Oil field surface desanding device

A ground and oilfield technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of lack of effective measures for sand removal in low-temperature heavy oil, so as to improve the quality of crude oil, increase the dilution degree, and reduce mud and sand Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

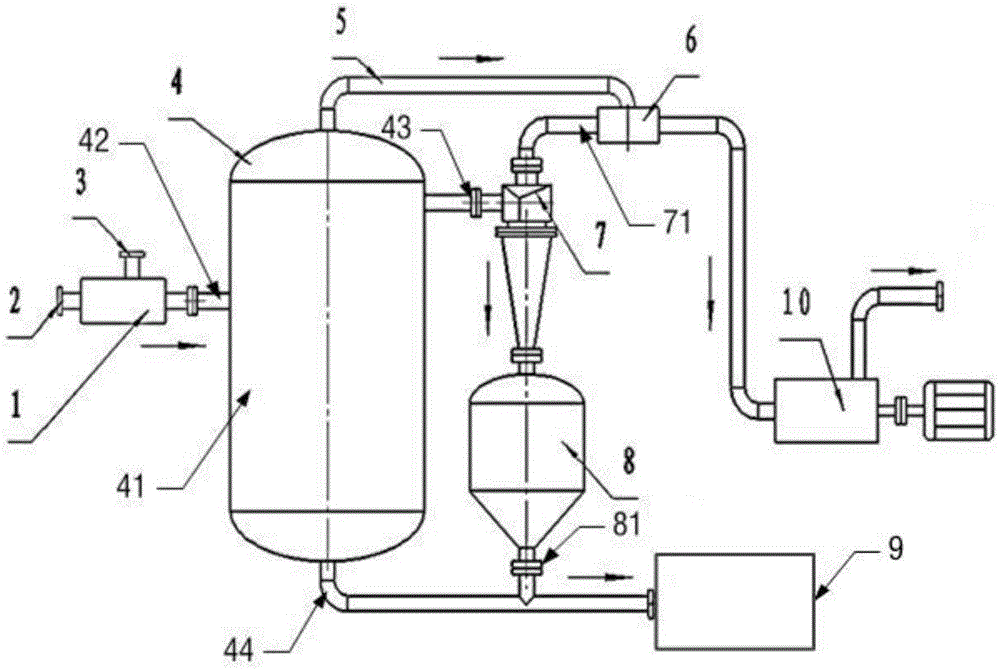

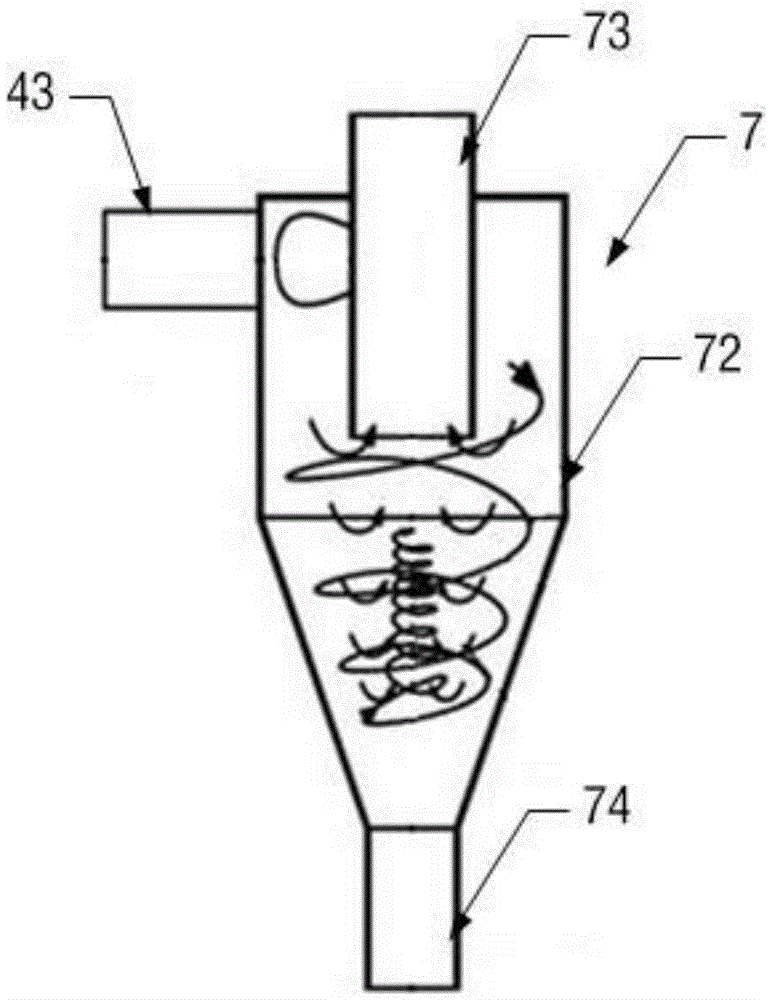

[0022] Such as figure 1 As shown, the oilfield surface desanding device of an embodiment of the present invention generally includes: a mixer 1 for heating and mixing the incoming crude oil with a heating medium and then outputting, and providing a reaction space expansion buffer for the crude oil output by the mixer 1 Tank 4, and liquid-solid separator 7 for liquid-solid separation of crude oil discharged from expansion buffer tank 4.

[0023] The mixer 1 is connected with the surface outlet of the oil production well through a liquid inlet pipe 2, and at the same time is provided with a heat medium interface pipe 3 for receiving the heat medium. The expansion buffer tank 4 may include a hollow and sealed tank body 41. The tank body 41 is provided with an inlet pipe 42 connected to the mixer 1, and on the top of the tank body 41 is provided an exhaust pipe for discharging the gas after preliminary separation. 5. At the bottom of the tank body 41 is provided a first sand discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com