Paper Plastic Shaping Machine and Its Shaping Process

A paper-plastic shaping machine and hot-press shaping technology, used in textiles and papermaking, etc., can solve problems such as low efficiency, affecting service life, and station deviation, and achieve the functions of easy assembly and replacement, prolong service life, and precise positioning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

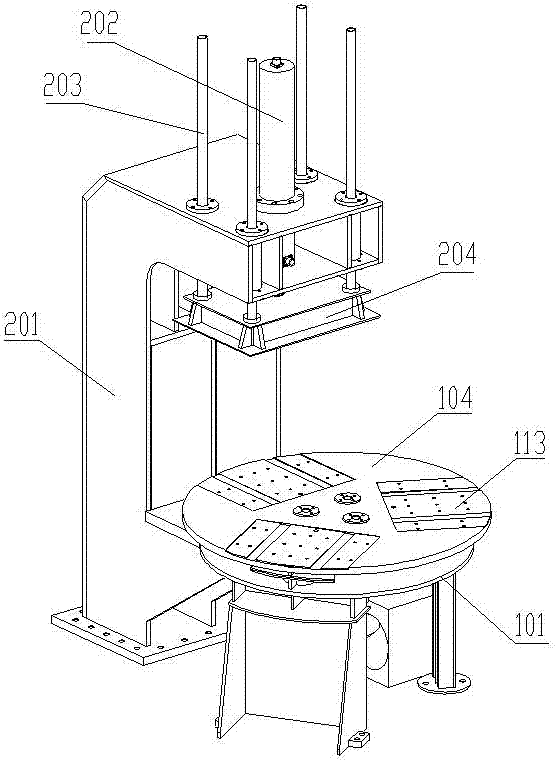

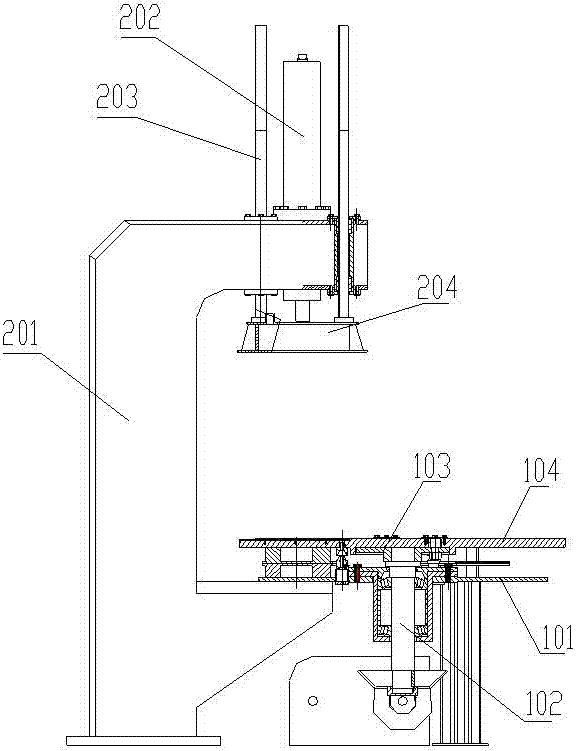

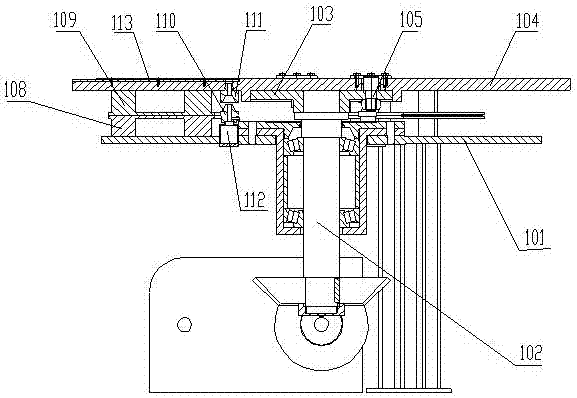

[0035] see Figure 1~7 , a paper-plastic shaping machine related to the present invention, said paper-plastic shaping machine includes an upper mold assembly for installing an upper mold and a lower mold assembly for installing a lower mold, and the lower mold assembly includes a turntable frame 101 A rotating shaft 102 is vertically installed on the turntable frame 101, and the top of the rotating shaft 102 is connected with a key to cover a rotating connection plate 103, and a plurality of guide columns 105 are installed vertically upward on the rotating connecting plate 103, and the turntable 104 rests on the rotating connection plate 103, and the rotating plate 104 is provided with a connection hole for inserting the guide column 105, the guide column 105 is covered with a lubricating sleeve 106, and the lubricating sleeve 106 is located between the guide column 105 and the inner wall of the connection hole Between (preferably, the lubricating sleeve 106 is a graphite lubr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com