Automatic production device for encapsulation and injection molding of inserts

A technology of production equipment and overmolding, which is applied in the direction of coating, etc., can solve problems such as high cost, failure to meet market demand, and low production efficiency, and achieve the effects of improving production efficiency, saving production time, and streamlining manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

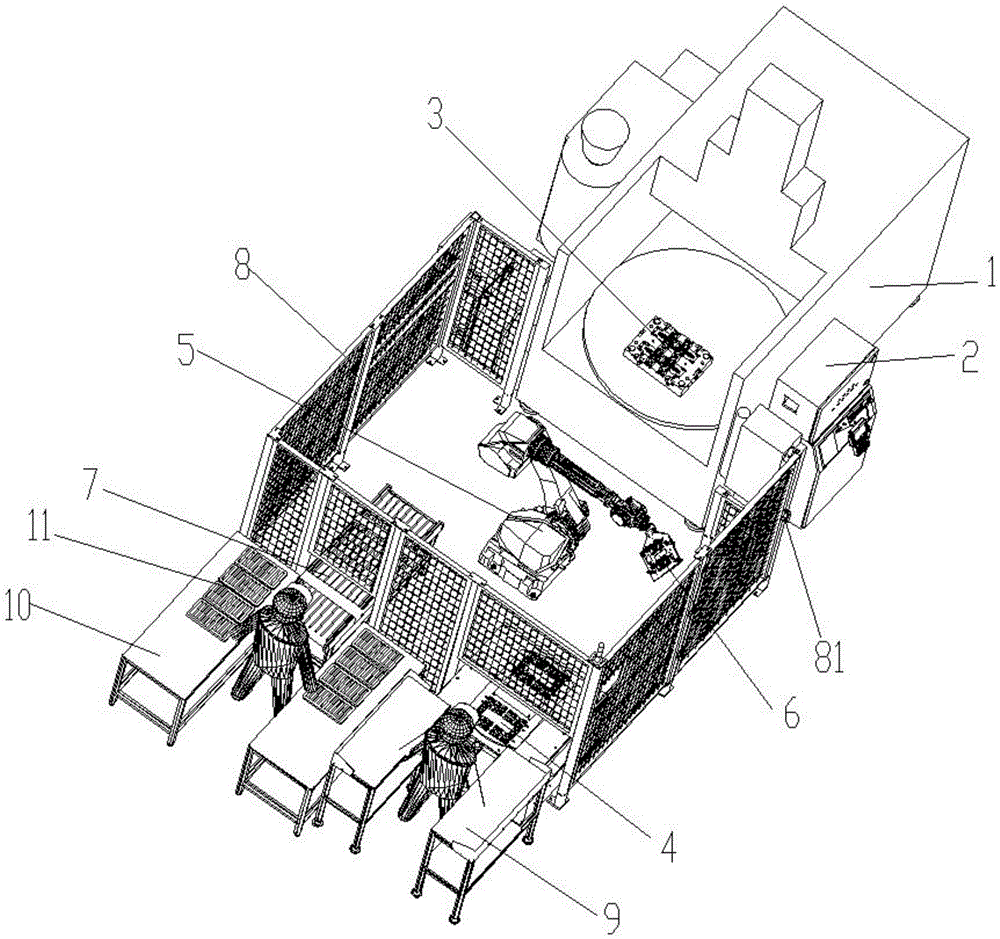

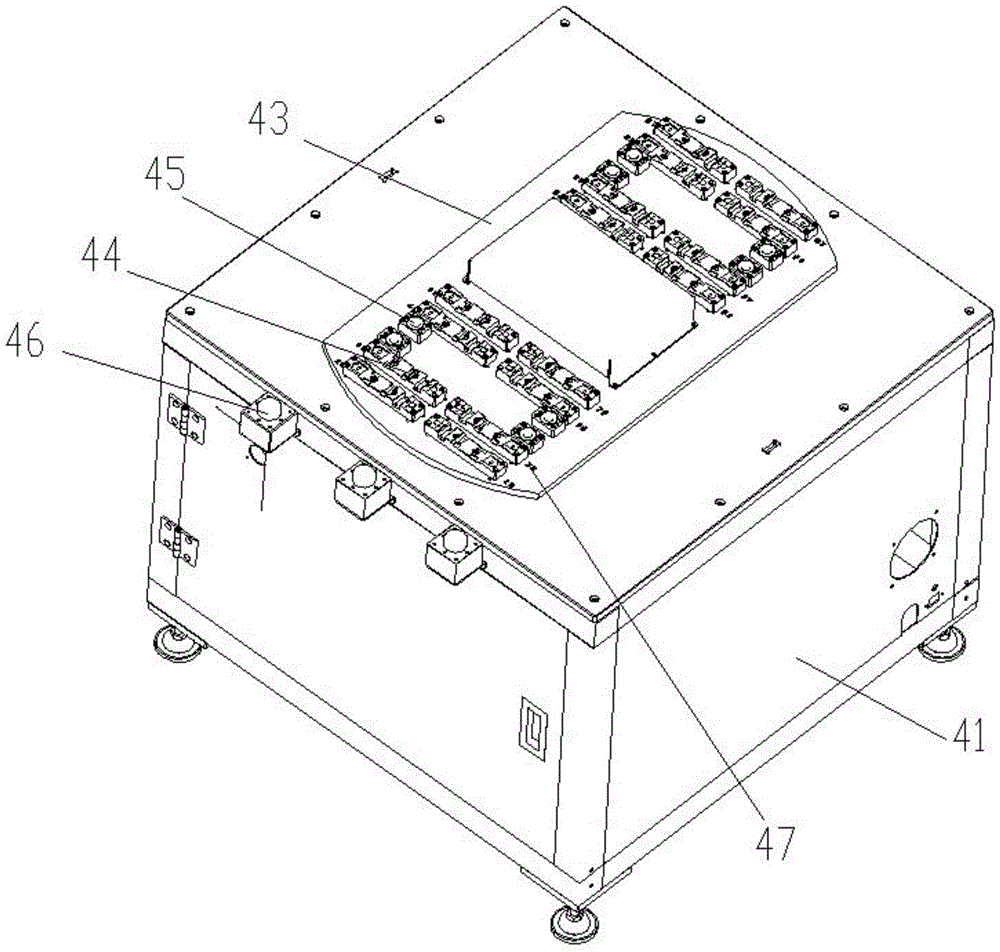

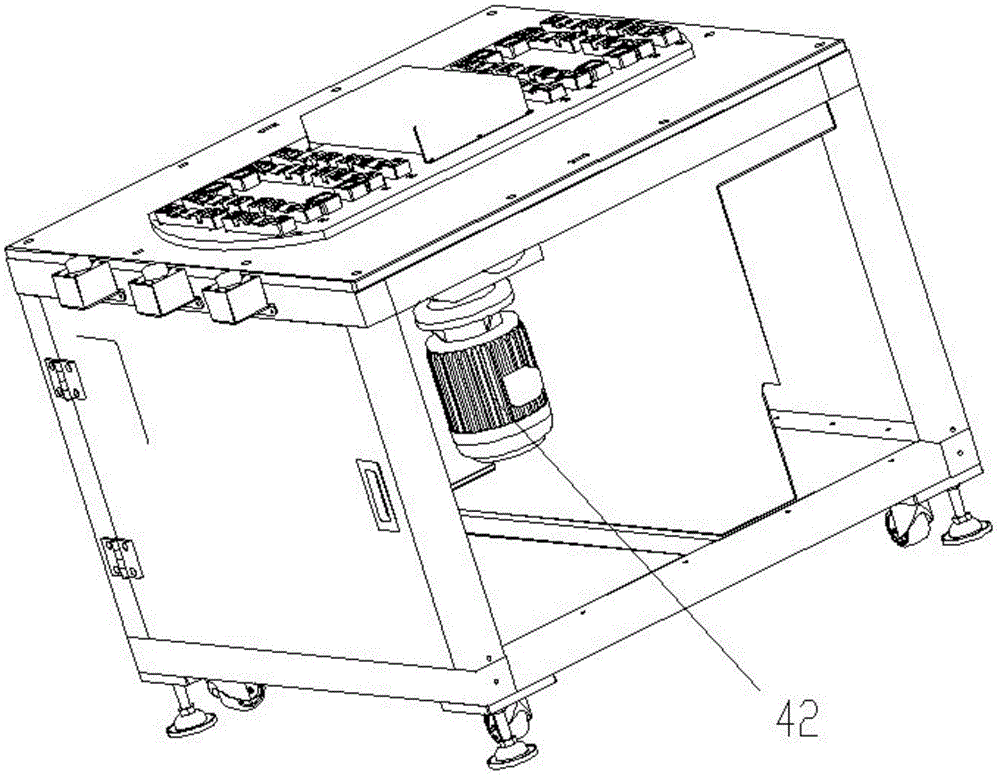

[0028] Embodiment: An automatic production equipment for insert overmolding injection molding, including an injection molding machine 1, a controller 2, a mold 3, a rotary feeding device 4, a feeding robot 5, a product pick-and-place grip 6 and a belt conveyor 7, to use direction as a reference, the mold is installed on the injection molding machine, the controller is placed on the side of the injection molding machine, the rotary feeding device and the belt conveyor are placed side by side at intervals of the injection molding machine In the front, the feeding robot is placed between the injection molding machine and the rotary feeding device, the product pick-and-place gripper is rotatably connected to the feeding robot, the controller is connected to the rotary feeding device, Communication connection between feeding robot and belt conveying device. Through the rotary feeding device, the next batch of inserts to be injected can be prepared in advance during insert injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com