Automatic attachment device

An attachment and automatic technology, applied in lamination devices, lamination auxiliary operations, chemical instruments and methods, etc., can solve the problems that are difficult to meet the needs of group automation production, affect the product yield, sticking deviation or dislocation, etc., to achieve the goal of sticking Accurate and reliable, saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

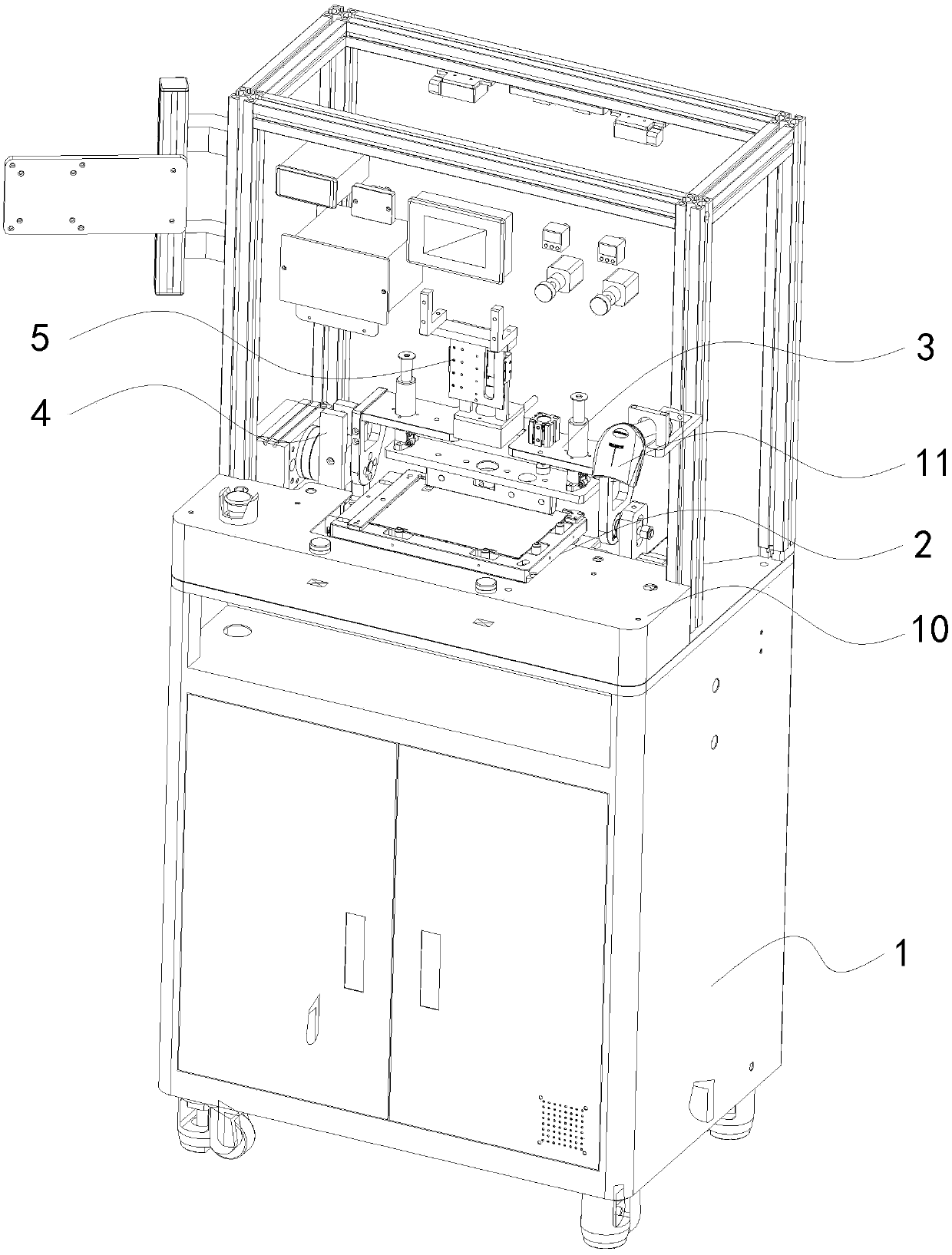

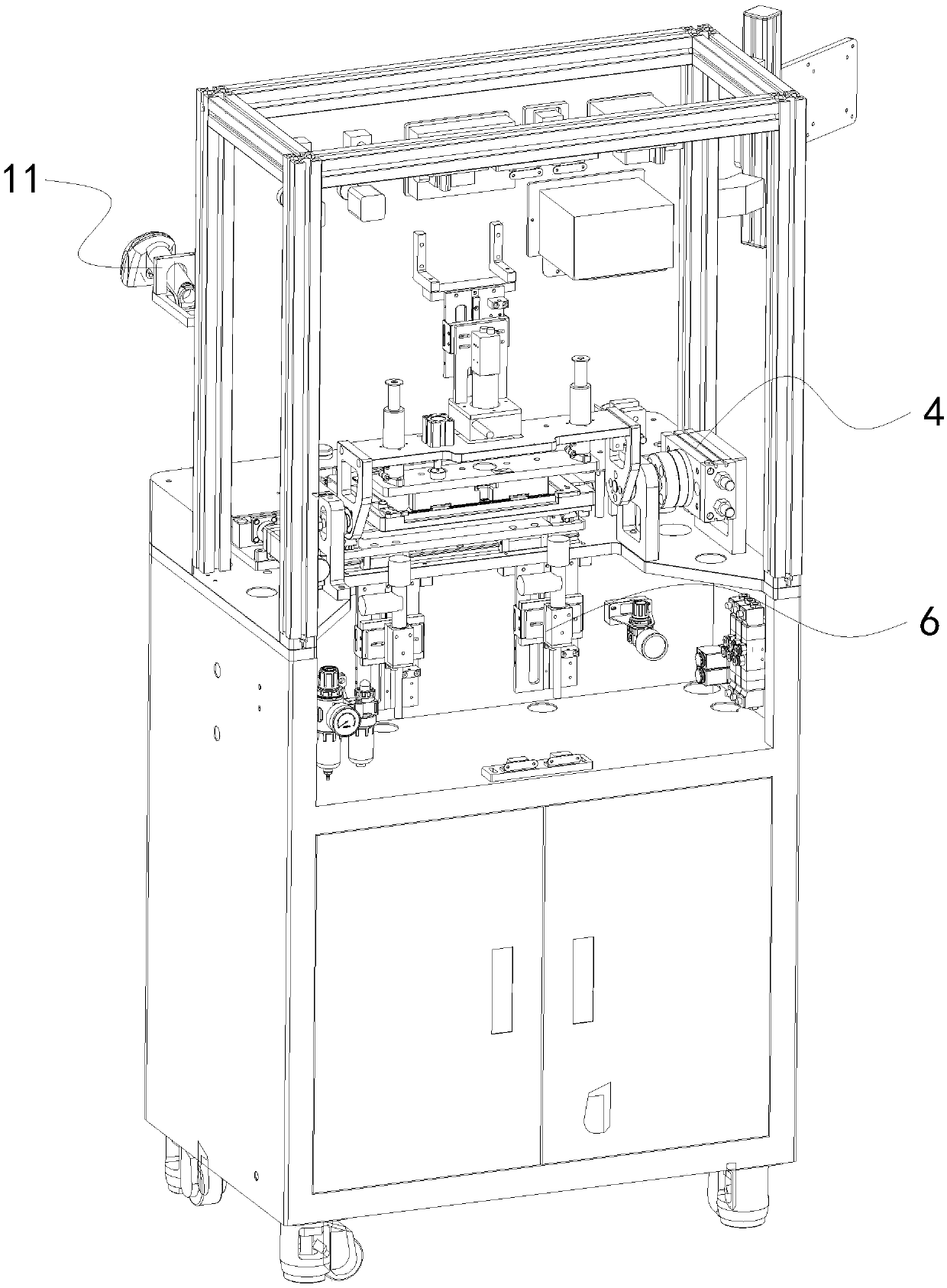

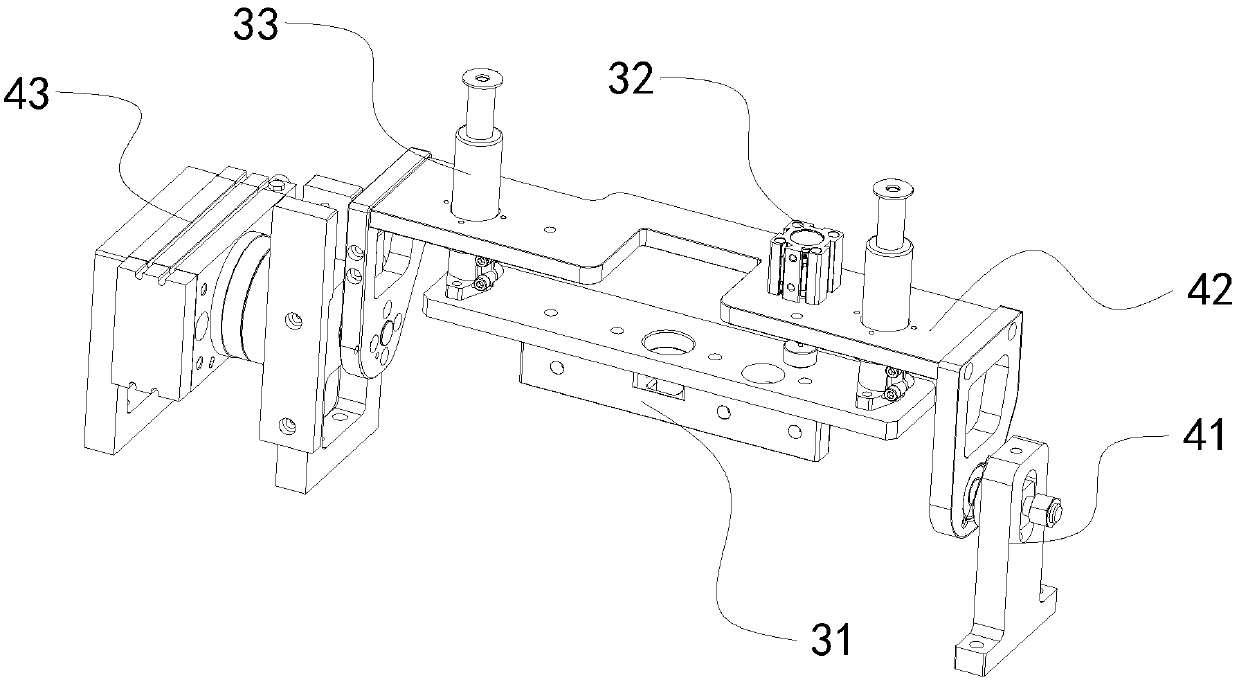

[0024] like Figure 1 to Figure 2 As shown, the automatic attaching device includes a frame 1, a workbench 10 is arranged on the frame 1, a lower mold assembly for placing a backlight module is arranged on the workbench 10, and a soft The board is attached to the upper mold assembly 3 on the backlight module of the lower mold assembly and the turning mechanism 4 that drives the upper mold assembly 3 to turn over; the frame 1 is also provided with a detection device for detecting the position of the lower mold assembly Mechanism and adjustment mechanism 2 for adjusting the position of the lower mold assembly. The detection mechanism includes a CCD camera assembly that detects and calculates the distance between the marking point of the backlight module and the center point of the soft board. The lower mold assembly is placed to be For the backl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com