Construction method for quickly pouring anti-slide pile protection wall concrete

A construction method and concrete technology, applied in excavation, foundation structure engineering, construction, etc., can solve problems affecting the progress of excavation of anti-slide piles, quality and safety hazards of retaining walls, and gaps in concrete quality, so as to eliminate hidden dangers in the quality of retaining walls , Good wall quality control and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

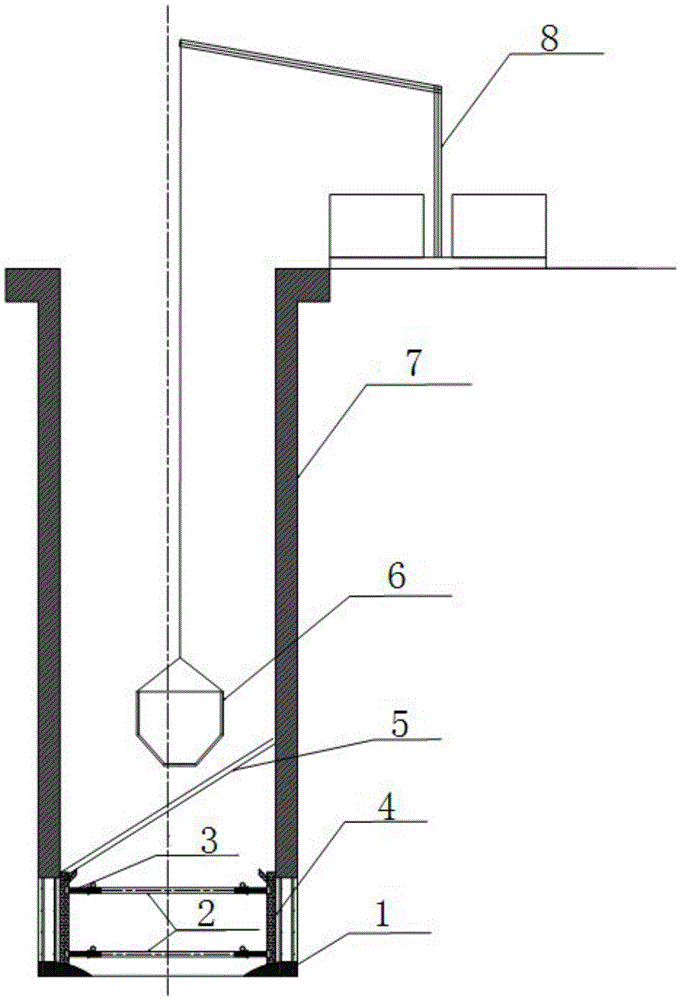

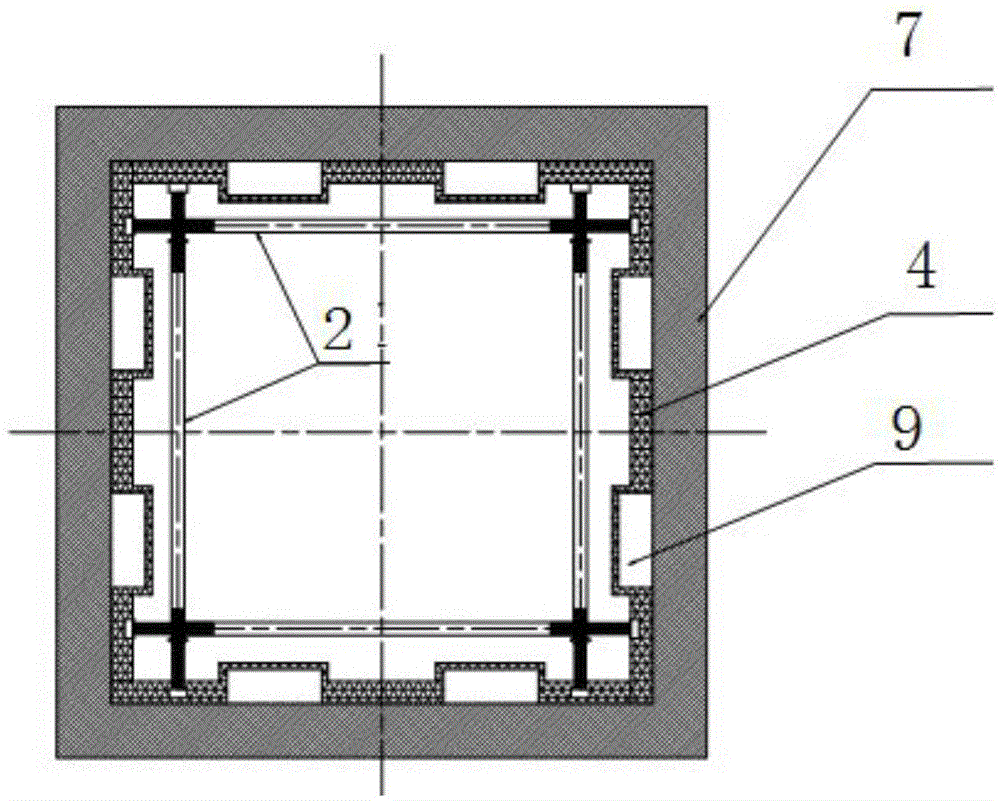

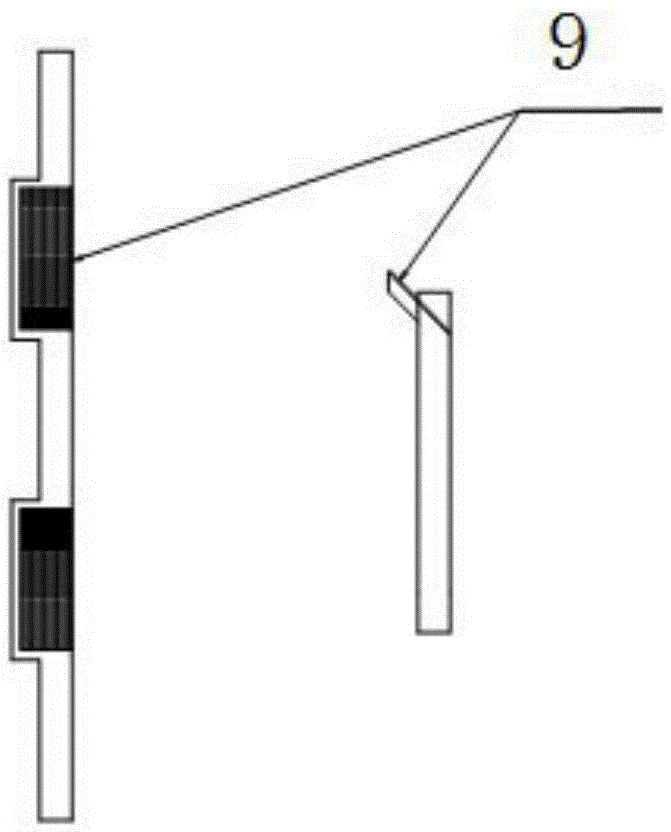

[0022] Such as Figure 1-3 As shown, the anti-slide pile retaining formwork support and concrete pouring structure, the structure includes sand cushion bottom mold 1, supporting steel pipe 2, adjusting screw 3, retaining formwork 4, chute 5, concrete bucket 6, anti-slide pile Retaining wall 7, lifting hoist 8; both ends of the supporting steel pipe 2 are respectively connected with the adjusting screw 3, the adjusting screw 3 is fixed on the retaining wall template 4, and the retaining wall template 4 is installed on the bottom mold 1 of the sand cushion layer; the anti-sliding pile retaining wall 7 is set On the retaining formwork 4, a chute 5 is installed on the inner wall of the anti-slide pile retaining wall 7, the chute 5 corresponds to the position of the concrete bucket 6, and the concrete to be poured is placed in the concrete bucket 6; the concrete bucket 6 Link to each other with lifting winch 8.

[0023] The supporting steel pipes 2 are sequentially connected to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com