Stacking manipulator for machine room floor production

A machine room floor and manipulator technology, which is applied in the field of palletizing manipulators, can solve problems such as not being suitable for the needs of industry users, and achieve the effect of simple structure, convenient use, and reliable and stable palletizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

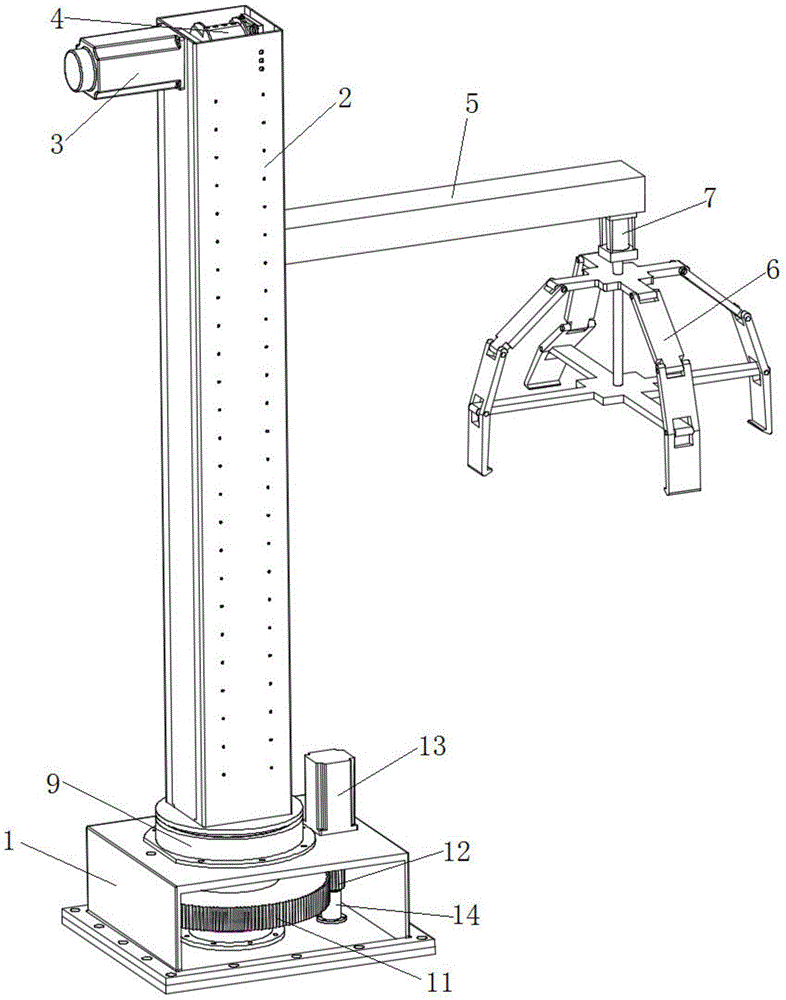

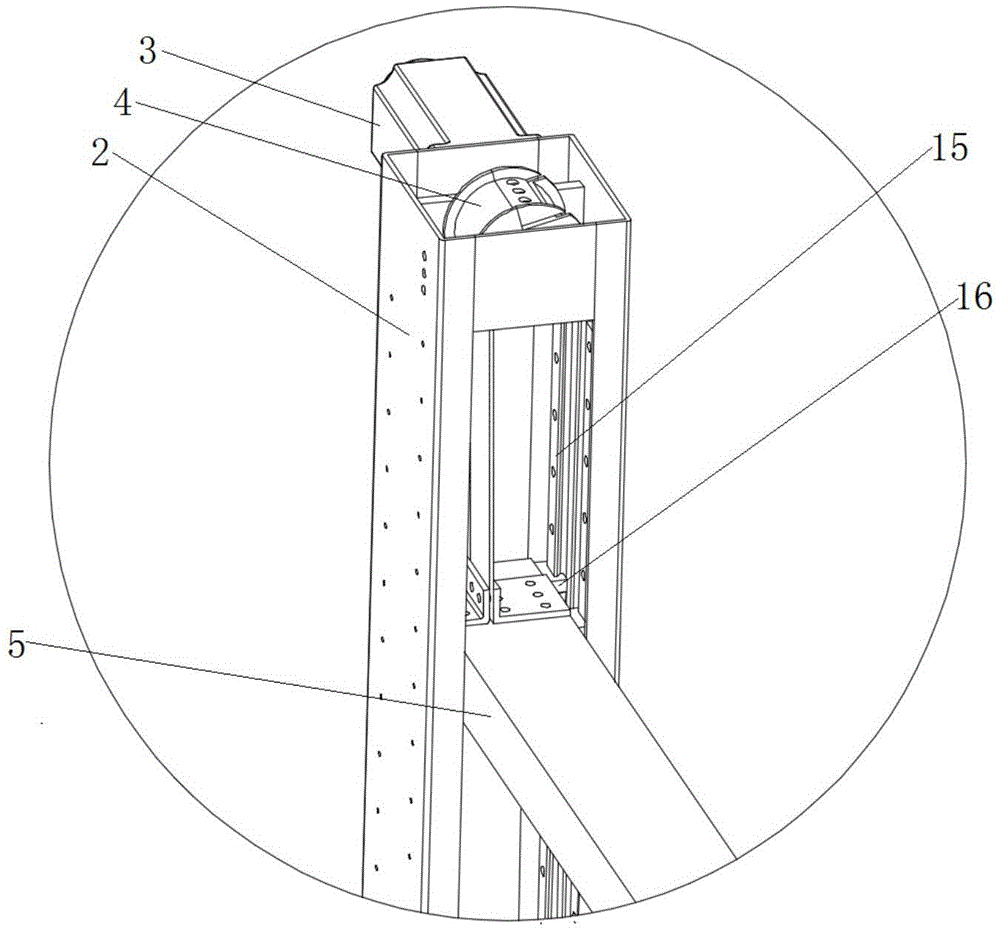

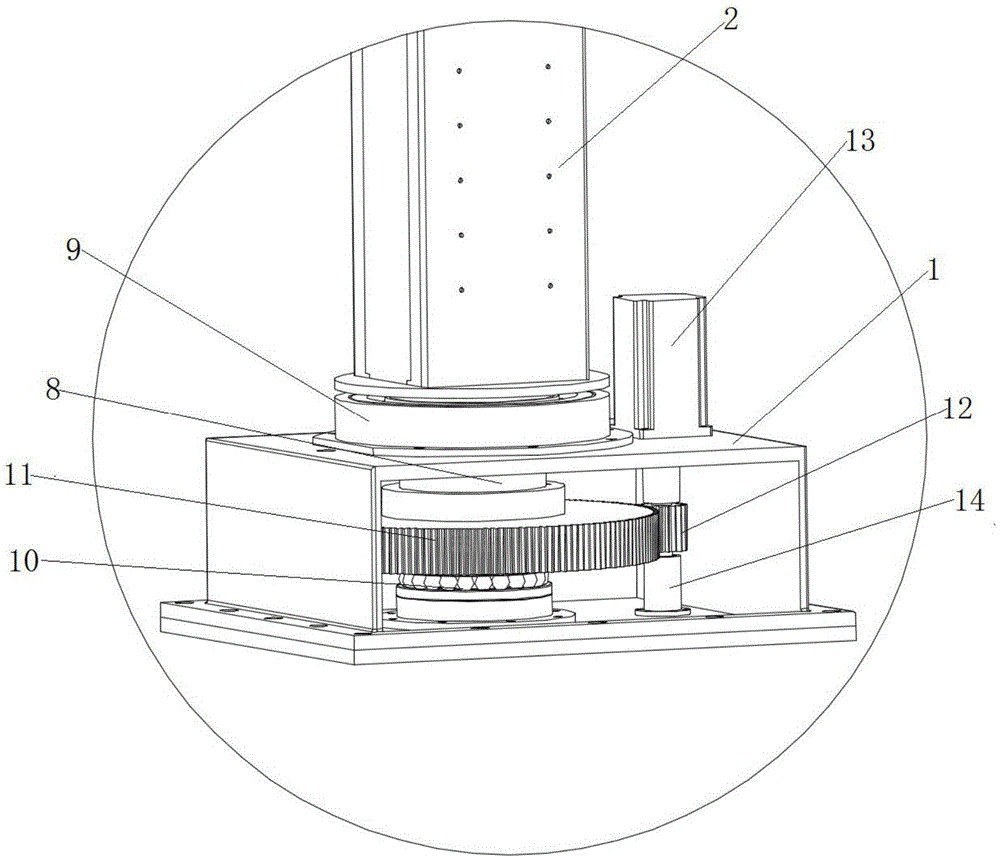

[0023] combine figure 1 , figure 2 with image 3 , a palletizing manipulator for machine room floor production in this embodiment includes a base 1, a column 2, a rotary mechanism, a lifting mechanism and a beam 5, the column 2 is vertically installed on the base 1 through the rotary mechanism, and the column 2 is controlled by the rotary mechanism In this embodiment, the rotary mechanism includes a rotary shaft 8, a thrust bearing 10, a driven gear 11, a driving gear 12, a rolling bearing installed on the top plate of the base 1 through a rolling bearing seat 9, and a rotary drive motor fixed on the top plate of the base 1 13. The upper end of the rotary shaft 8 is fixedly connected with the column 2, and the lower end of the rotary shaft 8 passes through the rolling bearing, the top plate of the base 1, the driven gear 11 and the thrust bearing 10 in sequence, and then connects with the bottom plate of the base 1 through the flange seat; the rotary drive motor 13 After pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com