Large diameter spiral pipe winding machine

A spiral pipe and winding machine technology, applied in the field of large-diameter spiral pipe manufacturing equipment, can solve the problems of increased out-of-roundness of the pipe, easy deformation of the guide block, and inconvenient and quick installation holes for radially adjustable rollers. It is not easy to achieve Loose deformation, reduce the effect of out of roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

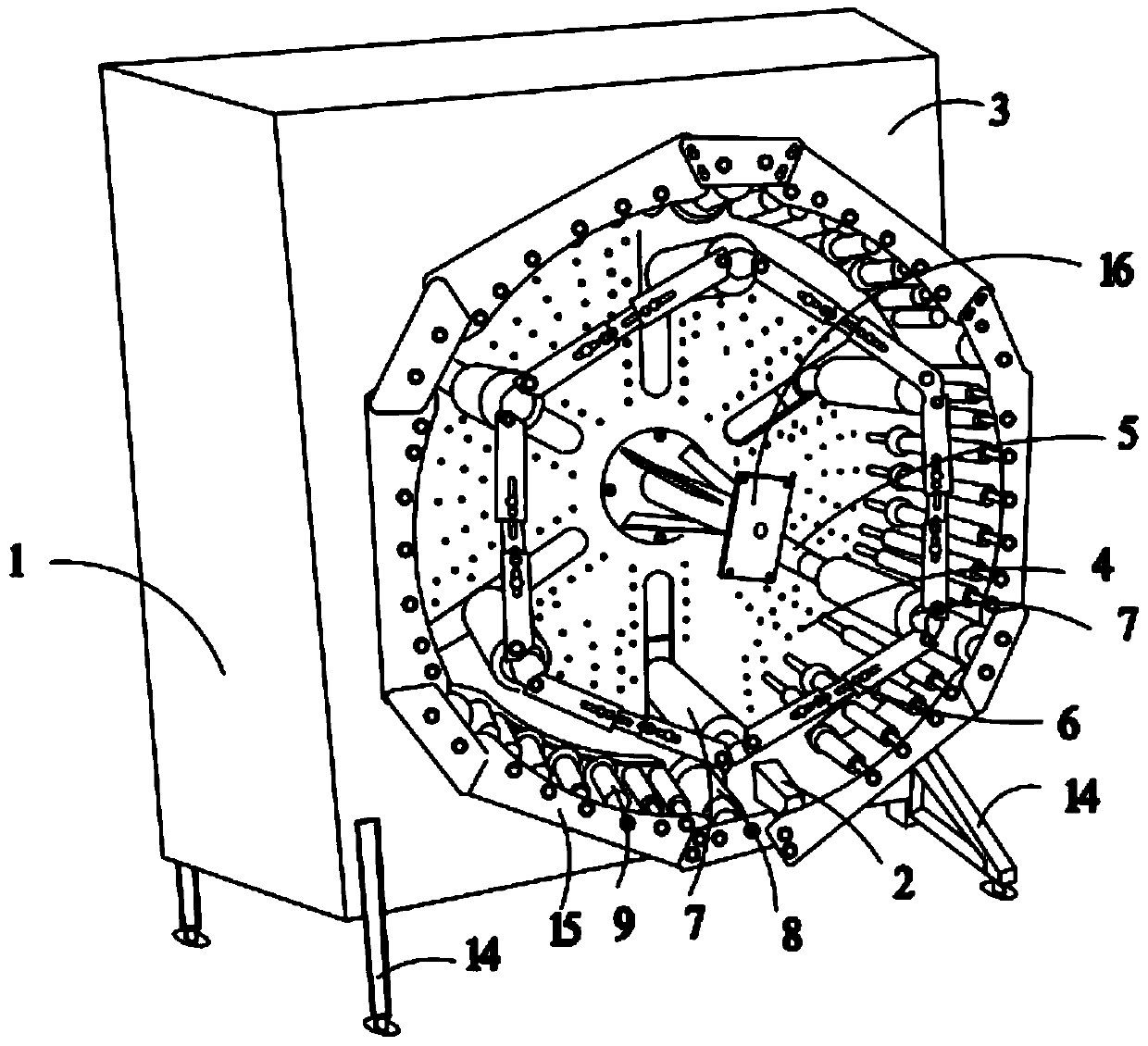

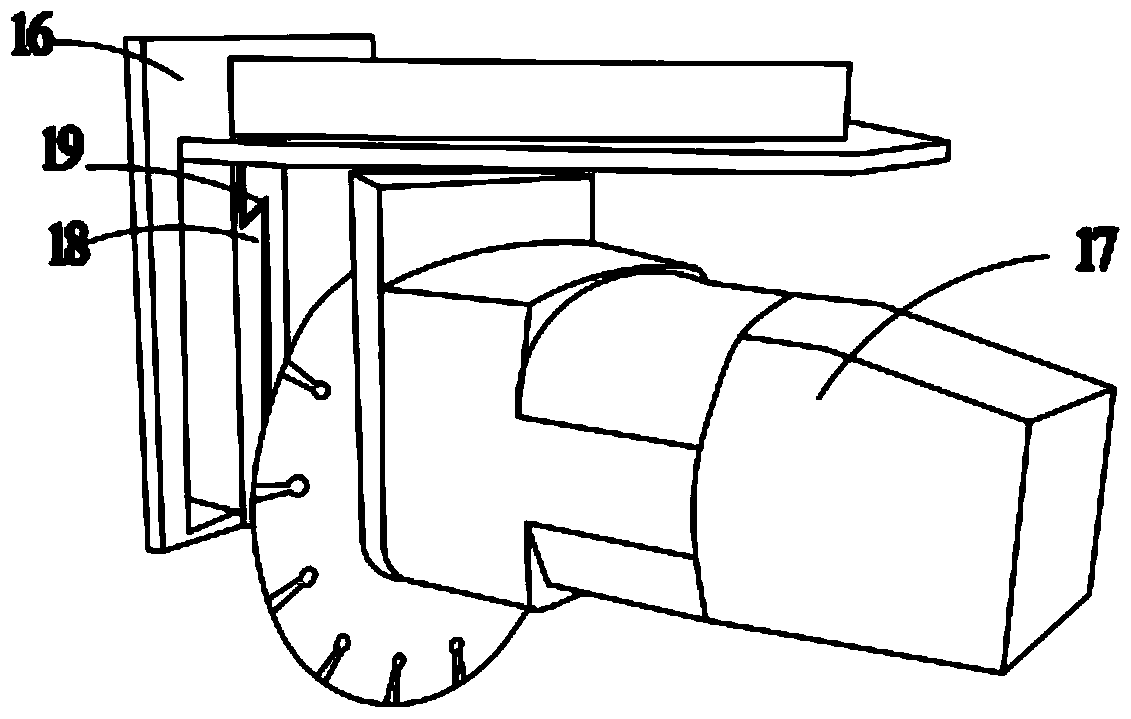

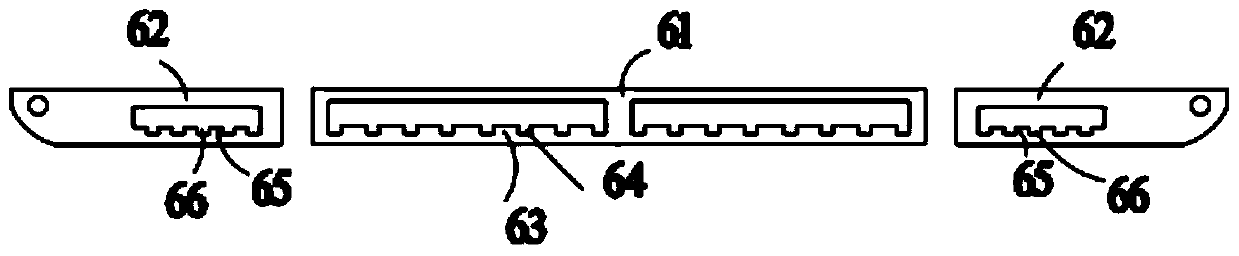

[0018] 1 is the frame, 2 is the feed port, 3 is the main panel, 4 is the round hole, 5 is the strip hole, 6 is the telescopic adjustment rod, 7 is the guide pinch roller, 8 is the limit pinch roller, 9 61 is the middle plate, 62 is the connecting plate, 63 is the first boss, 64 is the first limiting groove, 65 is the second boss, 66 is the second limiting groove, 10 is the chain, 11 is a positioning block, 12 is a strip sliding groove, 13 is a tension wheel, 14 is a support leg, 15 is a fixed plate, 16 is a support frame, 17 is a cutting motor, 18 is a dovetail protrusion, and 19 is a dovetail concave groove

[0019] Depend on figure 1 It can be seen that the large-diameter spiral pipe winding machine includes a frame 1, a feed port 2 arranged on the frame 1, a guiding and pressing mechanism, a pipe diameter limit adjusting mechanism, a transmission mechanism and a cutting mechanism. The frame 1 includes a main panel 3, the feed inlet 2 is arranged at the bottom of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com