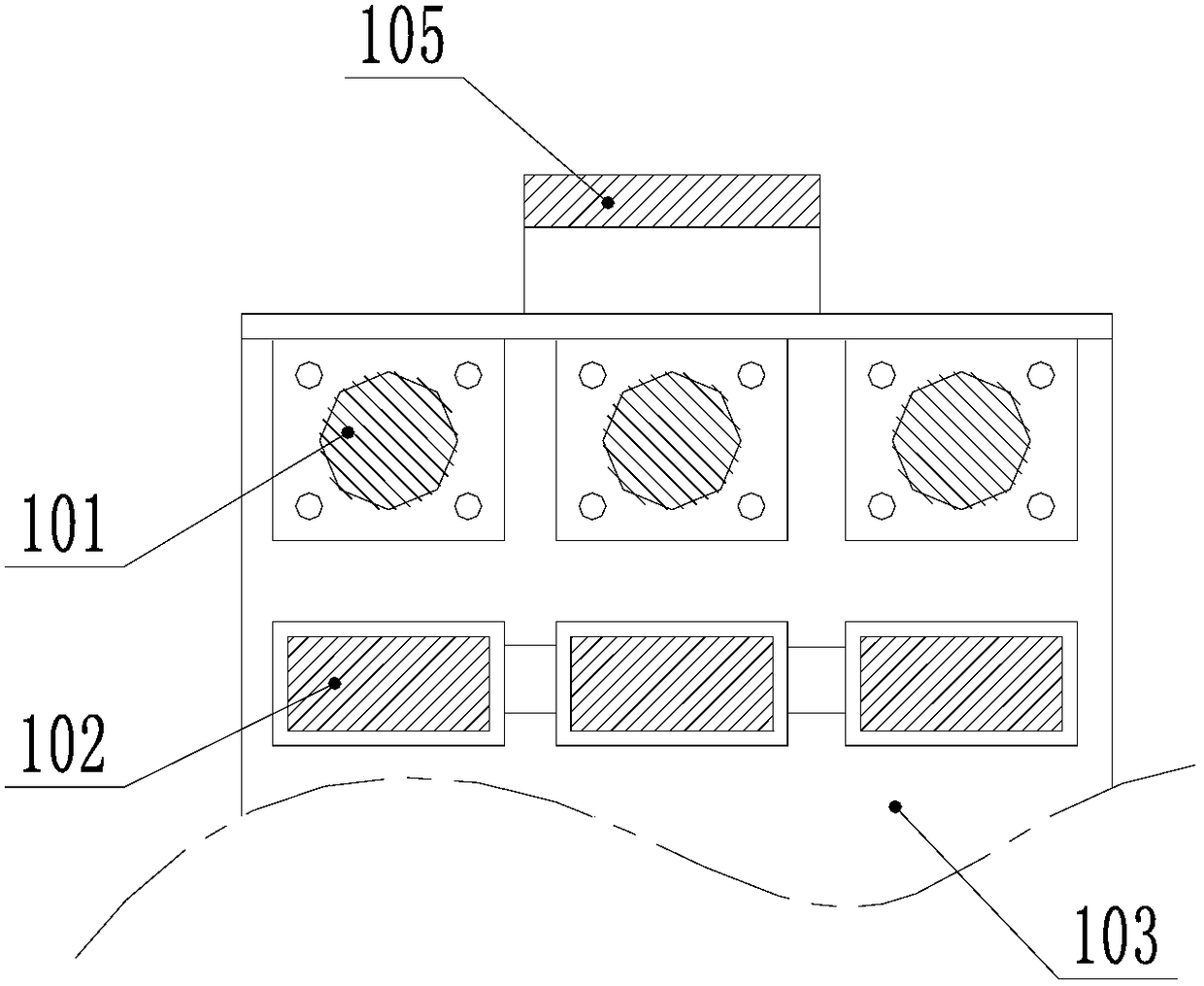

[0058] see figure 1 , figure 2 and image 3 , in this embodiment, the grabbing device 100 includes a telescopic assembly, a first limiting member 103 and a second limiting member 104, and the first limiting member 103 and the second limiting member 104 are respectively fixed on both sides of the telescopic assembly , the telescopic assembly is used to change the distance between the first limiting member 103 and...

Embodiment 2

[0080] see Figure 7 and Figure 8 , Embodiment 2 of the present invention provides a brick clamping and stacking device. The main difference between the second embodiment and the first embodiment is that in the embodiment, the grabbing device includes a brick clamp frame 114, a telescopic cylinder 111, an extension rod 113 and a control member 117, and the brick clamp frame 114 includes a limit plate 112, and the telescopic The cylinder body of the cylinder 111 is fixedly connected with the brick clamp frame 114, the control part 117 is connected with the brick clamp frame 114 in rotation, and the control part 117 is divided into a first section 115 and a second section 116 at the joint between the control part 117 and the brick clamp frame 114 , one end of the extension rod 113 is connected to the piston end of the telescopic cylinder 111, the other end of the extension rod 113 is connected to the first section 115 through the ring buckle 118, and the second section 116 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com