Judgment method for the reason of lithium battery performance degradation

A lithium battery, performance technology, applied in the field of judging the cause of lithium battery performance decline, to achieve the effect of simple internal reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

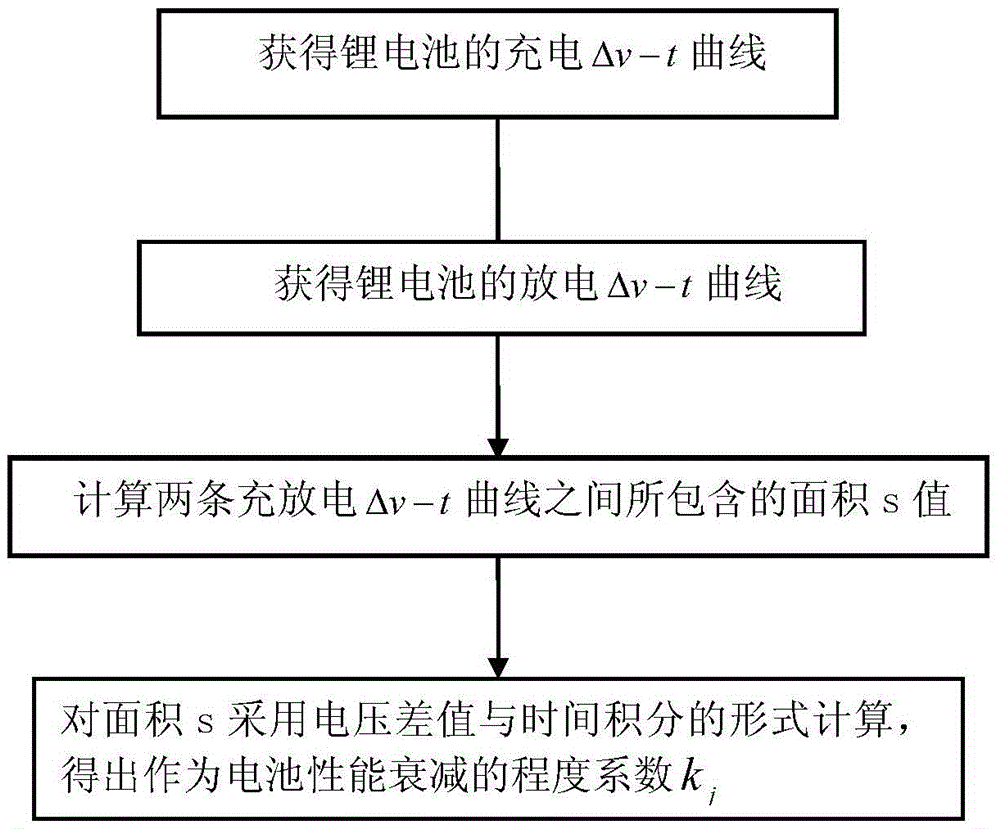

[0044] The method for judging the cause of lithium battery performance degradation of the present embodiment, the steps are as follows:

[0045] The first step is to obtain the charging Δv-t curve of the lithium battery:

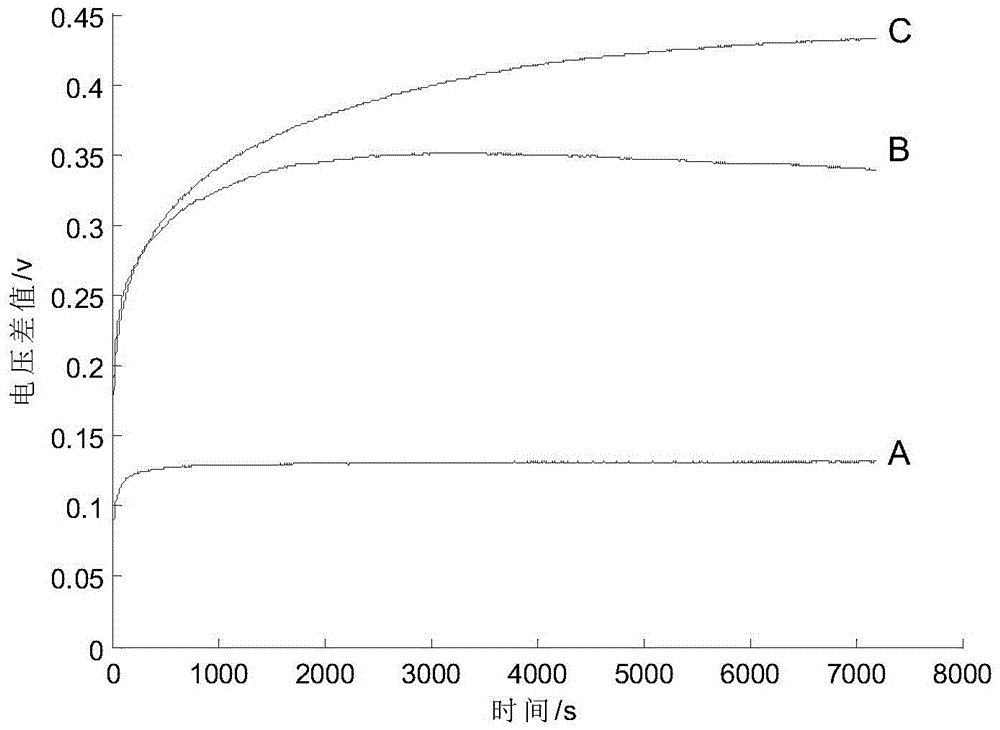

[0046] During the lithium battery charging process, take the two-hour charging time interval from the beginning of charging the lithium battery to the moment when it reaches the highest rated voltage and stop charging. Lithium battery voltage value v i , i=0,1,2,...,8200, where the first voltage value collected is the highest rated voltage value reached immediately before the lithium battery stops charging, as the recorded voltage value at 0 time, denoted as v 0 , using the voltage value v recorded at the subsequent moment i Subtract the voltage value v 0 Get the voltage difference, automatically follow the abscissa time to connect the ordinate voltage difference point, and obtain a charging Δv-t curve. The above is divided into two periods, and the lithi...

Embodiment 2

[0059] Except that the third step is changed to "Combine any charging Δv-t curve obtained in the first step above with a discharging Δv-t curve obtained in the second step adjacent to its recording sequence, and calculate the charging Δv-t curve t curve and its subsequent discharge Δv-t curve included area s value ", other are the same as embodiment 1.

Embodiment 3

[0061] Except that the third step is changed to "Combine any charging Δv-t curve obtained in the first step above with a discharging Δv-t curve obtained in the second step adjacent to its recording sequence, and calculate each charging Δv-t curve The average of the area s value included between the t curve and its previous discharge Δv-t curve and the area s value included between each charging Δv-t curve and its subsequent discharge Δv-t curve Value ", other is with embodiment 1.

[0062] The acquisition record involved in the above-mentioned embodiment is this lithium battery voltage value v i The equipment and methods involved, and the involved drawing and calculation methods are within the grasp of those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com