Locomotive body light weight optimization method

An optimization method and lightweight technology, applied in the field of rail vehicles, can solve problems such as the inability to realize the optimization calculation of multi-design variables, multi-constraint variables and multi-objective variables of the whole vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

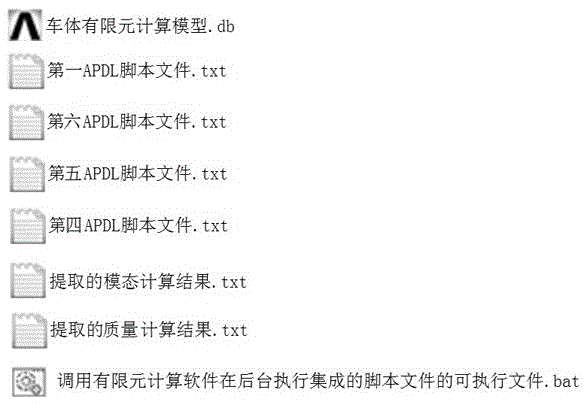

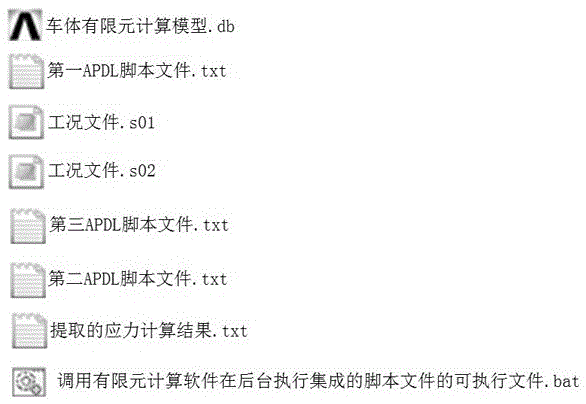

Embodiment Construction

[0034] The Chinese and English symbol meanings of the present invention are explained as follows:

[0035] APDL: The full name is ANSYS Parametric Design Language, which is the parametric design language of ANSYS software.

[0036] task: a process component in isight software.

[0037] DOE: Renamed from the process component task. DOE is Design of Experiments, which is DesignofExperiments in English. The purpose is to determine the best combination of parameters and analyze the relationship and trend between input parameters and output parameters.

[0038] dataexchanger, oscommand, parameter, dataexchanger, calculatestress: application components in isight software.

[0039] parameter: Renamed from the application component dataexchanger.

[0040] calculatestress: Renamed from the application component oscommand.

[0041] getstress: Renamed from the application component dataexchanger.

[0042] calculatefreq+mass: Renamed from the application component oscommand.

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com