Roll paper leveling device

A technology of roll paper and leveling mechanism, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc. Better flat effect, easy to use, and ensure the effect of paper quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

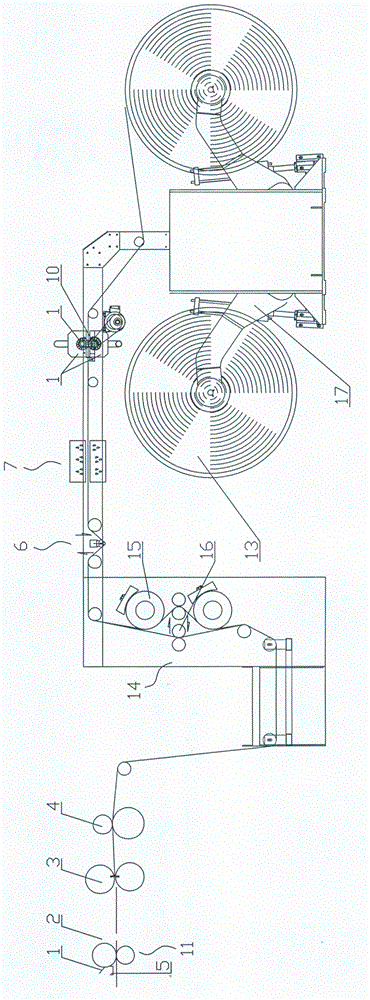

[0017] Referring to the accompanying drawings, the leveling mechanism of this kind of web includes a material rack 17, an anti-warping device 6, a humidifying device 7 for humidifying the paper, a dehumidifying device 14 used in conjunction with the humidifying device, a floating dust removal device 12, an electrostatic The dust removal device 11, the conveying device 4 and the electric controller, the anti-warping device 6 is arranged between the humidifying device 7 and the dehumidifying device 14, and the humidifying device 7 and the dehumidifying device 14 are connected with the electric controller controlling their startup, The electric controller is also connected to the conveying device 4, that is, the electric controller calculates the size of the roll paper according to the length of the conveying device 4 conveying the roll paper, and activates the humidifying device 7 and the dehumidifying device 14 according to preset settings. The anti-warping device is a prior art...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com