Discharging and conveying device of punching production line

A transmission device and production line technology, applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of not being able to meet stamping parts transmission, increase labor intensity and risk factors of workers, and achieve elongation and increase transmission distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

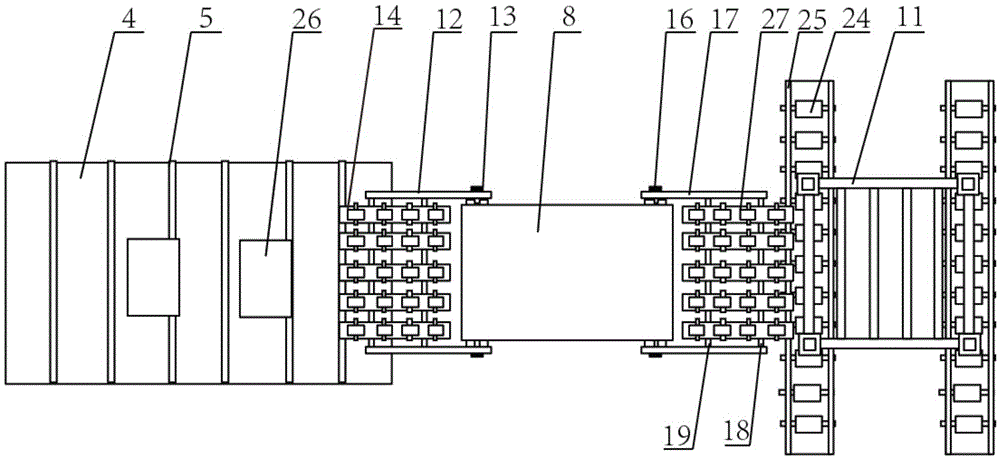

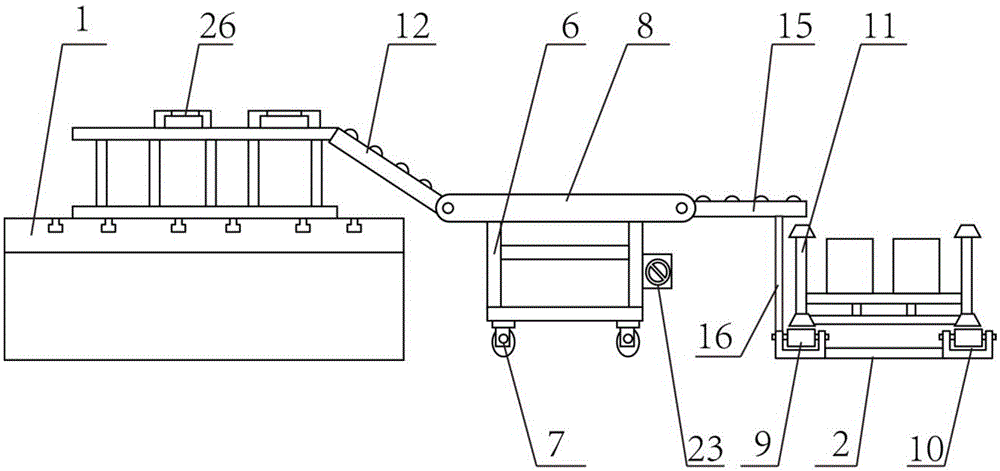

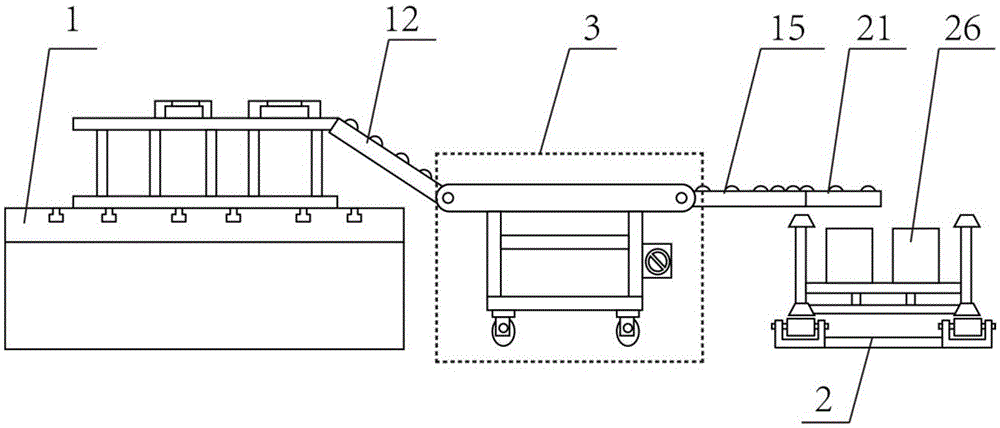

[0032] A discharge conveying device for a stamping production line, comprising a discharge platform 1 and a conveying track 2, the discharge conveying device also includes a conveying trolley 3, the height of the discharge platform 1 is greater than the height of the conveying trolley 3, and the discharge platform 1 Including a support platform 4 and a roller I5 arranged on the support platform 4, the transfer trolley 3 includes a car body 6, wheels 7 arranged under the car body 6 and a conveyor belt 8 arranged on the car body 6, and the transfer track 2 is provided with two rows of rollers, namely roller II 9 and roller III 10, and the transfer track 2 is also provided with a transfer box 11, the height of the transfer box 11 is smaller than the height of the transfer trolley 3, and the discharge platform 1 There is a mobile platform I12 between the transmission trolley 3, and the mobile platform I12 is set obliquely. The left end of the mobile platform I12 rests on the discha...

Embodiment 2

[0036] A method for using a discharge conveying device of a stamping production line, comprising the following steps:

[0037] (1) The stamping part 26 moves to the left end of the mobile platform I through the roller I, and under the action of the inclination angle of the mobile platform I and the transmission shaft I on the mobile platform I, the stamping part slides from the left end of the mobile platform I to the right end of the mobile platform I;

[0038] (2) The stamping parts fall on the conveyor belt of the transmission trolley, and move to the mobile platform II under the drive of the conveyor belt. Under the action of the transmission shaft II, the stamping parts move to the end of the fixed transmission shaft II, and fall into the transmission box close to the transmission trolley On one side, at this time, the movable transmission shaft II does not move relative to the fixed transmission shaft II under the action of the limit device.

Embodiment 3

[0040] When the transfer box is full near the side of the transfer trolley, the method of using the discharge transfer device of the stamping production line includes the following steps:

[0041] (1) The stamping part 26 moves to the left end of the mobile platform I through the roller I, and under the action of the inclination angle of the mobile platform I and the transmission shaft I on the mobile platform I, the stamping part slides from the left end of the mobile platform I to the right end of the mobile platform I;

[0042](2) The stamping parts fall on the conveyor belt of the transmission trolley, and move to the mobile platform II under the drive of the conveyor belt. At this time, the limit device loses the limit control of the movable transmission shaft II under the control of the control device, and the movable transmission shaft Driven by the stamping parts, II moves towards the transfer box, and its right end extends above the center of the transfer box, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com