Device and method for realizing swing of rotating shaft of turn table

A technology of rocking motion and rotating table, which is applied in the direction of non-electric variable control, instrument, mechanical vibration control, etc., can solve the problems such as difficult adjustment of frequency and amplitude, unstable start and stop, large volume of rotating table, etc., and achieves simple structure, Rocking start and smoothing, effects that improve rocking precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

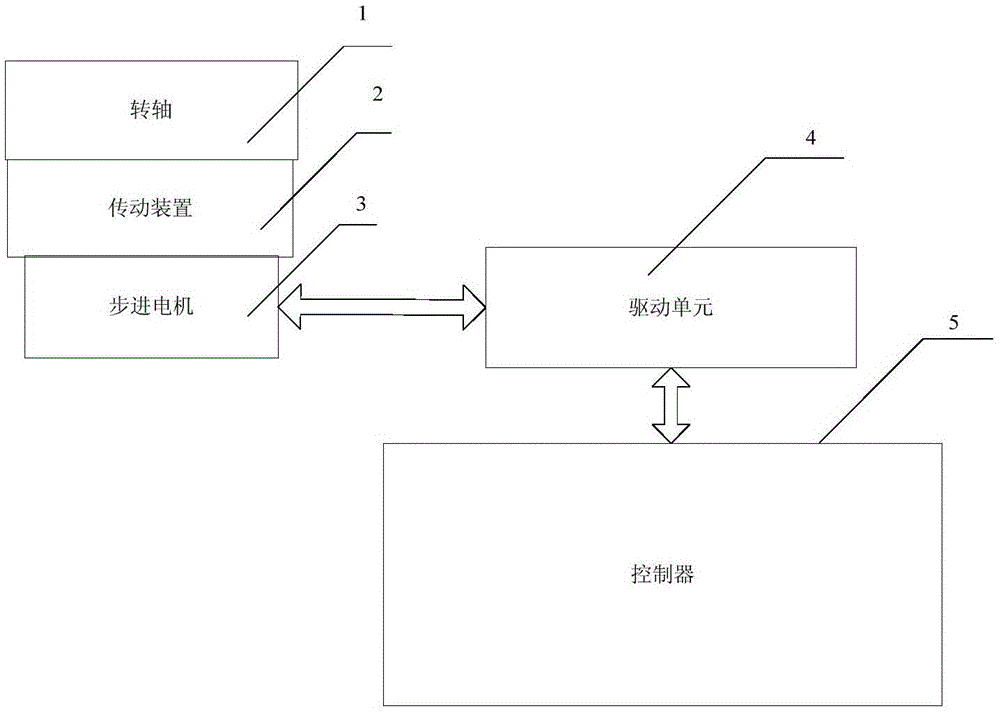

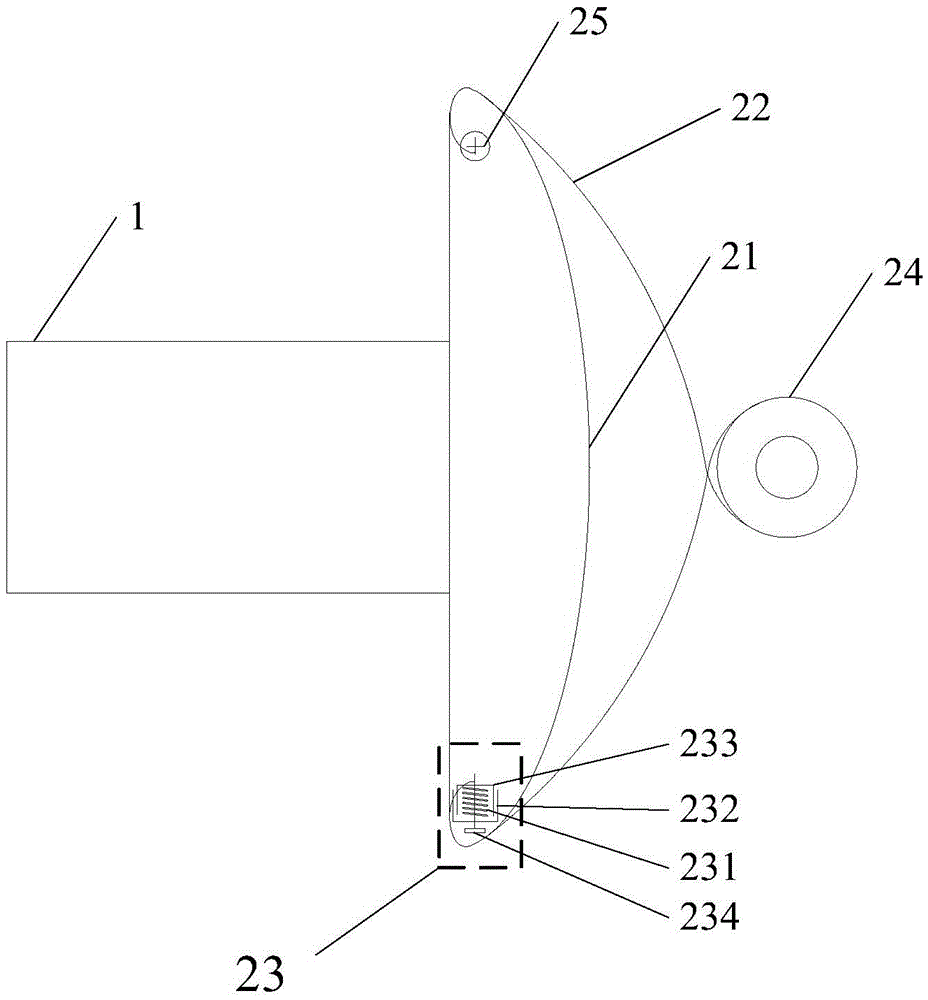

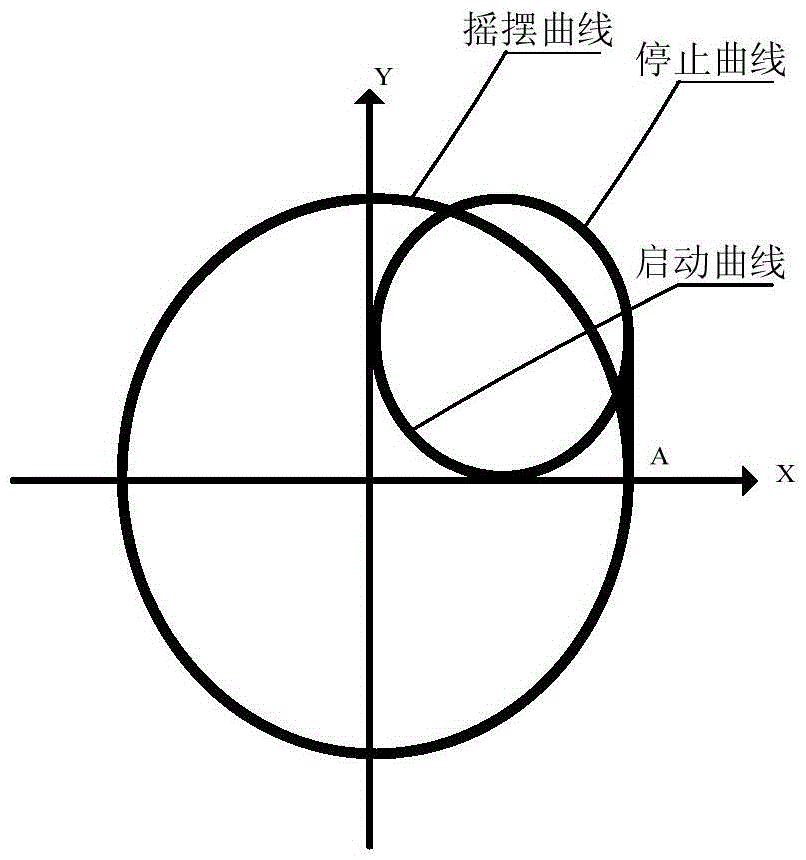

[0036] like figure 1 As shown, the present invention proposes a device for realizing the oscillating motion of the rotary shaft of the rotary table, which includes a rotary shaft oscillating motion device of a transmission device 2, a stepping motor 3, a drive unit 4 and a controller 5, wherein the stepping motor 3 passes through the transmission device 2 Connected to the rotating shaft 1, the controller 5 calculates the amplitude of the swinging motion of the rotating shaft in real time and converts it into a pulse signal and outputs it to the drive unit 4. The driving unit 4 converts the amplitude of the swinging motion of the rotating shaft into a driving signal in real time and outputs it to the stepping motor 3. 3 is rotated under the action of the driving signal, so that the rotating shaft 1 of the rotary table is driven to perform sinusoidal rocking motion through the transmission device 2 .

[0037] In order to further improve the swing accuracy and reduce the cost, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com