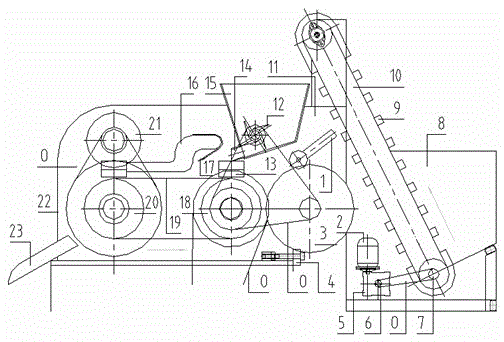

Automatic positioning holding device and automatic splitting machine for areca nuts

An automatic slitting machine and automatic positioning technology, applied in metal processing and other directions, can solve the problems of inaccurate positioning and uneven cutting, and achieve the effect of easy operation, convenient maintenance, and safety and hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

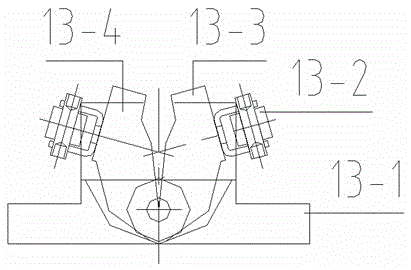

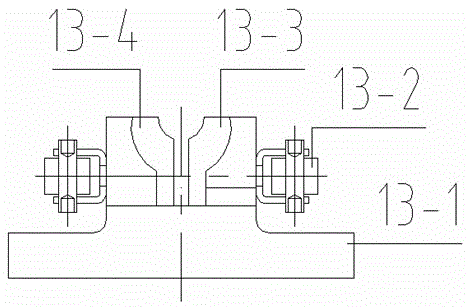

[0033] An automatic positioning and clamping device with accurate positioning and reliable clamping is characterized in that it includes a clamper 13 fixed on the conveyor chain 10 at intervals and an elastic clamper 16 fixed on the frame. The clamper 13 includes a base 13-1 fixedly connected to the conveyor chain, a twin right gripper piece 13-3 and a left gripper piece 13-4 that are movably connected with the base, and are respectively fixed on the right gripper piece, the left gripper Roller assembly 13-2 on the outside of the device sheet; the elastic clamp 16 includes a clamping rod 16-1 fixed on the frame at both sides of the clamping device, and a slope-shaped spring is fixed on the side of the clamping rod Sheet 16-2, a force spring 16-3 is set between the clamping rod and the spring sheet; the roller in the roller combination and the slope-shaped spring sheet on the side of the clamping rod gradually approach during the movement, pushing the twin The right gripper pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com