Automobile rim film automatic attachment mechanism

A technology of automobile wheel and rim film, which is applied to household appliances, other household appliances, household components, etc., which can solve the problems of high labor cost, time-consuming and laborious, and low efficiency, so as to ensure the quality of attachment, save labor cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

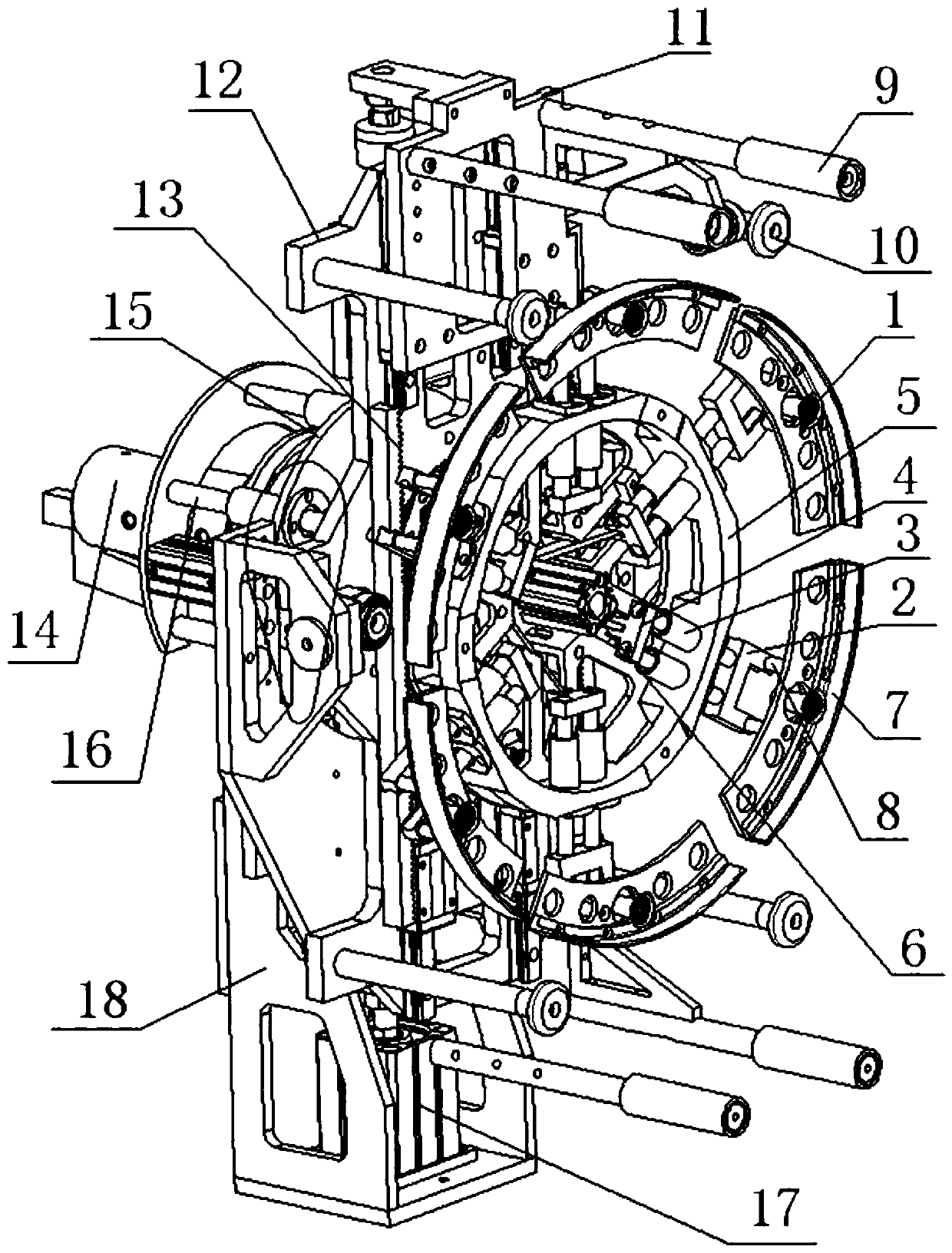

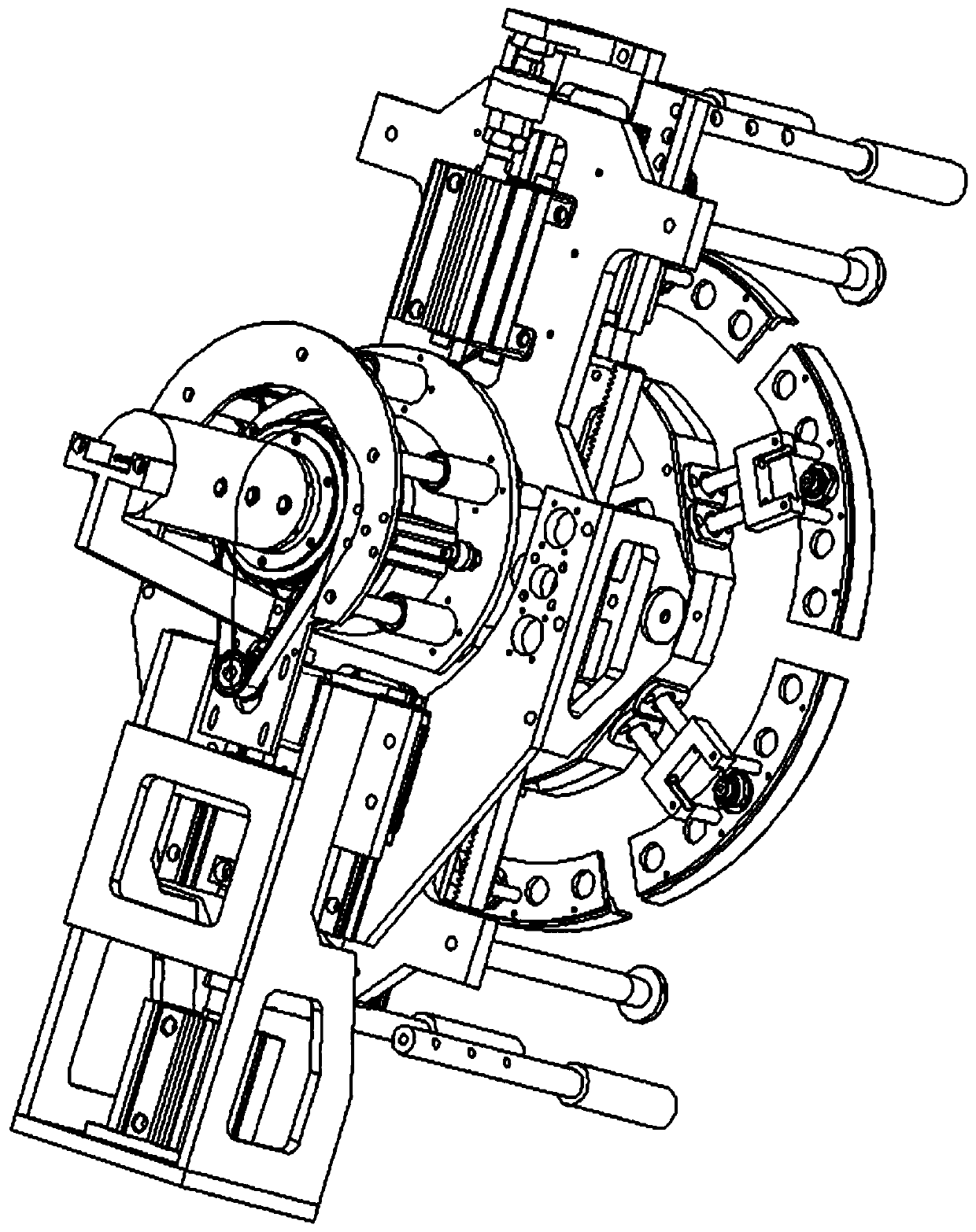

[0013] Attached below figure 1 , 2 The specific embodiment of the present invention will be further described.

[0014] Automobile rim film automatic attachment mechanism, including guide post guide sleeve fixing seat 4, cylinder 6, silicone disc 7, tire fixing rod 9, tire limit post mounting plate 12 and gear rotating motor 14; tire limit post mounting plate 12 Both ends of the front are slidably connected with a tire fixing rod mounting plate 11 through a rack and pinion assembly 13, and two tire fixing rods 9 are installed on the tire fixing rod mounting plate 11. The limit column mounting plate 12 is equipped with a tire limit column 10; the front end of the cylinder 6 is provided with a floating joint, the cylinder 6 is fixed on the rack and pinion assembly 13, and the cylinder 6 is connected to several guide post guide sleeve fixing seats. 4 connection, the guide post guide sleeve fixing seat 4 is connected with the suction cup mounting base 2 through the guide post gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com