A door frame automatic forming machine of different specifications

An automatic forming machine and door frame technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low work efficiency, complicated process, high production cost of door frames, etc., and achieve the effect of novel and unique structure composition and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

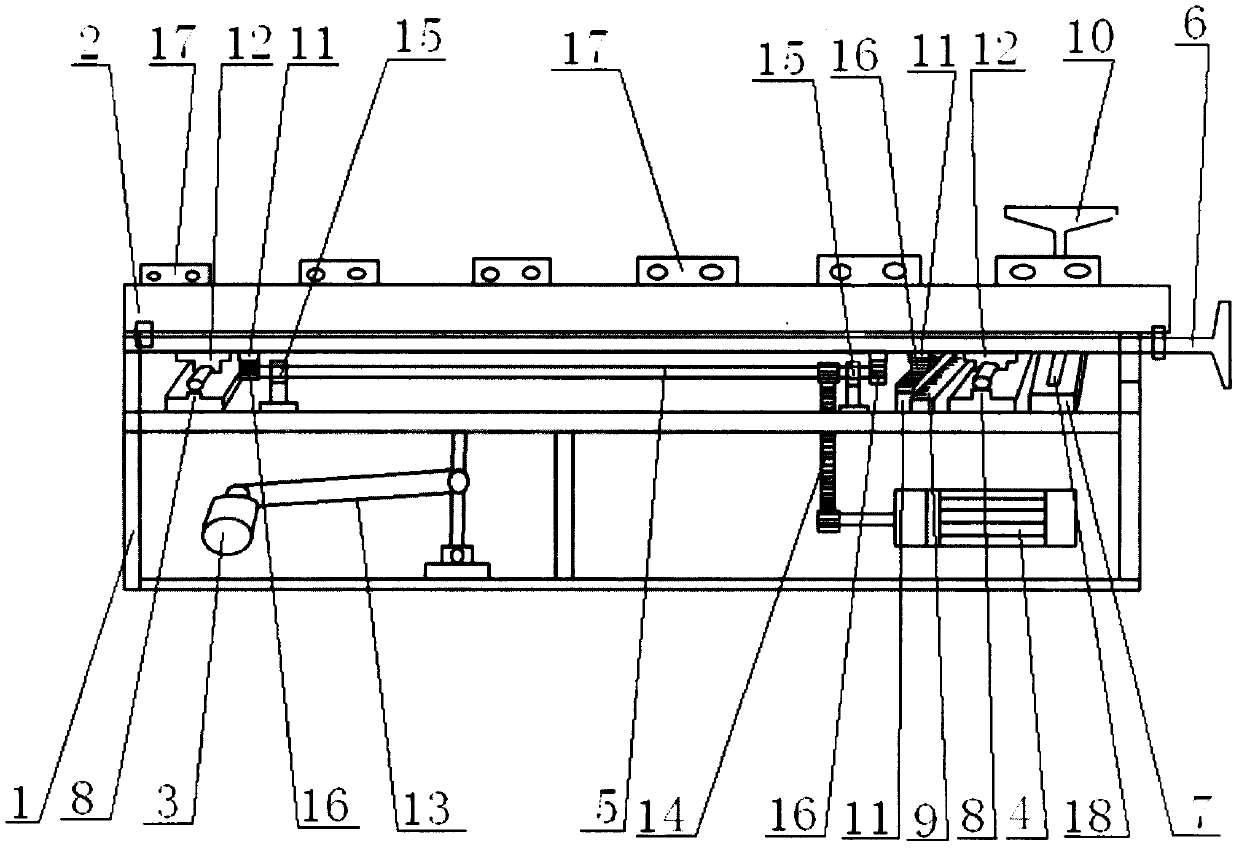

[0016] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0017] The present invention is composed of a frame 1, a door frame movable forming roller device 2, a forming roller power motor 3, a traveling motor 4, a rotating shaft 5, a locking joystick 6, a positioning locking frame 7, a precision guide shaft 8, a scale 9, Locking wrench 10, gear slide rail 11, guide shaft track 12, chain one 13, chain two 14, bearing block 15, gear 16 form.

[0018] figure 1 Shown is the structural representation of the present invention. Wherein, wherein, the frame 1 is a square three-dimensional frame; several door frame fastening frames 17 are arranged on the movable forming roller device 2 of the door frame; the forming roller power motor 3 is an AC motor; the traveling motor 4 is an AC motor The rotating shaft 5 is a cylindrical solid rod body; the locking joystick 6 is made up of a cylindrical solid rod body and a rotating disk; a guide groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com