A twin-platen squeeze casting machine for light metal

A technology of squeeze casting machine and double template, which is applied in the field of squeeze casting, can solve the problems that the four locking nuts cannot be adjusted independently, the product quality cannot be fully guaranteed, the force of the large bar is uneven, etc., and the die casting cycle can be shortened. time, increased plant capacity and output, and the effect of running fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

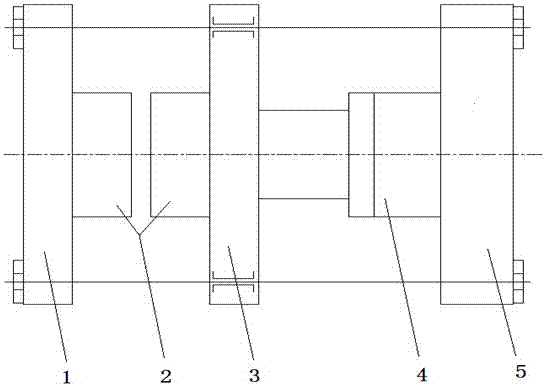

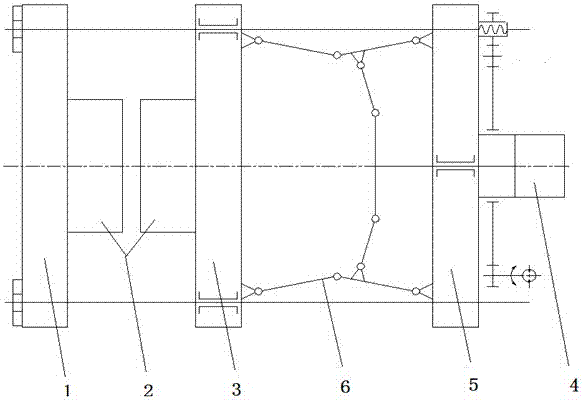

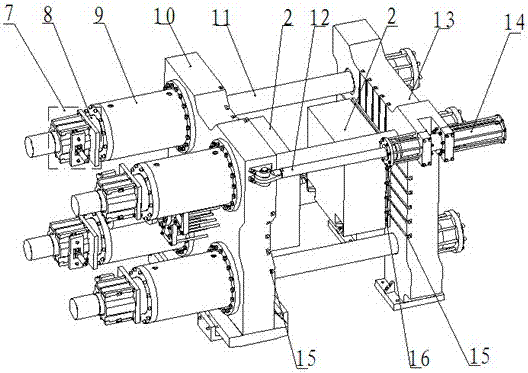

[0026] The invention is a double-platen squeeze casting machine for light metals, which is suitable for squeeze casting of light metals such as aluminum and magnesium alloys, and has practical reference value for squeeze casting of other metals.

[0027] The double-plate squeeze casting machine of the present invention comprises a mold clamping device 7, a clamping oil cylinder, a movable plate 10, a large bar 11, a mold-moving oil cylinder, a fixed plate 13, a T-shaped groove 15, a T-groove bolt 16 and a base, wherein the lock The mold device 7 mainly includes a mold clamping cylinder, a first lock nut 17, a long screw 19, a steel plate 21 and a second lock nut 22, and the mold clamping cylinder is mainly equipped with a mold clamping piston 18 and a mold clamping cylinder 20 , the mold clamping cylinder is mainly equipped with a mold clamping piston sleeve 8 and a mold clamping cylinder 9, and the fast mold moving cylinder is mainly equipped with a mold moving piston 12 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com