Garlic sowing machine

A planter and garlic technology, which is applied in the field of agricultural machinery, can solve the problems of not being able to meet the planting requirements, and cannot ensure that the garlic seed scales are facing upwards, and achieve the effects of reducing planting steps, simple structure, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

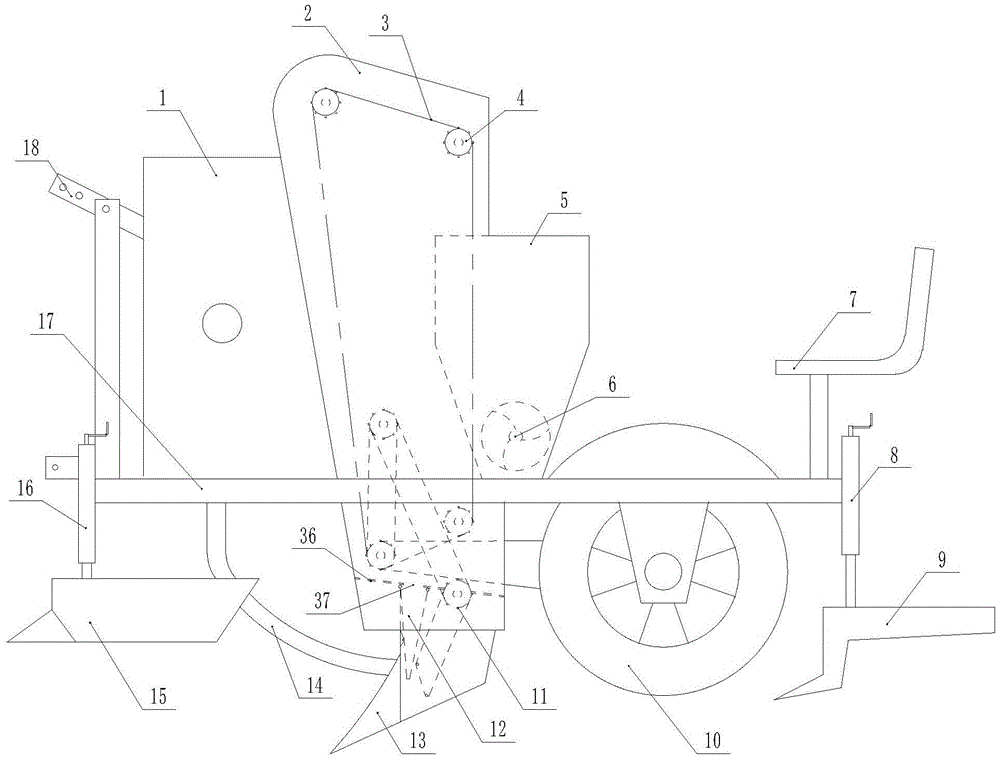

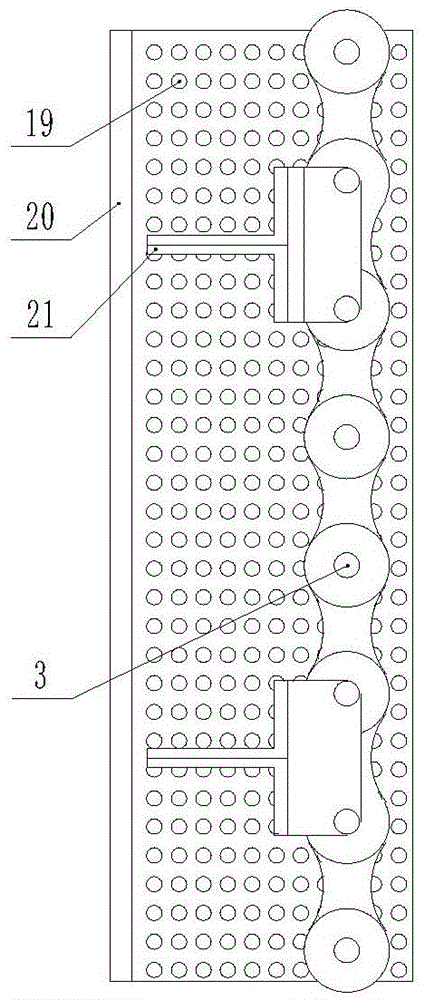

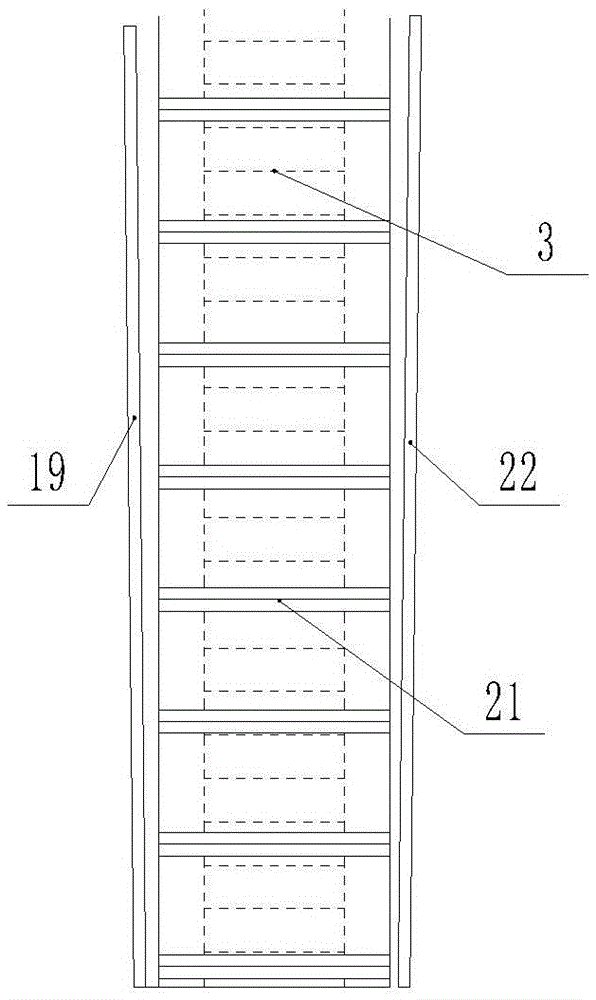

[0027] Embodiment 1: a kind of garlic seeder, comprises frame 17, and described frame 17 is equipped with traveling wheel 10 and traction mechanism 18, and described garlic seeder is also installed with seed box 5, adjustment mechanism 2, garlic seed opening. Groove 13, the adjustment mechanism 2 includes a transmission sprocket 4 and a transmission chain 3, the transmission chain 3 is provided with a supporting plate 21, and the two sides of the transmission chain 3 are respectively provided with adjustment holes with hole-like structures. Baffle plate A19, adjusting baffle plate B22, the distance between said adjusting baffle plate A19, adjusting baffle plate B22 gradually decreases, and forms a closed channel for the movement of conveying chain 3 and supporting plate 21 with chain baffle plate 20 , the bottom of the adjustment mechanism 2 is provided with a sowing baffle 36, and the sowing baffle 36 has a sowing opening 37, and the sowing opening 37 is located at the rear of...

Embodiment 2

[0028] Embodiment 2: a garlic seeder, the planting mechanism 11 is provided below the sowing port 37, and the planting mechanism 11 includes a seed distributor 12, a seed pressing plate 24, a seed pressing transmission chain 25, and a seed pressing transmission wheel 23 And the steering device 26, the seed distributor 12 includes a seeder 28, a sowing baffle 27; wherein the seeder 28 includes a seeder plate 32, an arc-shaped cavity 31, and a hook plate 38, and is hinged to the frame through the pin hole A30 17. The sowing baffle 27 is located at the opening of the arc-shaped cavity 31, which includes a side plate 34 and a sowing baffle opening 35, and is fixed to the frame 17 through the pin hole B33; the seed pressing plate 24 is installed on the pressing On the drive chain 25. All the other parts are identical with embodiment 1.

Embodiment 3

[0029] Embodiment 3: a garlic seeder, the seeder 28 is connected with the garlic seed opener 13 through a spring device 29 . The frame 17 is provided with a fertilizer box 1, and the fertilizer box 1 is connected with the garlic seed opener 13 through the fertilizer pipeline 14. An auger device 6 is provided in the seed box 5 . All the other parts are identical with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com