A kind of automatic discharge device of powder

An automatic discharge device and powder technology, applied in packaging, loading/unloading, transportation and packaging, etc., can solve the problems of high labor cost, difficult maintenance, low efficiency, etc., to solve the problem of high work intensity and low labor efficiency , The effect of fast sorting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

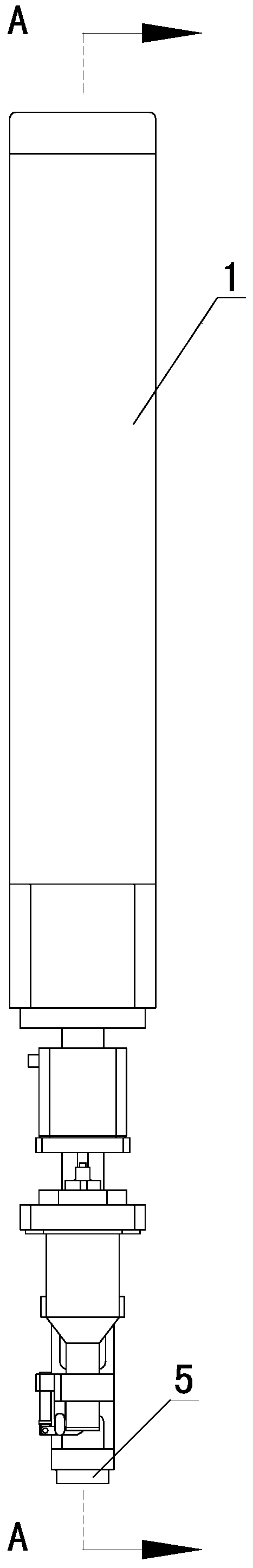

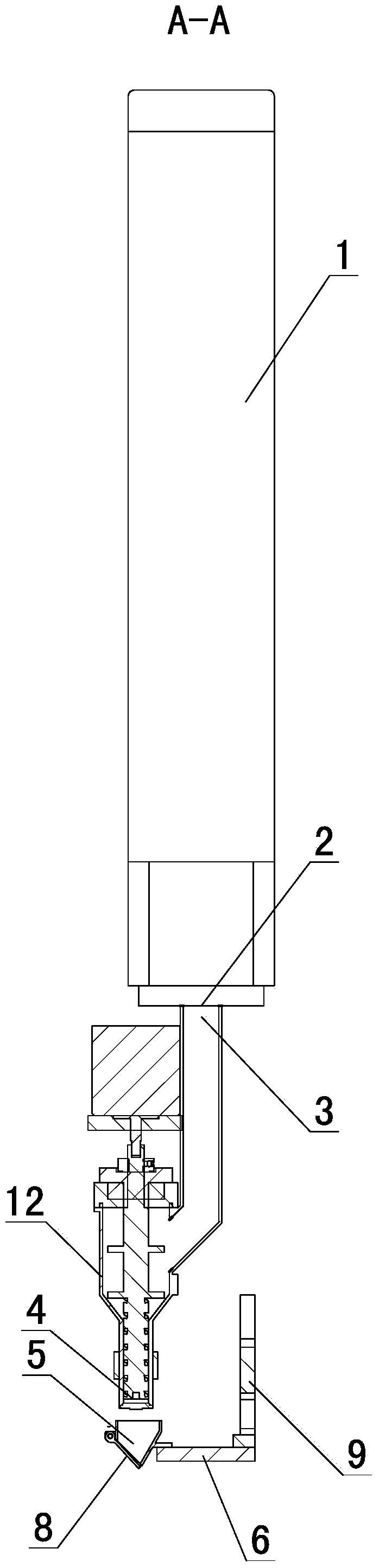

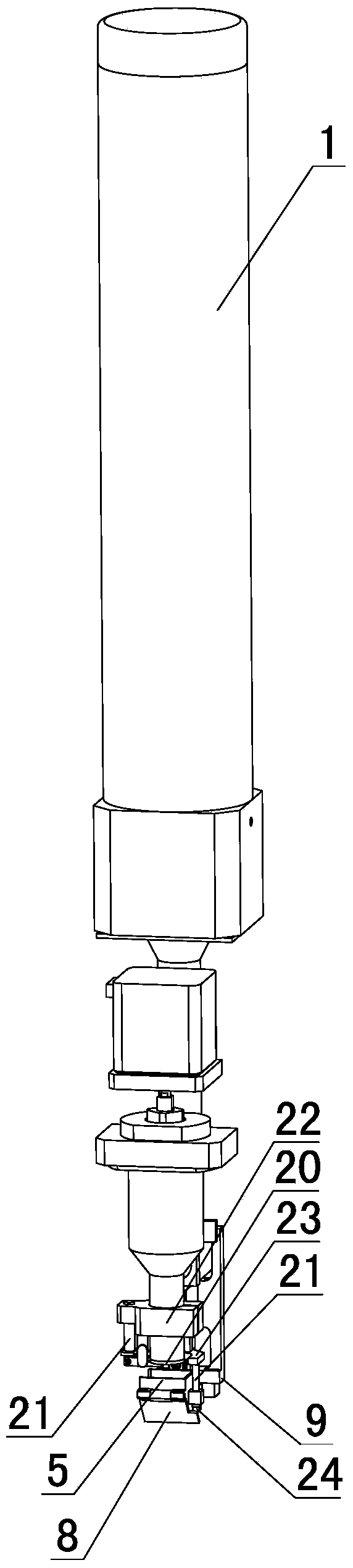

[0037] Example: see attached Figure 1~3 As shown, an automatic powder discharge device is used for powder automatic quantitative sorting equipment (not shown in the figure), and the powder does not include traditional Chinese medicine; the equipment includes a frame. The discharge device includes a storage tank 1 vertically arranged from top to bottom, a feeding mechanism and a weighing mechanism; the bottom of the storage tank 1 is a discharge opening 2; the discharging mechanism has a feeding port 3 and a discharge port 4, the feed port 3 communicates with the discharge port 2, the discharge port 4 is set facing downwards corresponding to the weighing mechanism, and the discharge mechanism is used to remove the material in the storage tank 1 The powder is transferred to the weighing mechanism;

[0038]The weighing mechanism is positioned below the feeding mechanism, and includes a carrying device 5 for carrying powder and a load cell 6 (7); the carrying device 5 is directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com