A drying method for changing the appearance characteristics and flavor of raisins

A technology for raisins and grapes, which is applied in the field of drying raisins to change the appearance characteristics and flavor of raisins. It can solve the problems of being unsuitable for popularization and application by ordinary fruit farmers, high cost, and complicated structure, and achieves obvious market value, low cost, and fast drying time. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

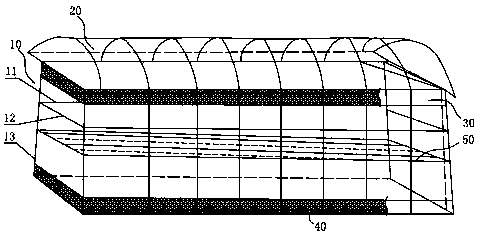

[0039] As the first embodiment of the drying device used in the drying method for changing the appearance and flavor of raisins according to the present invention, its structure is as follows: figure 1 As shown, it includes a bracket 10 and a vaulted top 20 located on the top of the bracket 10 . Wherein the bracket 10 is a frame structure formed by overlapping the transverse rods 12, the longitudinal rods 11 and the vertical rods 13, and the materials used to overlap the above brackets are wooden rods, steel pipes and the like. In this embodiment, the width of the drying device is determined according to the local wind direction, wind speed, etc., and is usually set at 1.5-2m; The demand is determined, usually 1-20m; the height of the drying device is generally 1.5-2.5m, which is convenient for ordinary people to operate.

[0040] In this embodiment, several layers of brackets 50 are arranged inside the bracket 10, and the brackets 50 are used for hanging and drying grapes th...

Embodiment 2

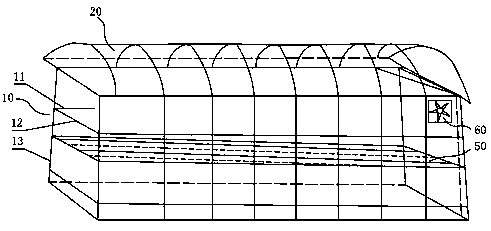

[0046] As the second embodiment of the drying device used in the drying method for changing the appearance and flavor of raisins in the present invention, its structure is as follows: figure 2 As shown, the difference between this embodiment and the first embodiment lies in the ventilation devices used. In this embodiment, its ventilating device comprises the air outlet that is located on the greenhouse film or the plastic light-transmitting film, is provided with exhaust fan 60 on this air outlet, and exhaust fan 60 is powered by common civil electricity, certainly, in the field power supply facility In the case of imperfections, it can also be powered by solar panels or small wind turbines. In the drying device of this embodiment, the air is exhausted when the humidity is high in the early stage of drying, and the air can also be artificially exhausted when the temperature is high at noon every day to reduce the temperature in the device and speed up the drying speed.

[0...

Embodiment 3

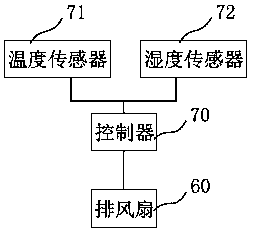

[0050] As the third embodiment of the drying device used in the drying method for changing the appearance and flavor of raisins according to the present invention, its structure is as follows: figure 2 , image 3 As shown, the main structure is the same as the drying device of the second embodiment. The difference between this embodiment and the second embodiment is that it also includes a controller 70, a temperature sensor 71 and a humidity sensor 72. The above-mentioned controller 70 is connected with the temperature sensor 71 respectively. , the humidity sensor 72 and the exhaust fan 60 are electrically connected. When the temperature and humidity exceed the limit value, the exhaust fan will run automatically, thereby reducing the temperature inside the device and speeding up the drying speed. Preferably, in this embodiment, the limit value of temperature is 45° C., and the limit value of humidity is 60%.

[0051] The drying device of this embodiment is relatively simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com