Pulling nail locking torque measuring device

A measuring device and a technology for locking torque, applied in the field of standard parts detection, can solve the problems of not being able to truly reflect the installation state of the drawing nails, affecting the physical performance, and not being able to reflect the real state, etc. The effect of avoiding mechanical damage and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below by embodiment the present invention will be further described:

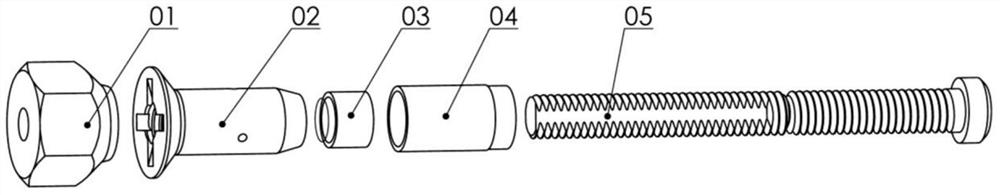

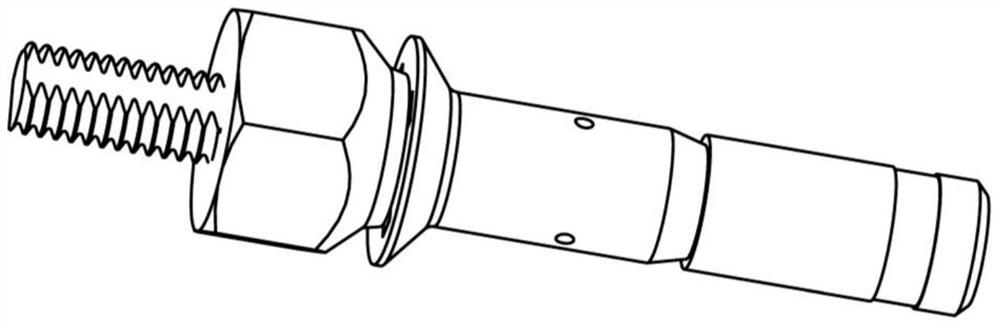

[0028] Please also see Figure 7 and Figure 8 ,in, Figure 7 It is an exploded view of the parts of the screw locking torque measuring device of the present invention, Figure 8 It is a schematic diagram of the structure of the measuring device for locking torque of pulling nails. The nail-pulling locking torque measuring device includes a fixed end 21 , a bracket 22 , a bearing 23 , a retaining ring 24 , a support nut 25 , and a nail-pulling installation interlayer 26 . Wherein, the bearing 23 is assembled on the supporting nut 25, and then put into the bracket 22 of the frame structure together, and the retaining ring 24 is clamped in the slot of the supporting nut 25, so as to prevent the bearing 23 from moving in the axial direction. The fixed end 21 is screwed into the threaded hole of the support nut 25 after passing through the hole at the top of the bracket 22, and its end surface is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com