Decorative concrete overhanging eave formwork

A concrete and decorative technology, applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., which can solve the problems of unreasonable design of drip groove and unsolved one-time molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

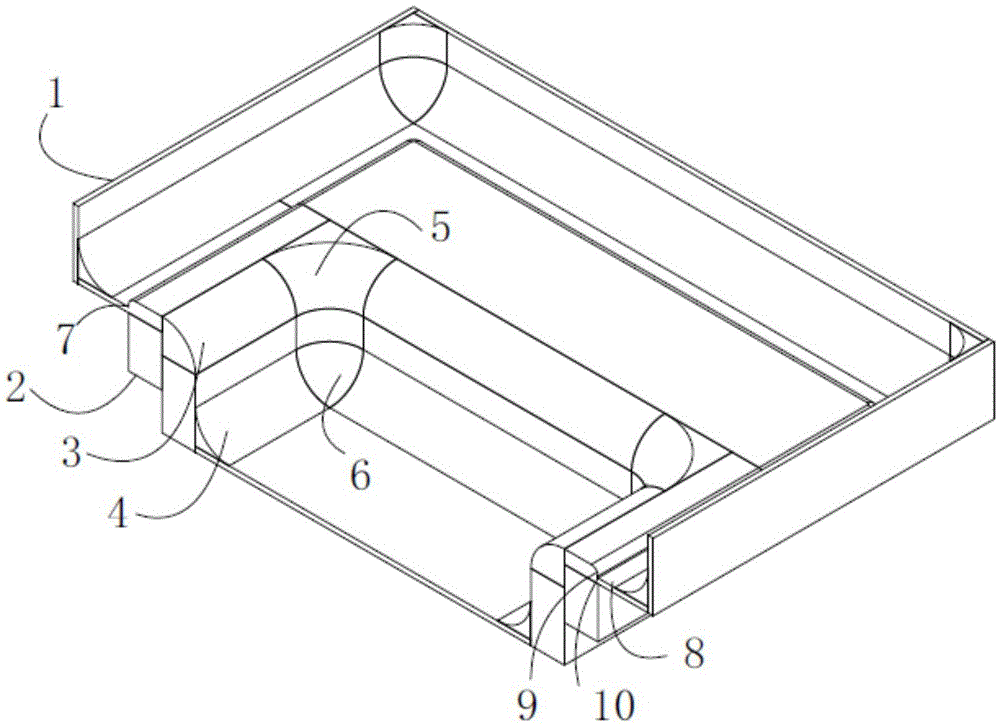

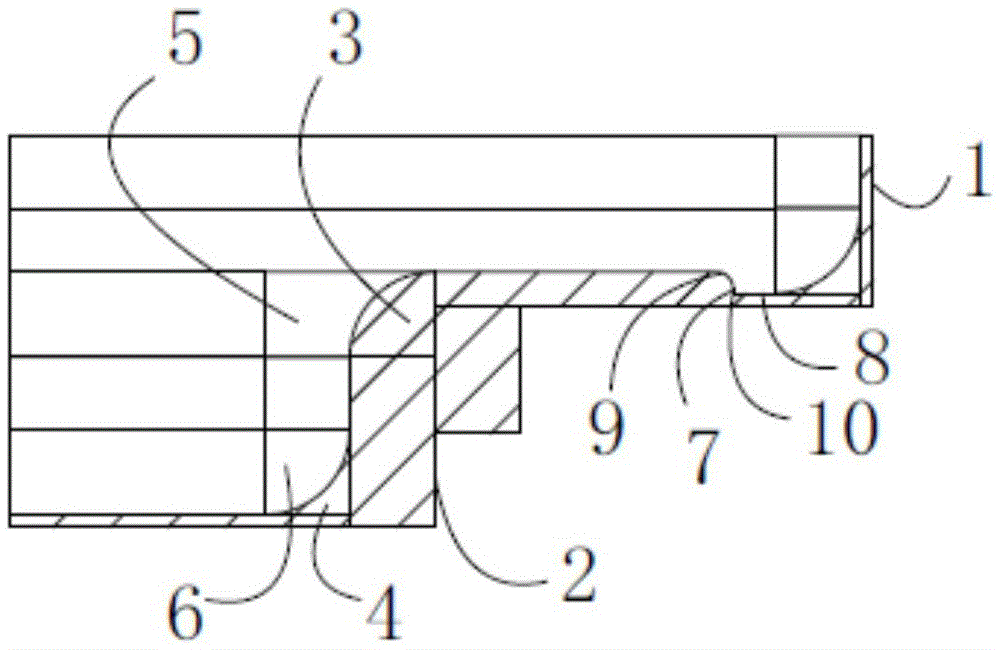

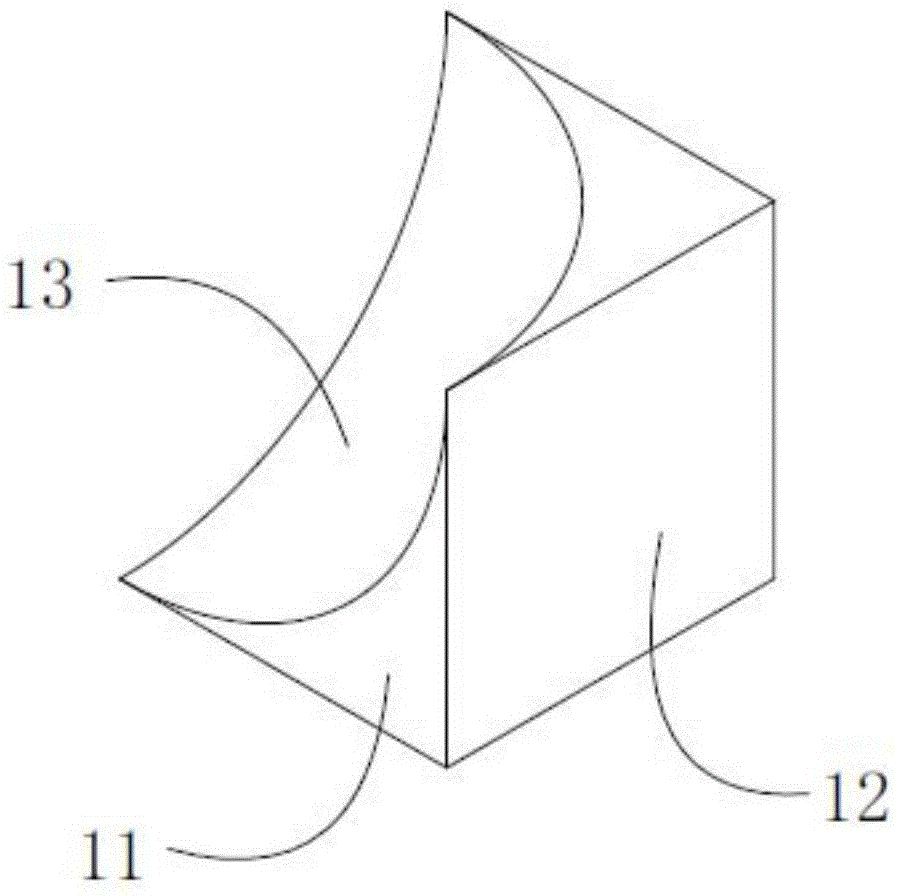

[0022] figure 1 It is a structural schematic diagram of a decorative concrete cornice formwork, figure 2 It is a structural sectional view of a decorative concrete cornice formwork. Such as figure 1 and figure 2 As shown, a decorative concrete cornice formwork is provided in this embodiment, including baffles, keels 2, inner corner wooden lines 3, outer corner wooden lines 4 and brackets enclosed in the concrete cornices to be poured. In the example, according to the design drawing of the concrete cornice board, the baffle plate 1, the inner corner wooden line 3, and the outer corner wooden line 4 that have been made are fixed through the keel 2 and the bracket, and the construction is carried out according to the construction plan. To operate in order, first set up the bracket and the keel 2, support the baffle plate 1 through the keel 2 and fix it, and then arrange the internal angle wooden lines 3, internal angle wooden lines 5, When arranging the male corner wooden t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com