Composite filter cloth equipped with filter membrane

A composite filter and filter cloth technology, applied in the field of filter cloth, can solve the problems of short service life, difficult to filter out dust particles, low strength of filter membrane, etc., and achieve the effect of long service life, enhanced strength and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

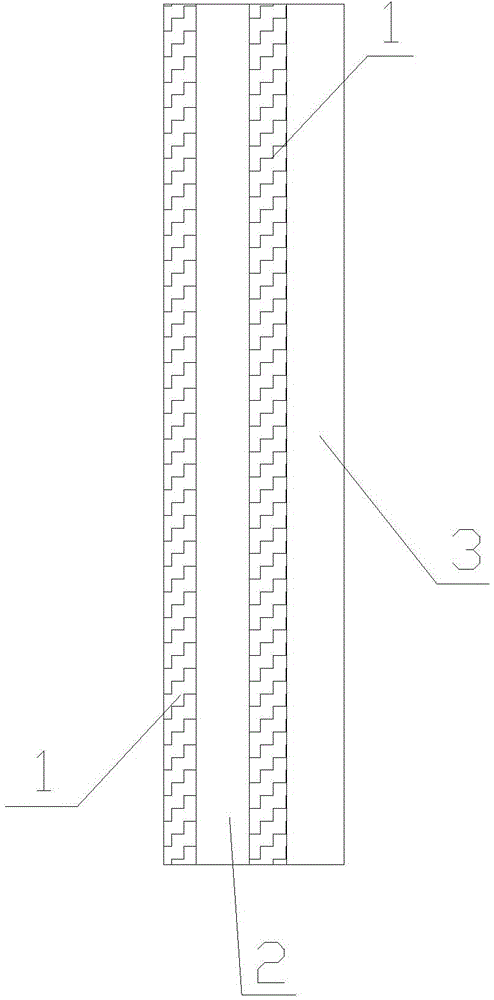

[0011] Such as figure 1 Shown, be provided with the composite filter cloth of filter membrane, be made of filter cloth 2 and filter membrane 1, described filter cloth 2 comprises glass fiber filter cloth, polytetrafluoroethylene filter cloth or basalt filter cloth, described filter cloth 2 A filter membrane 1 is provided on one side or both sides, and the filter membrane 1 includes a polyvinyl fluoride filter membrane; the filter cloth 2 and the filter membrane 1 are bonded or hot-pressed to form an integral structure.

[0012] The filter cloth 2 also includes a filter cloth formed by blending glass fiber and polytetrafluoroethylene fiber or basalt fiber and polytetrafluoroethylene fiber. In this embodiment, the composite filter cloth is composed of two layers of filter cloths 2 and 3, and a filter membrane 1 is arranged between the filter cloth 2 and the filter cloth 3, wherein the outer surface of the filter cloth 2 is provided with a filter membrane 1, The filter cloth 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com