Lotus leaf dumpling apparatus

A technology of lotus leaf and pre-pressed noodle roller assembly, which is applied in the directions of winding dough sheet machines, baking, dough forming and cutting combination, which can solve the problems of manpower and time consumption, unique and complicated shape, time-consuming and labor-consuming, etc. , to achieve the effect of improving efficiency and saving labor loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

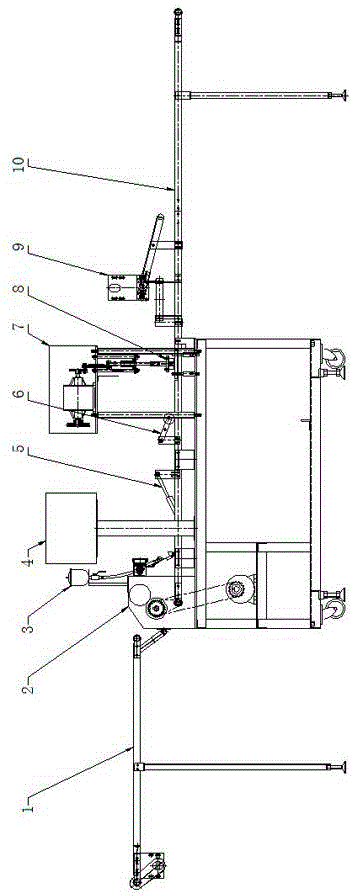

[0010] refer to Figure 1-2 , the specific embodiment adopts the following technical solutions: it consists of a face feeding assembly 1, a pre-pressing roller assembly 2, an oil brushing assembly 3, a control box 4, a stacking assembly 5, a pressing roller assembly 6, a cutter box 7, a mold 8. The leftover material recovery assembly 9 and the rear conveyor belt 10 are composed. The surface feeding conveying assembly 1 is connected with the pre-pressing roller assembly 2. The pre-pressing roller assembly 2 is provided with an oil brushing assembly 3, and the pre-pressing roller assembly 2 is connected with a The rear conveyor belt 10 is provided with a control box 4, a stacking assembly 5, a pressure roller assembly 6, a cutter box 7, a mold 8, and a leftover material recovery assembly 9 on the rear conveyor belt 10.

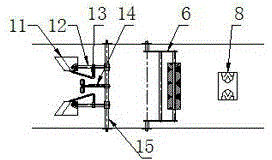

[0011] The stacking assembly 5 includes an inclined flap 11 , an inclined flap support rod 12 , a guide frame 13 , a bracket 14 , and a support rod 15 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com