Control method of spray coating robot

The technology of a spraying robot and control method, which is applied in the direction of spraying devices, etc., can solve the problems of inconvenient flow adjustment of nozzles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below by means of specific embodiments:

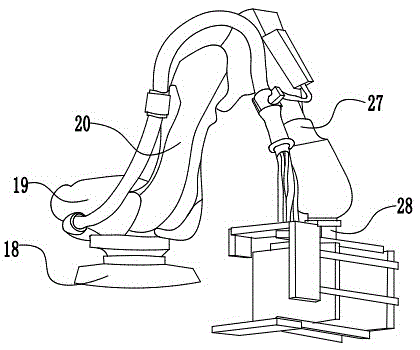

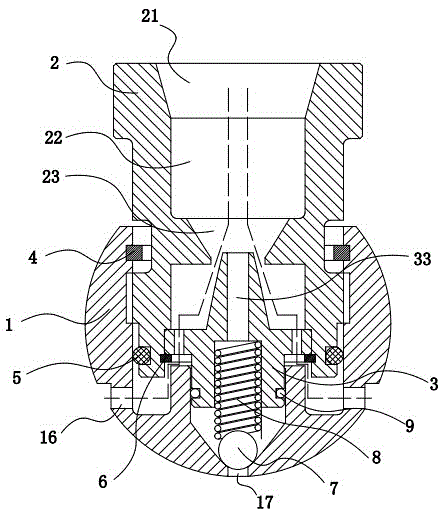

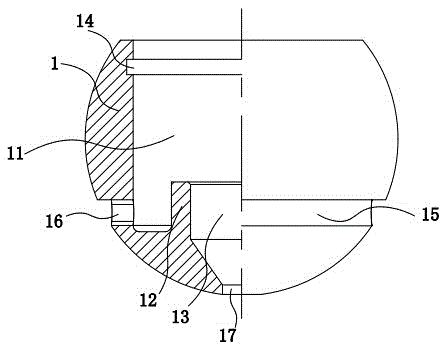

[0033] The reference signs in the drawings of the description include: ball head seat 1, first groove 11, first protrusion 12, first through hole 13, first card groove 14, lower sealing groove 15, air inlet 16, feed Port 17, nozzle body 2, discharge port 21, diffusion chamber 22, vacuum chamber 23, disc installation hole 24, second groove 25, second card slot 26, nozzle 3, disc 31, air passage 32, the second One paint channel 33, the second paint channel 34, the third card slot 35, the nozzle body snap ring 4, the nozzle body seal ring 5, the nozzle snap ring 6, the one-way valve ball 7, the compression spring 8, the nozzle seal ring 9, the base 18. The first mechanical arm 19, the second mechanical arm 20, the third mechanical arm 27, the connecting arm 28, the connecting plate 29, the connecting bar 30, the pipeline connecting plate 36, the upper spraying plate 37, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com