Spring braking device with breathing structure

A braking device and breathing technology, which is applied to valve devices, brake actuators, engine components, etc., can solve problems such as garbage and water flowing into the interior of the brake chamber, rusting of metal parts, and diaphragm failure. Achieve the effects of reducing the entry of moisture and dust, prolonging the service life, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the accompanying drawings of the embodiments of the present invention, but the following embodiments are only preferred embodiments of the present invention, not all of them. Based on the examples in the implementation manners, other examples obtained by those skilled in the art without making creative efforts all belong to the protection scope of the present invention.

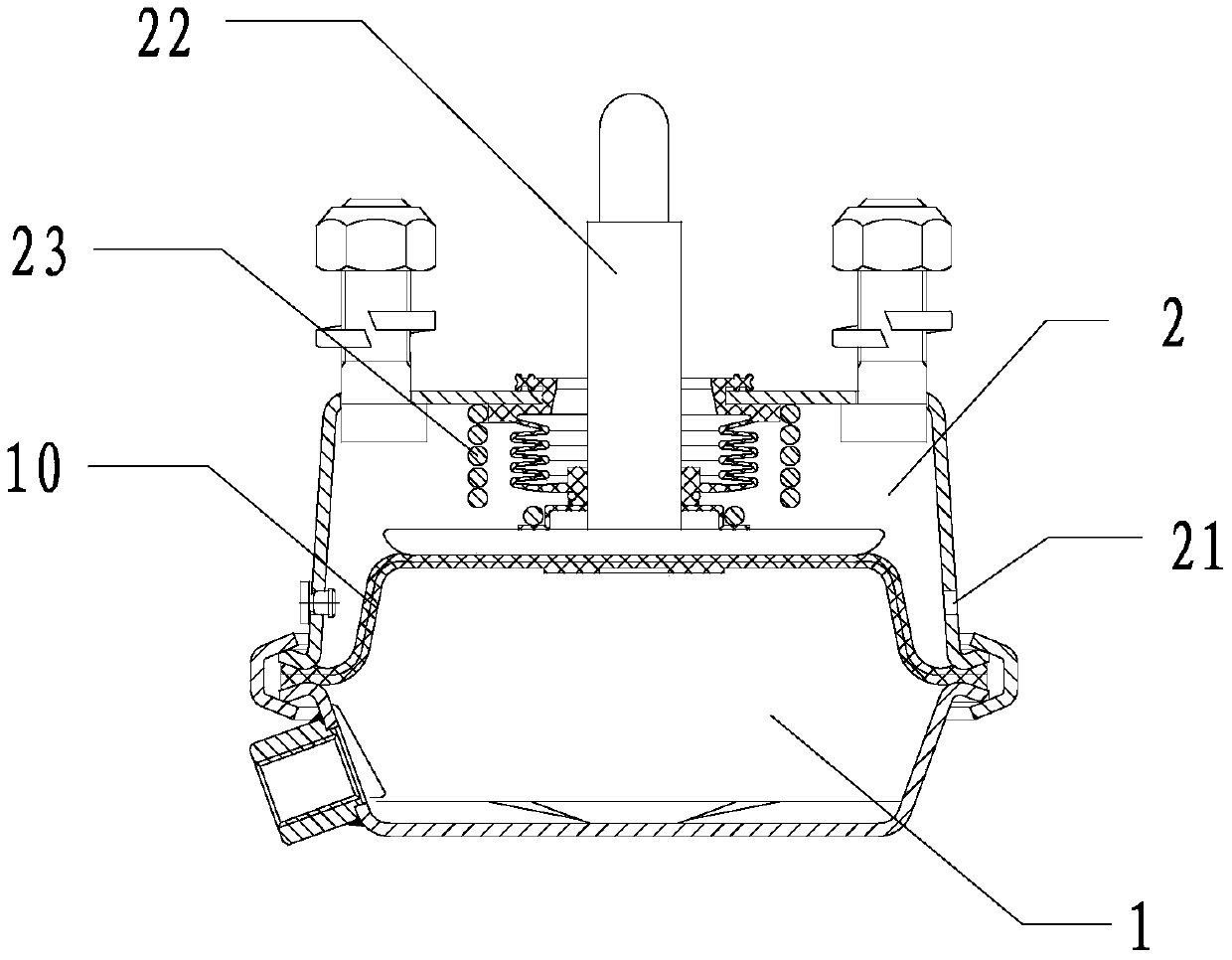

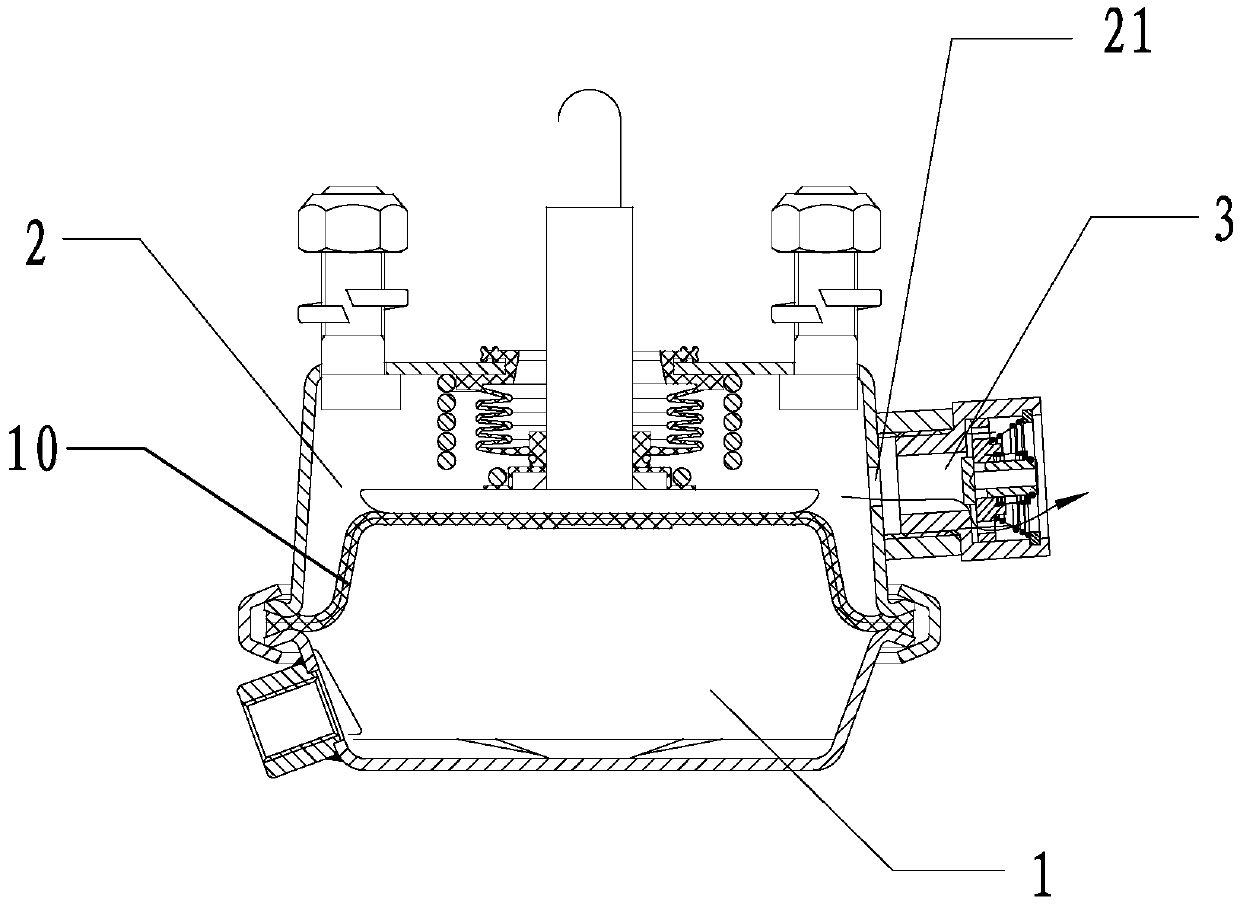

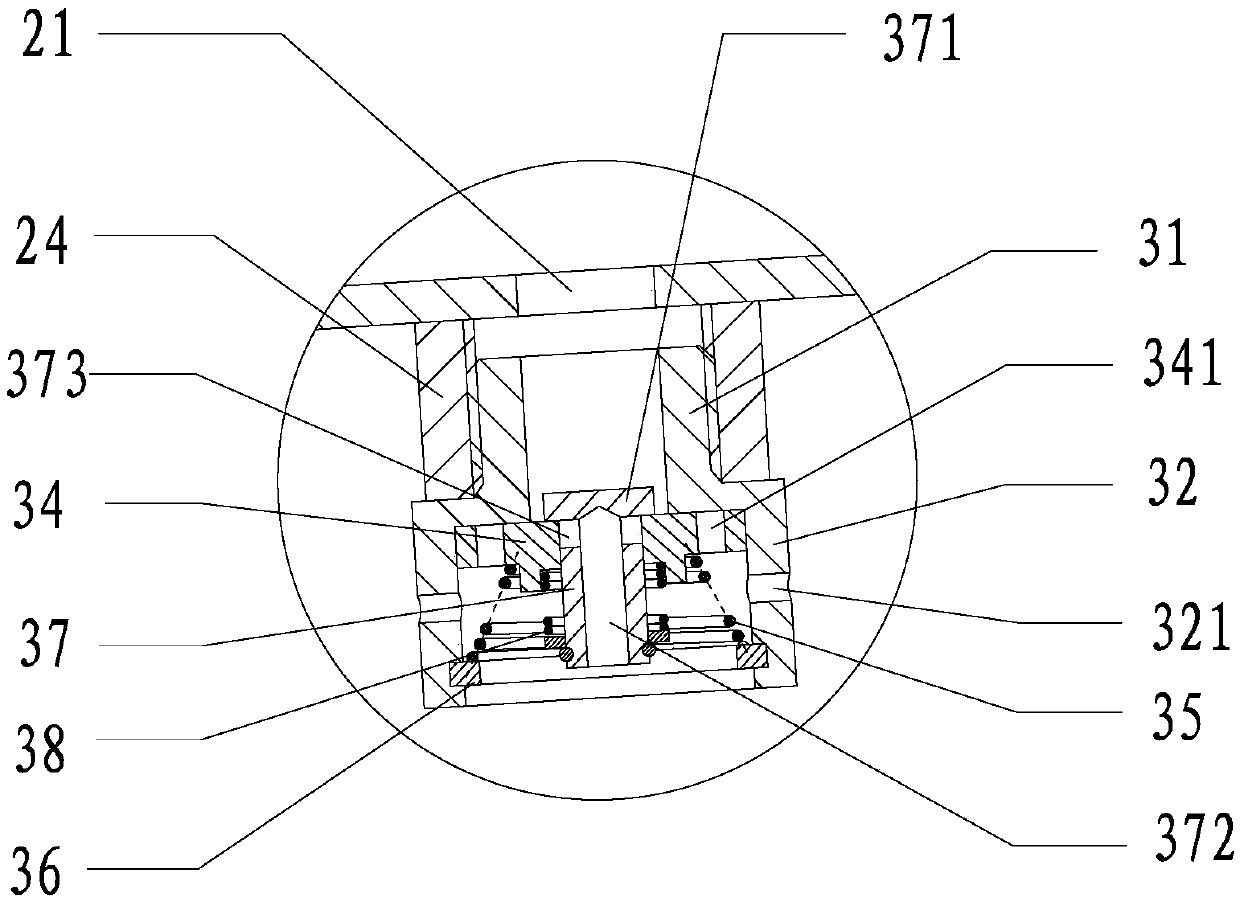

[0023] refer to figure 1 , the spring brake device in the prior art includes a driving chamber 1 and a brake chamber 2, a diaphragm 10 is arranged between the driving chamber 1 and the braking chamber 2, and the driving chamber 1 is provided with an air inlet of the driving chamber. A piston rod 22 and a compression spring 23 are arranged in the dynamic air chamber 2, and a breathing port 21 communicating with the outside world is provided in the brake air chamber 2. When the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com